Intelligent aging system using AGV mobile aging rack

An aging rack and intelligent technology, applied in electric/hybrid, comprehensive factory control, loading/unloading, etc., can solve problems such as electrical or mechanical failure, long downtime for maintenance, complex mechanical design, etc., to achieve labor saving and automation High, easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

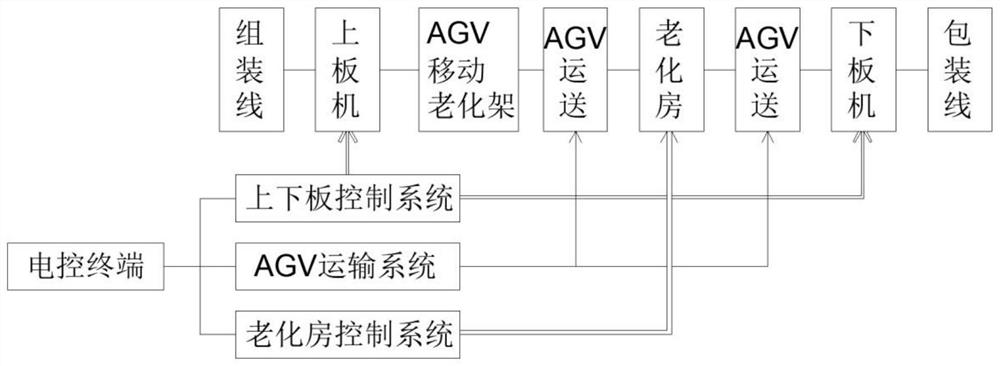

[0052]An intelligent aging system using AGV mobile aging rack, including upper and lower board control system, AGV automatic transportation system, aging room control system and electric control terminal, the upper and lower board control system, AGV automatic transportation system, aging room control system and electric control terminal. All control terminals maintain real-time data communication through the Internet. The electronic control terminal is used to maintain real-time data communication with the upper and lower panel control systems, and is also used to maintain real-time data communication with the AGV automatic transportation system. The aging room control system maintains real-time data communication, the electronic control terminal includes an external main power supply, a display screen, a power storage box and a sensor, the electronic control terminal and the upper and lower panel control systems are electrically connected in both directions, and the electronic...

no. 2 example

[0054] The upper and lower plate control system is used to receive the instructions sent by the electric control terminal, maintain real-time data communication with the electric control terminal, and also control the assembly and packaging operations of the upper and lower plate machines. The control system includes an upper plate machine and a lower plate machine. The upper plate machine is used to connect the assembly line with the AGV mobile aging rack, so that the product enters the aging rack from the assembly line, which is called the upper plate, and the docking machine is the upper plate machine. , the lower plate machine is used to connect the AGV mobile aging rack with the packaging line, so that the product is moved from the aging rack to the packaging line, which is called the lower plate, and the docking equipment is the lower plate machine, the upper plate machine, the lower plate A mechanical operation module, an information collection module and an instruction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com