Sludge homogeneous slurrying and thermal hydrolysis reaction integrated device

A technology of thermal hydrolysis and pulping, which is applied in water/sludge/sewage treatment, pyrolysis sludge treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problems of uneven pulping, sludge specific resistance and The capillary water absorption index is difficult to reach the dehydration index, and the setting is complicated, so as to promote uniformity, avoid the complicated setting of the hydrothermal reactor device, and the effect of easy tumbling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

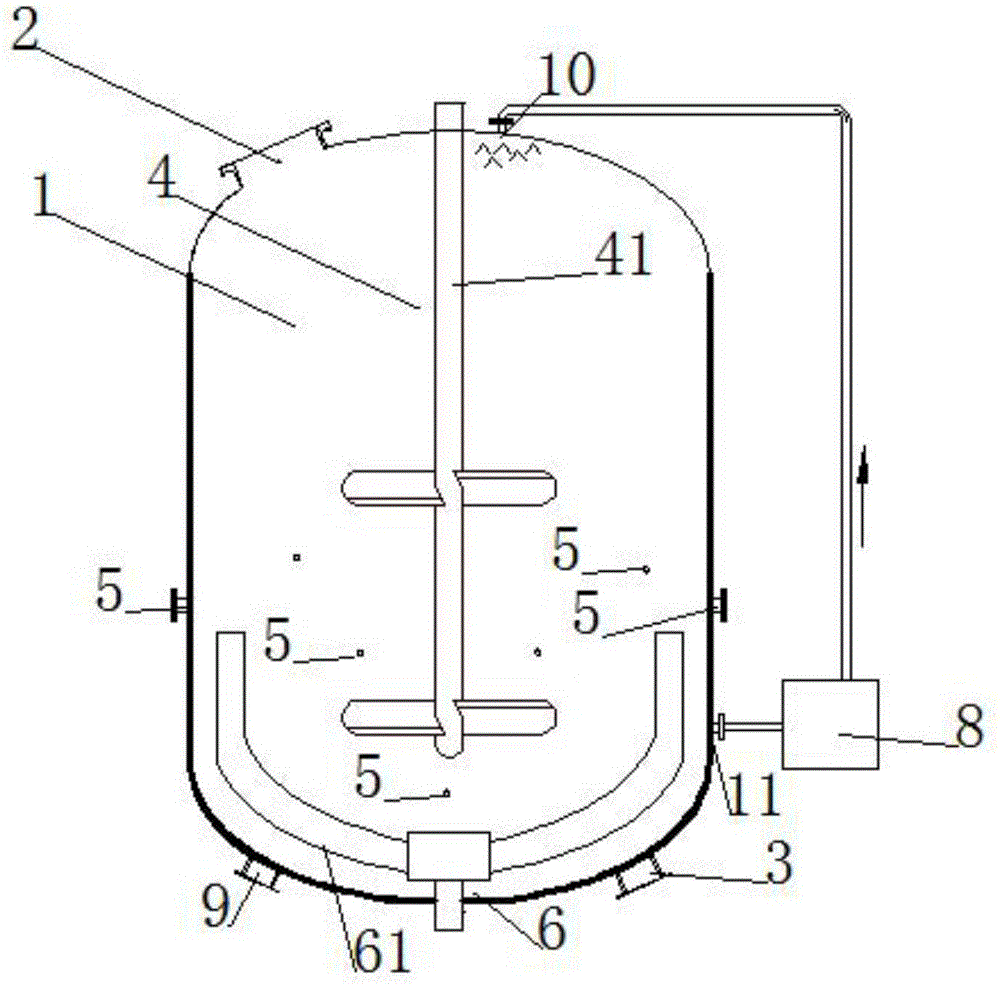

[0033]The invention provides an integrated device for sludge homogeneous slurrying and thermal hydrolysis reaction. A tank body 1 is provided with a feed port 2 and a discharge port 3 at the upper and lower parts of the tank body 1 respectively. The port 2 and the discharge port 3 are respectively connected with a first sealing member and a second sealing member; the first agitator 4 is located in the tank body 1 and includes a first agitating shaft 41, the first agitating shaft 41 protrudes from the top of the tank body 1 and is connected to the first driving mechanism, and the shaft seal between the first stirring shaft 41 and the tank body 1; also includes several steam ports 5 distributed in the tank body Body 1, used to pass steam into the tank body 1; the second agitator 6, located in the tank body 1, includes a second stirring shaft 61, and the second stirring shaft 61 extends out of the tank The bottom of the body 1 is connected with the second driving mechanism, and t...

