Dismantling-free high-strength building formwork

A building formwork, high-strength technology, applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of increased construction costs, waste of wood and steel plates, damage and deformation of building formwork without disassembly, and reduce follow-up projects The effect of low volume, poor thermal conductivity, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

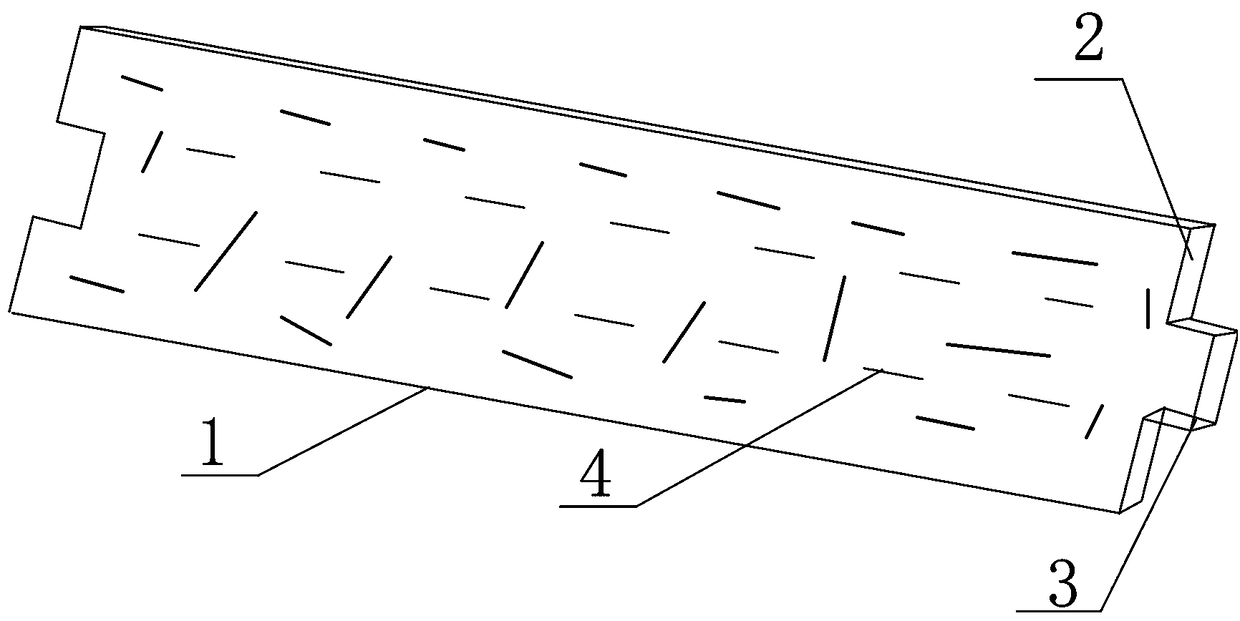

[0016] like figure 1 As shown, a disassembly-free high-strength building formwork includes a mesh surface, a core body, and a connecting structure; the mesh surface 1 is arranged on the surface of the core body 2, and the depth of the surface embedded in the core body 2 is not greater than 3 mm; The mesh surface 1 is made of mesh cloth with mesh, and the core body 2 is formed by mixing and stirring high-strength gypsum powder, fiber 4, additives and water to form a gypsum slurry; the additives include One or more mixtures of stone powder, fine sand, perlite, vermiculite, EPS particles, water reducer and foaming agent, the foaming agent includes surfactant, sodium dodecylsulfonate, One or more mixtures of dialkyl sodium sulfate and hydrogen peroxide, the fiber length is 16mm, the weight percentage of fiber and core is 0.05%, and the fiber 4 is alkali-resistant glass fiber, glass fiber, nylon, One or more mixtures of plant fibers, the plant fibers are sawdust, wood chips, and c...

Embodiment 2

[0021] Repeat Example 1, with the following differences: the fiber 4 is a plant fiber, the plant fiber is sawdust, sawdust, plant stem pulverization, the fiber 4 is 0.1% by weight of the core body 2, the Fiber 4 has a length of 10 mm. Plant fibers have the advantages of wide sources and low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com