Construction method of dismantling and constructing natural gas steam reformer tube in different places

A construction method, natural gas technology, applied in the direction of manufacturing tools, metal processing equipment, arc welding equipment, etc., can solve the problem of high relocation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

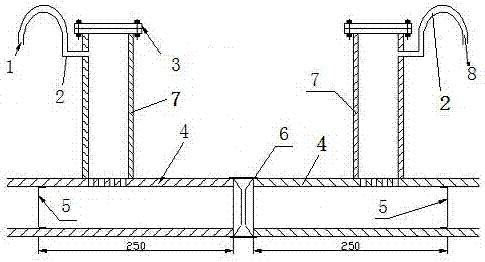

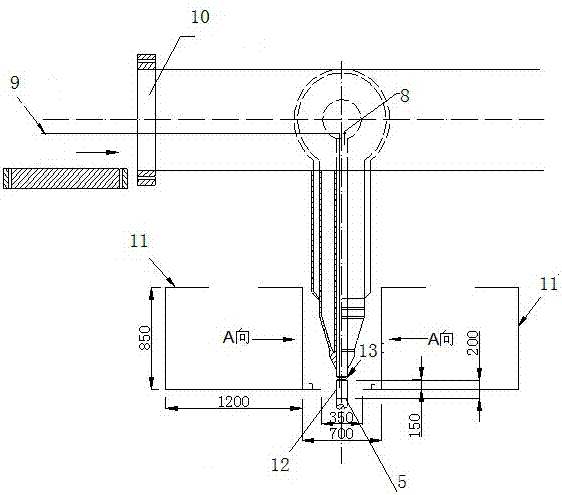

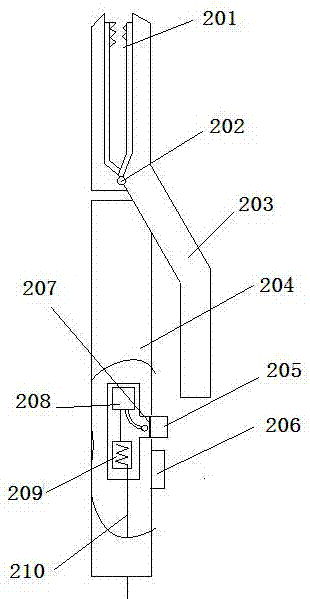

[0021] The construction method of dismantling and constructing the natural gas steam reformer furnace tube in different places, including the dismantling of the lower gas collecting pipe, the dismantling of the lower support, the bevel processing of the welding joint of the lower gas collecting pipe, the butt welding of the lower gas collecting pipe group, the bevel processing of the welding joint of the rising pipe, the bevel processing of the rising pipe Butt welding, pigtail welding.

[0022] The lower air collecting pipe is dismantled, and each row of the lower air collecting pipe is cut into three sections of north, middle and south, among which there are 19 conversion pipes in the north section, 14 conversion pipes and 1 ascending pipe in the middle section, and 19 conversion pipes in the south section; The cut is located at the weld between the overhanging section of the riser and the transition section;

[0023] The north and south in the present invention refer to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com