Embodiment 2

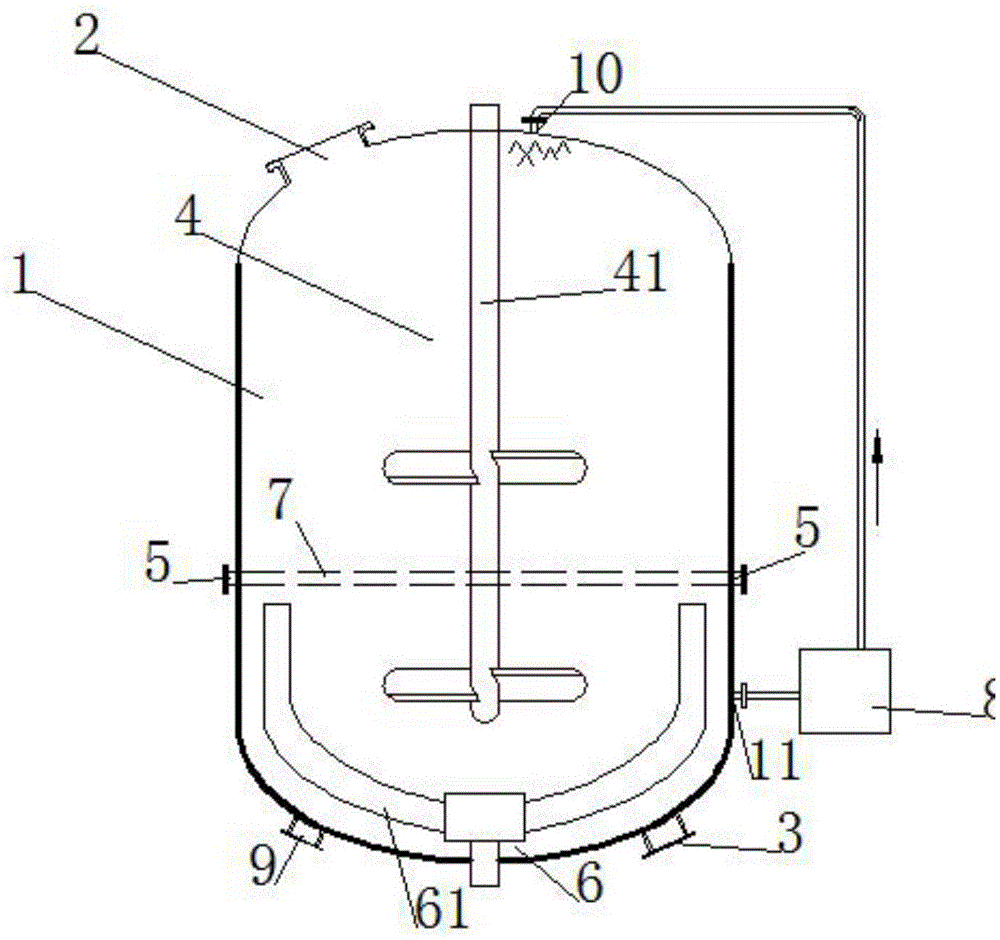

[0046] Such as figure 2 As shown, this embodiment provides an integrated device for sludge homogeneous slurrying and thermal hydrolysis reaction, which is an improvement made on the basis of Embodiment 1. Compared with the technical solution of Embodiment 1, it is different The only thing is that: the several steam ports 5 are evenly spaced and located at the same height on the tank body 1; connected, and the annular steam pipe 7 is provided with several steam outlets, at the same time, the steam outlet is arranged in a hole shape, preferably a round hole shape, and the steam outlets are in two rows on the annular steam pipe 7, And uniformly arranged, of course, the steam outlet can also be set in other hole shapes and other positions on the annular steam pipe 7 .

