Double-track four-crane conveyor

A transporter, double-track technology, applied in cranes, transportation and packaging, etc., can solve problems such as difficulty in dragging the bracket, difficult to control the position, and insufficient installation of the bracket in place, so as to achieve reliable lifting stability, low relocation cost, and structural integrity. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Accompanying drawing is embodiment of the present invention.

[0021] Below in conjunction with accompanying drawing, content of the invention will be further described:

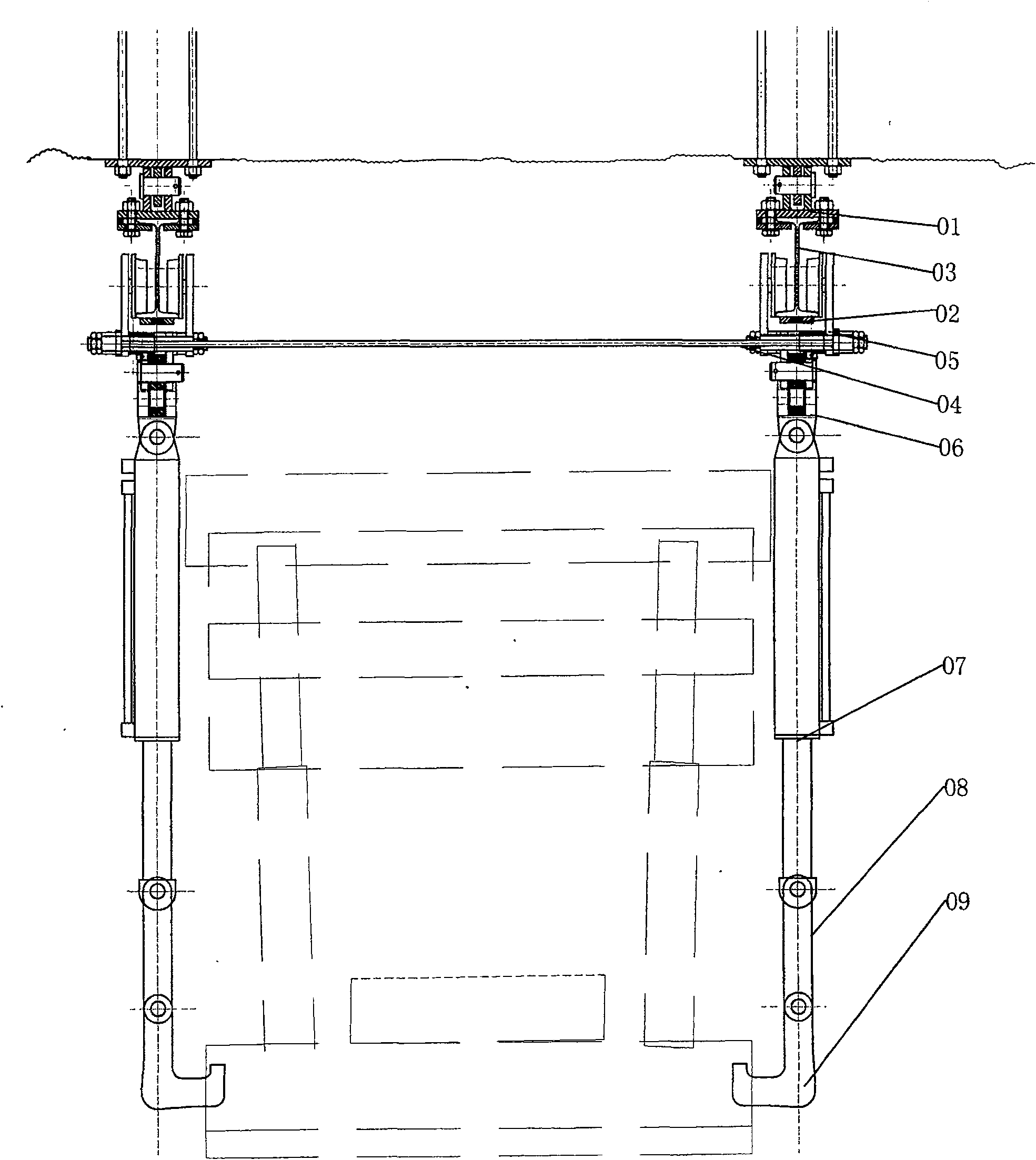

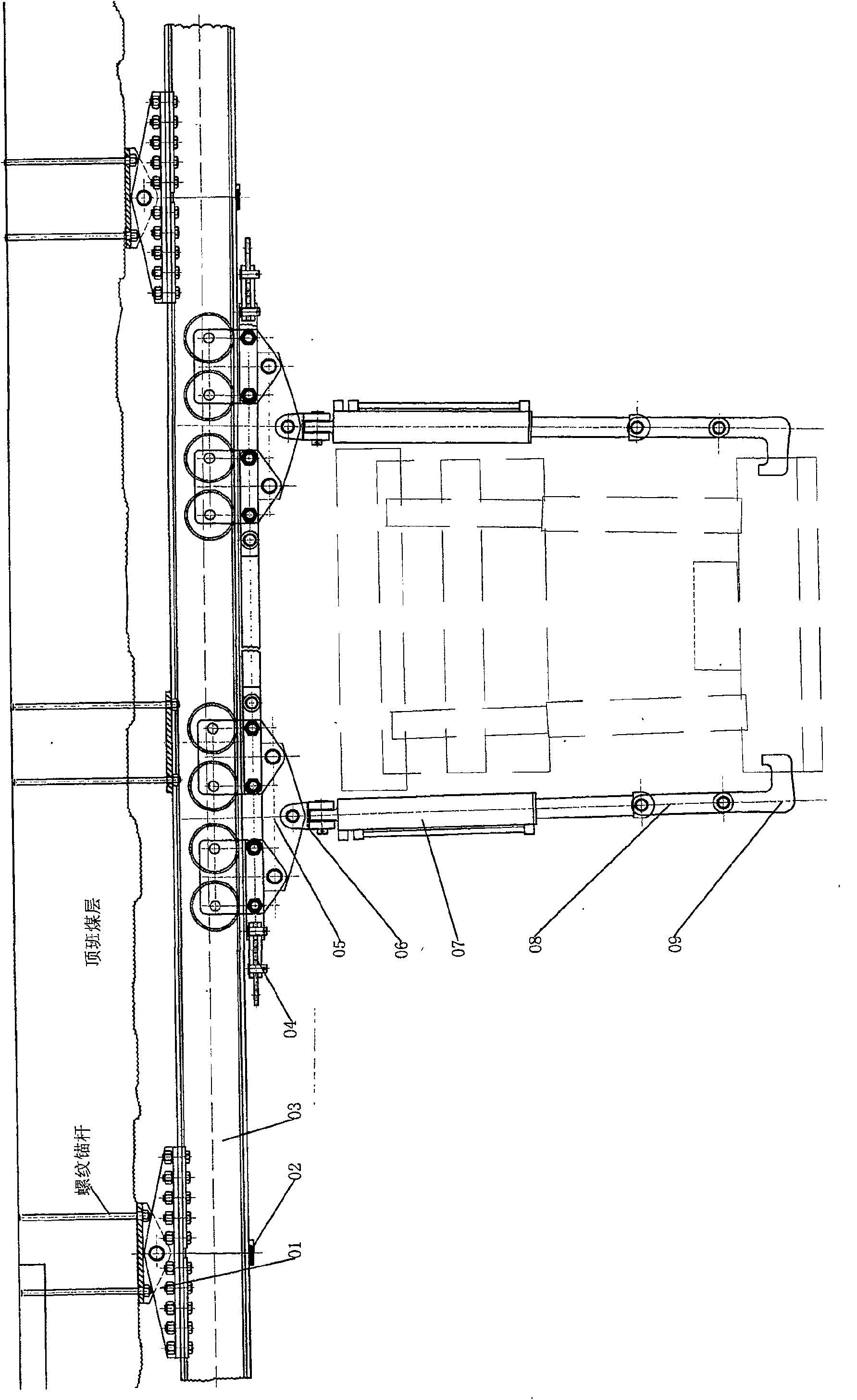

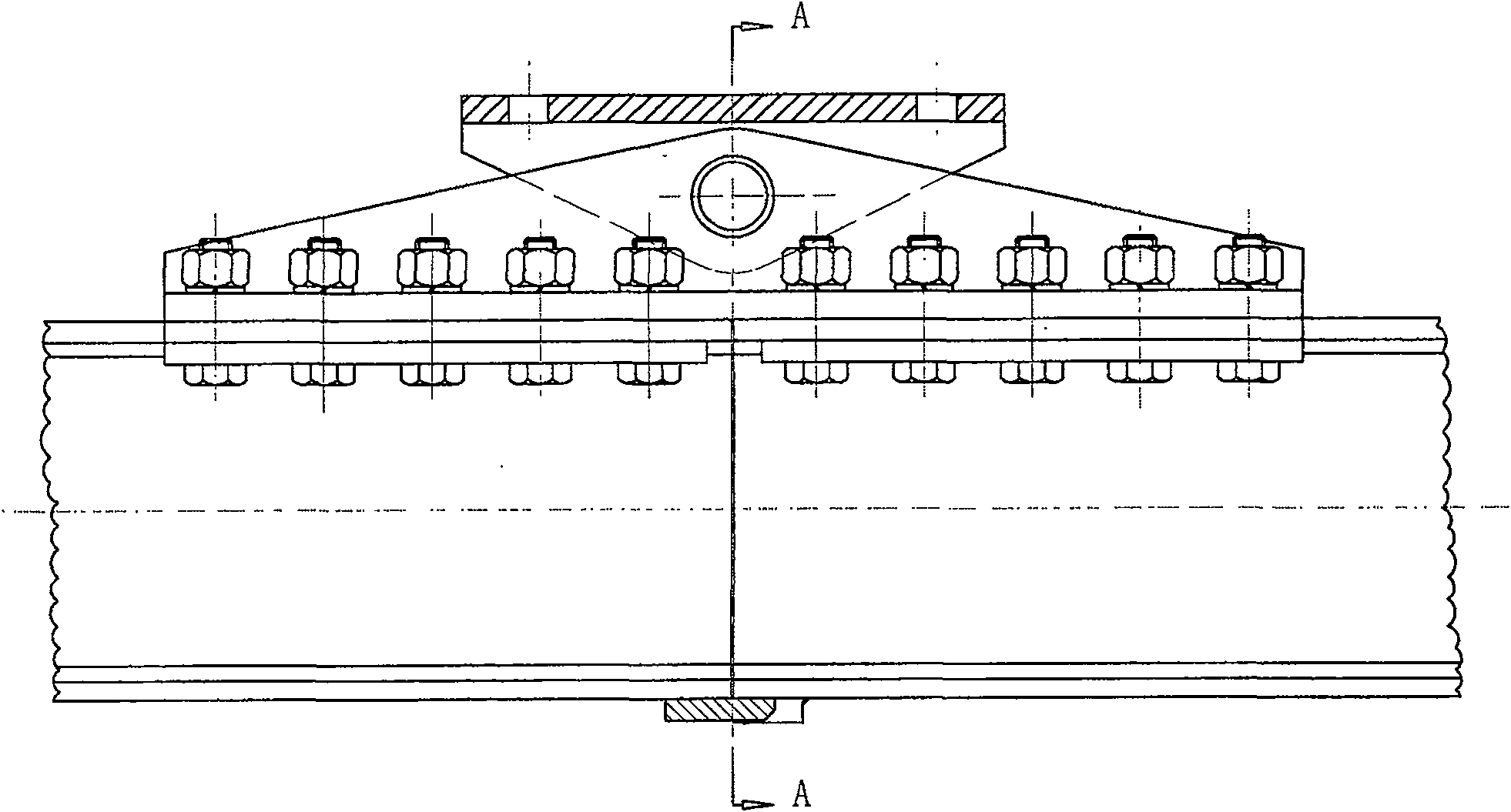

[0022] refer to figure 1 , figure 2 As shown, the upper edge of the track 03 is connected to the track fixing mechanism 01, and the lower edge is slidingly connected to the wheel set mechanism 05 and the traction mechanism 04. The wheel set mechanism 05 is connected to the cross joint 06, and the cross joint 06 is connected to the lifting cylinder 07. , the piston rod in the lifting cylinder 07 is connected with the hook connecting pull 08, the hanging hook connecting pull 08 is connected with the lifting hook 09, the track fixing mechanism 01 is connected with the anchor rod device, and the anchor rod device is fixedly connected with the coal seam roof. The lifting cylinder 07 and the piston rod are connected with the lifting hook through the hydraulic system, and the lifting cylinder 07 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com