Processing method of non-metal refrigerator middle clapboards

A processing method, a non-metallic technology, is applied in the processing field of non-metallic refrigerator partitions, which can solve the problems of poor cold and heat insulation, and achieve the effects of easy molding and grinding, poor cold and heat conductivity, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for processing a partition in a non-metallic refrigerator, the specific steps are as follows:

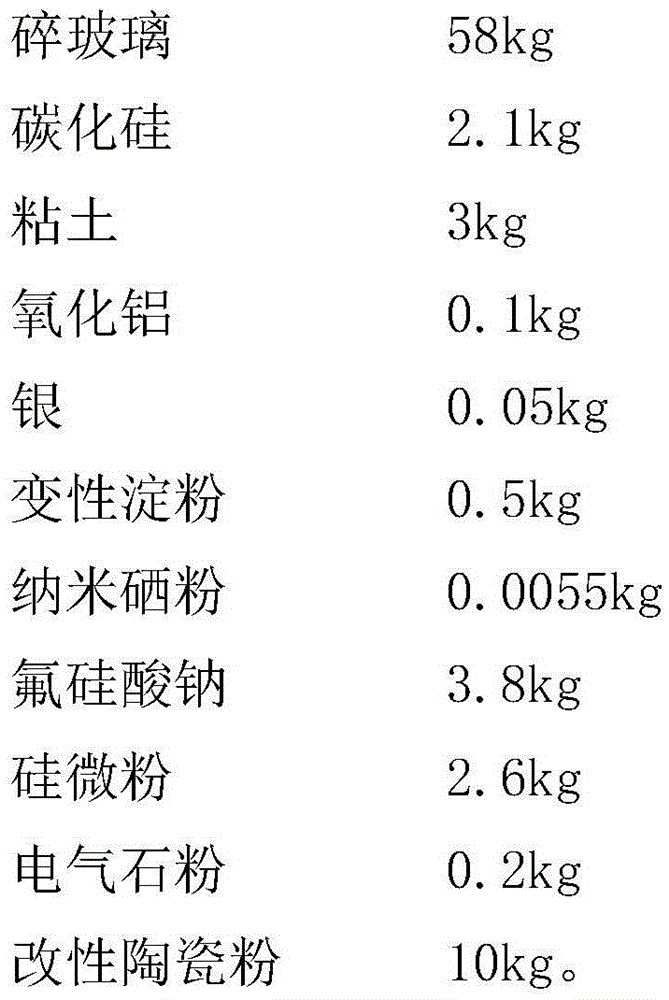

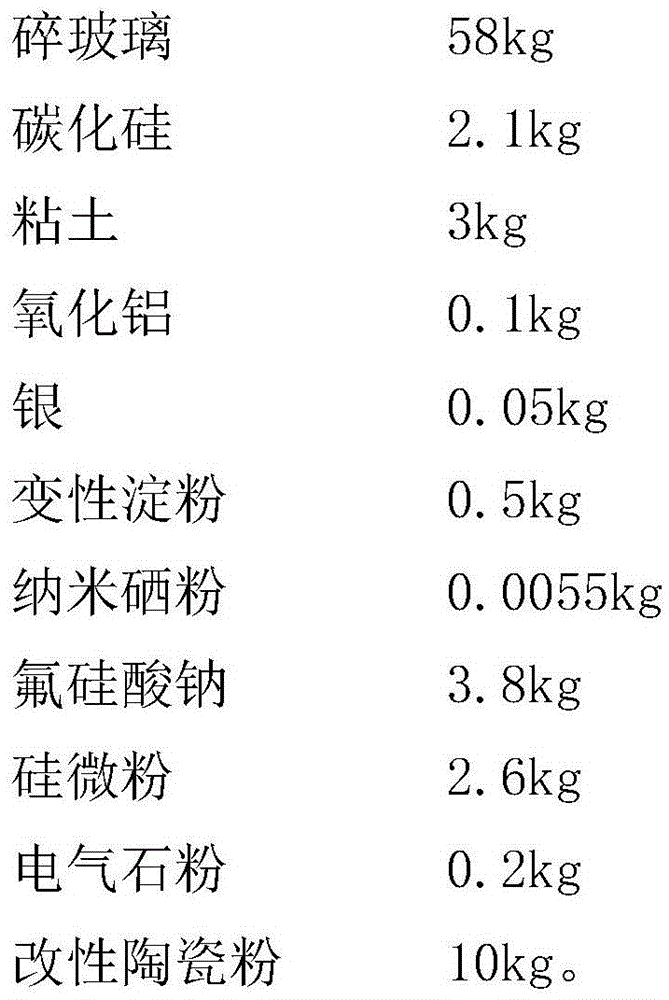

[0025] 1) Purchasing non-metallic raw materials as processing raw materials, and weighing the purchased raw materials after passing the inspection;

[0026] 2) Put the non-metallic raw materials into the ball mill jar, use agate balls as the balls, the mass ratio of the balls to the materials is 6:1, and continue ball milling in the ball mill for 3 hours under the condition that the rotating speed is 140-155 rpm;

[0027] 3) Take out the ground raw materials and put them into an ultrasonic disperser, use ethanol as the medium, and ultrasonically disperse them for 40 minutes, take them out and dry them for later use;

[0028] 4) putting the dried non-metallic raw material in step 3) into a grinder for grinding, passing through a 160-180 mesh sieve to obtain non-metallic raw material powder for use;

[0029] 5) Put the non-metallic raw material powder into the furnace...

Embodiment 2

[0032] A method for processing a partition in a non-metallic refrigerator, the specific steps are as follows:

[0033] 1) Purchasing non-metallic raw materials as processing raw materials, and weighing the purchased raw materials after passing the inspection;

[0034] 2) Put the non-metallic raw materials into the ball mill jar, use agate balls as the balls, the mass ratio of the balls to the materials is 6:1, and continue ball milling in the ball mill for 3 hours under the condition that the rotating speed is 140-155 rpm;

[0035] 3) Take out the ground raw materials and put them into an ultrasonic disperser, use ethanol as the medium, and ultrasonically disperse them for 40 minutes, take them out and dry them for later use;

[0036] 4) putting the dried non-metallic raw material in step 3) into a grinder for grinding, passing through a 160-180 mesh sieve to obtain non-metallic raw material powder for use;

[0037] 5) Put the non-metallic raw material powder into the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com