Embodiment 3

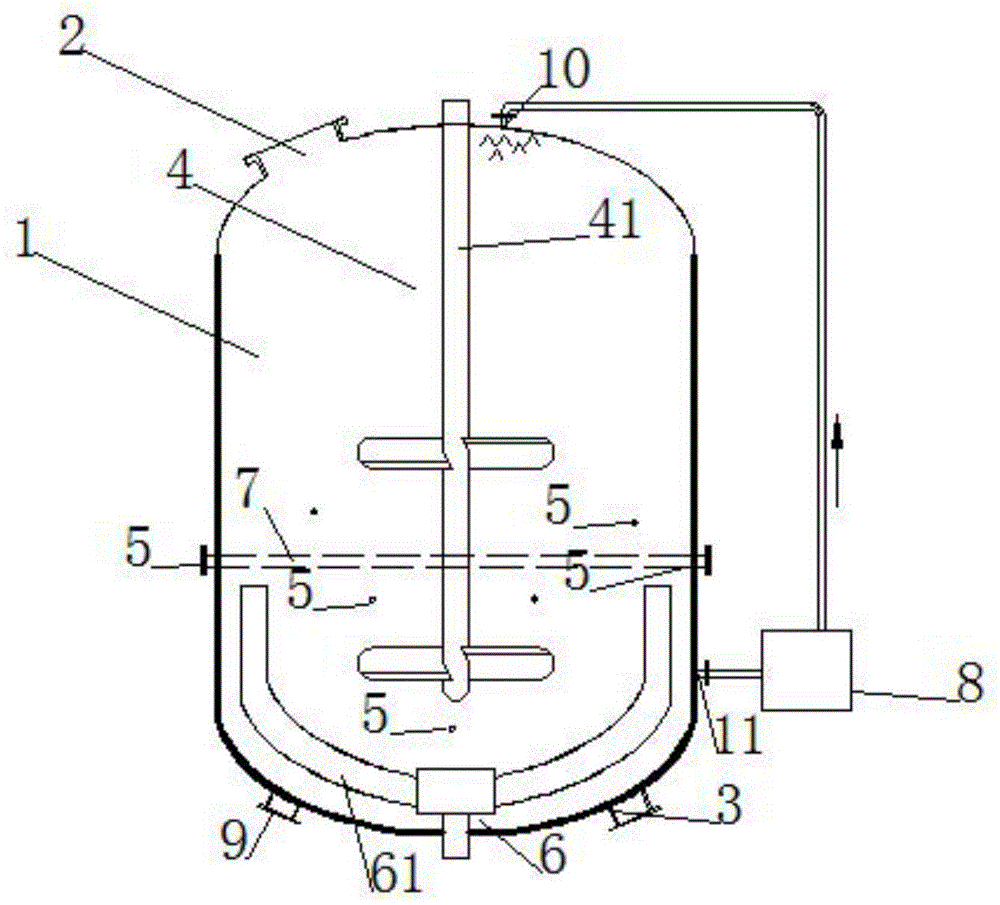

[0048] Such as image 3 As shown, this embodiment provides an integrated device for sludge homogeneous slurrying and thermal hydrolysis reaction, which is an improvement made on the basis of Embodiment 1. Compared with the technical solution of Embodiment 1, it is different Only in that: the several steam ports 5 are evenly spaced, and some of the several steam ports 5 are located at the same height on the tank body 1; A steam port 5 communicates with the annular steam pipe 7 arranged close to the inner wall of the tank body 1, and the annular steam pipe 7 is provided with several steam outlets, and at the same time, the steam outlet is arranged in a hole shape, preferably a circular hole shape, and the steam outlets are in two rows on the annular steam pipe 7, and are evenly arranged. Of course, the steam outlets can also be set in other hole shapes and other positions on the annular steam pipe 7 .

[0049] The following is the use method of the sludge homogeneous slurrying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com