Four-branch swallow-shaped five-axis machining equipment

A processing equipment and four-branch technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of singular structure of parallel mechanism, small flexible space of machine tools, inconsistent rigidity, etc., and achieve large working load and consistency Good, the effect of driving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

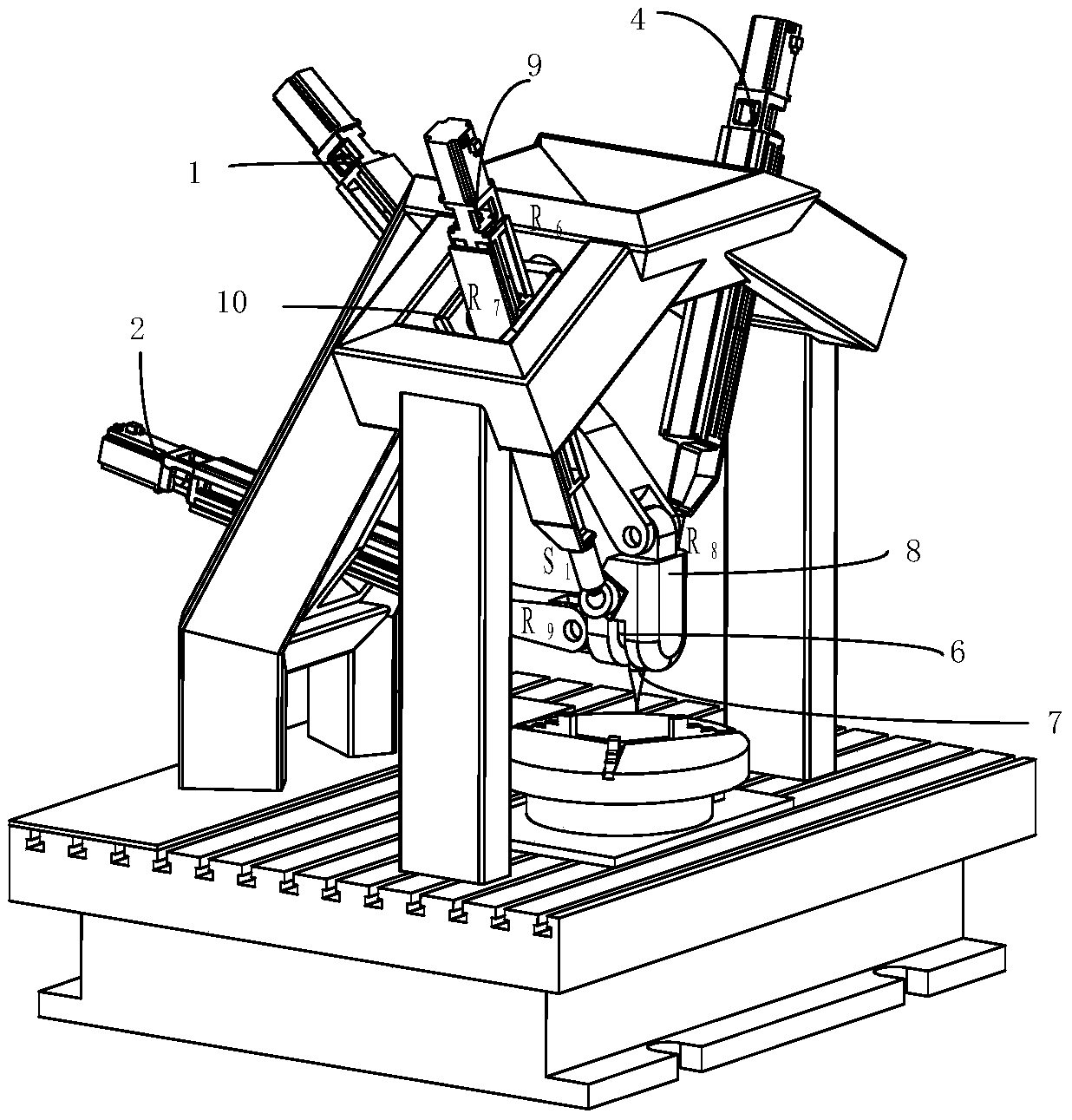

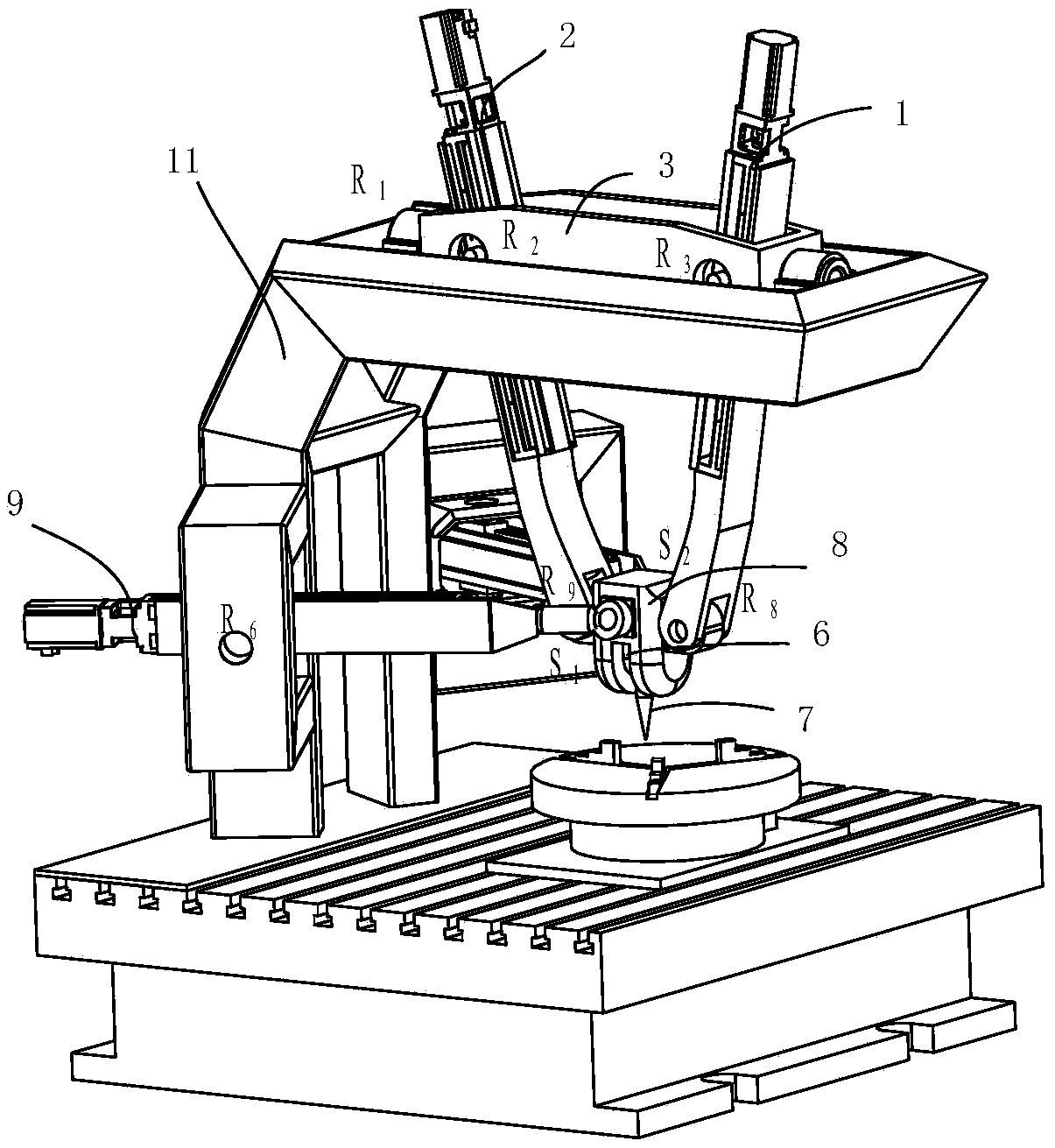

[0022] exist figure 1 and figure 2 In the schematic diagram of the four-branch swallow-shaped five-axis processing equipment shown, the frame 11 is composed of a door-shaped front frame and a bow-shaped rear frame connected to it as a whole, and the first rotating frame 3 is arranged at the rear of the bow-shaped frame of the frame. In the frame, the first rotating frame passes through the rotating pair R 1 It is connected with the frame, the axis of the rotating pair is located in the left and right symmetrical plane of the frame and the included angle with the plane of the worktable is 45° to 90°, the linear modules of the first linear drive branch a1 and the first linear drive branch b2 slide Both ends of the block pass through the rotating pair R 2 and R 3 Connected with the upper and lower ends of the first rotating frame, one end of the two first linear drive branches is the drive motor, and the other end is passed through the rotating pair R 8 and R 9 Connected wi...

