Fire resistant module and manufacturing method thereof

A manufacturing method and fire-stopping technology are applied in the field of fire safety building materials, which can solve the problems of toxic gas pollution, falling off of fire-resisting module components, a large number of flying fluff and black smoke, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

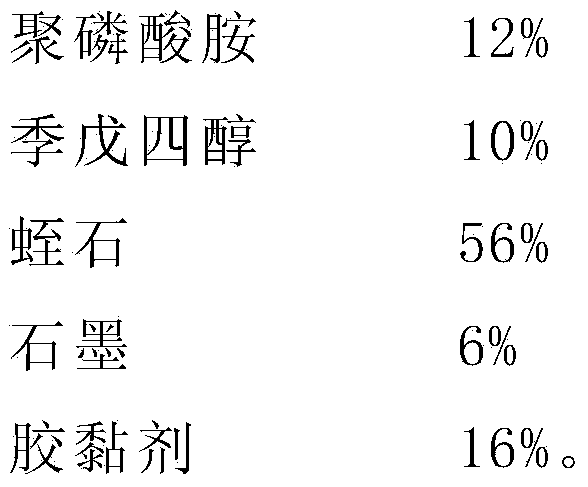

[0037] A fire-retardant module, including a flame retardant, a light expansion agent and an adhesive, the flame retardant is a composition of polyphosphate amine and pentaerythritol, the adhesive is a general-purpose epoxy resin, and the light Mass expansion agent is vermiculite and graphite, and its weight percentage is as follows:

[0038]

Embodiment 2

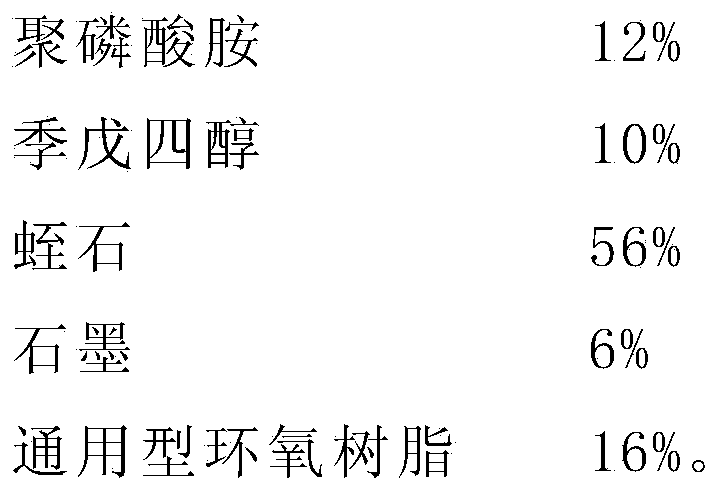

[0040] A fire retardant module, comprising a flame retardant, a light expansion agent and an adhesive, the fire retardant is a composition of polyphosphate amine and pentaerythritol, the light expansion agent is vermiculite and graphite, and the adhesive The agent is a general-purpose epoxy resin, and its weight percentage is as follows:

[0041]

Embodiment 3

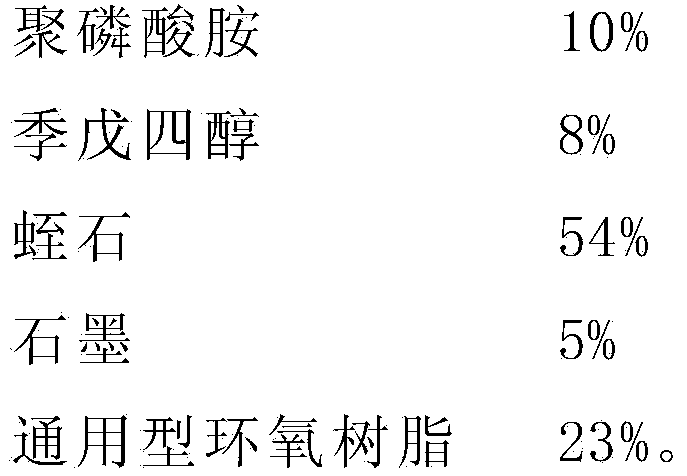

[0043] A fire retardant module, comprising a flame retardant, a light expansion agent and an adhesive, the fire retardant is a composition of polyphosphate amine and pentaerythritol, the light expansion agent is vermiculite and graphite, and the adhesive Agent is phenolic resin, and its percentage by weight is as follows:

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com