Embodiment 2

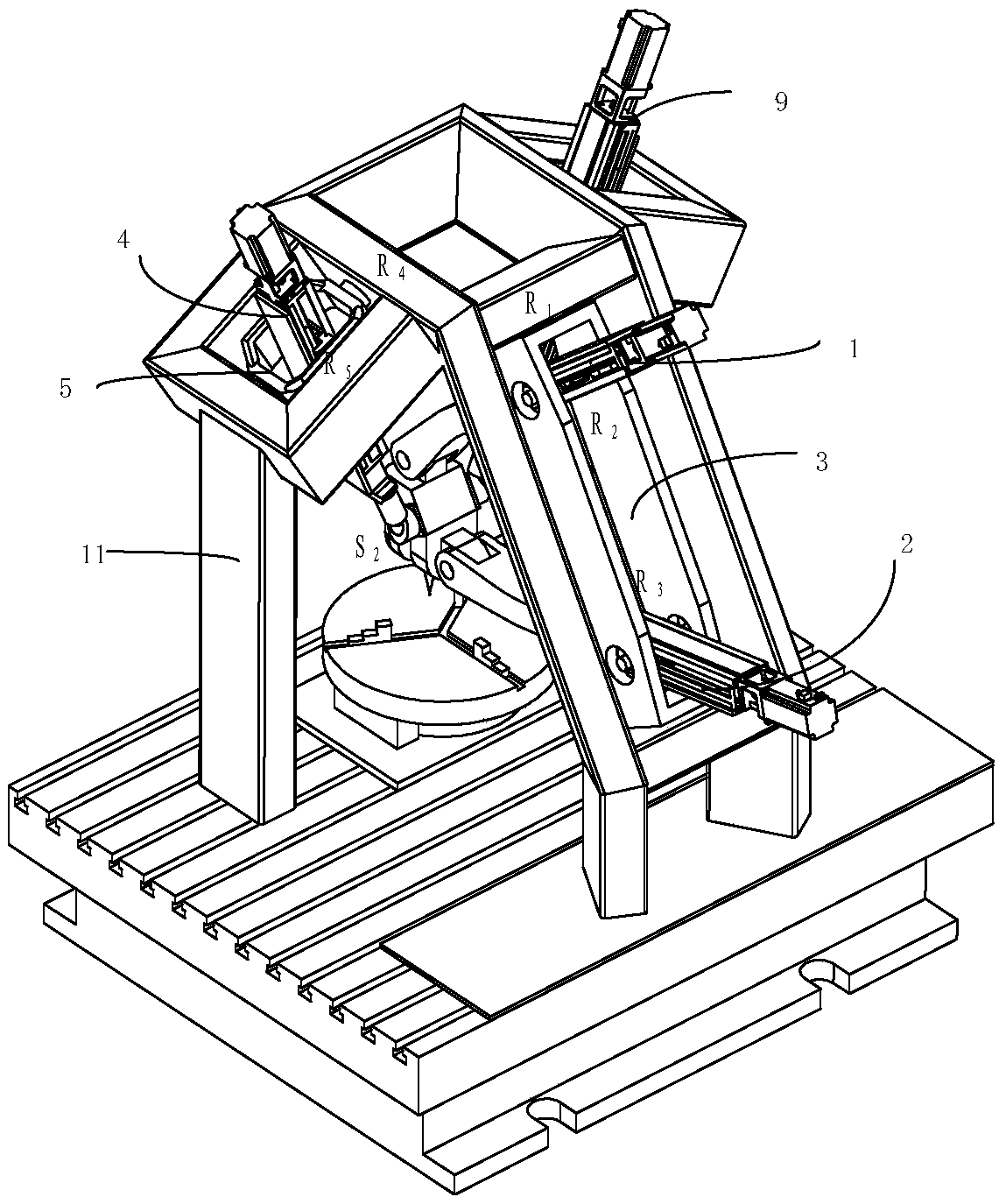

[0024] Such as image 3 and Figure 4 As shown, the frame 11 is a bow-shaped frame, and the first rotating frame 3 is arranged in the left and right symmetrical planes on the top of the bow-shaped frame of the frame. The first rotating frame passes through the rotating pair R 1 It is connected with the frame, the axis of the rotating pair is located in the left and right symmetrical plane of the frame and the included angle with the plane of the worktable is 0° to 45°, the linear modules of the first linear drive branch a1 and the first linear drive branch b2 slide Both ends of the block pass through the rotating pair R 2 and R 3 Connected with the upper and lower ends of the first rotating frame, one end of the two second linear drive branches is the drive motor, and the other end is passed through the rotating pair R 8 and R 9 Connected to the upper and lower ends of the moving platform, the axes of the four rotation pairs in the two first linear drive branches are paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com