A kind of degumming process of fragrant camellia oleifera seed oil

A technology of Camellia oleifera seed oil and Camellia oleifera seed crude oil, which is applied in the field of degumming, can solve the problems of loss of flavor components, low quality of oil products, degumming of oil products, etc., and achieve the goal of improving the effect, avoiding the loss of micronutrient components, and improving the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

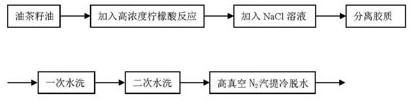

Image

Examples

Embodiment 1

[0030] Put the crude oil of camellia oleifera seed into the degumming tank, add 0.15% of 25Be ° citric acid solution accounting for the total amount of crude oil, first stir rapidly for 5 minutes, then stir at a slow speed of 10 rpm for 118 minutes, then add 10% NaCl solution slowly Stir at high speed for 30 minutes to separate the oil feet in the oil;

[0031] The Camellia oleifera seed oil after separation of the oily residue is washed with water for the first time: add 80°C hot water according to 5% of the crude oil amount and 25Be° citric acid solution accounting for 0.005% of the crude oil amount for rapid mixing for 4 minutes, then slowly Stir at high speed for 10 minutes, oil and water are separated;

[0032] After oil-water separation, the Camellia oleifera seed oil is washed twice: add 4% NaCl solution at 60°C according to 8% of the crude oil, mix quickly for 4 minutes, then stir slowly for 10 minutes, and separate the oil and water;

[0033] The Camellia oleifera se...

Embodiment 2

[0035] Put the crude oil of camellia oleifera seed into the degumming tank, add 0.3% of 25Be ° citric acid solution accounting for the total amount of crude oil, first stir quickly for 10min, then stir slowly at 10rpm for 122min, then add 10% NaCl solution slowly Stir at high speed for 30 minutes to separate the oil feet in the oil;

[0036] The Camellia oleifera seed oil after separation of the oily residue is washed with water for the first time: add 80°C hot water according to 8% of the crude oil amount and 25Be° citric acid solution accounting for 0.02% of the crude oil amount for rapid mixing for 6 minutes, then slowly Stir at high speed for 15 minutes, oil and water are separated;

[0037] After the oil-water separation, the Camellia oleifera seed oil is washed twice: add 6% NaCl solution at 60°C according to 10% of the crude oil, mix quickly for 6 minutes, then stir slowly for 15 minutes, and separate the oil and water;

[0038] The Camellia oleifera seed oil after the...

Embodiment 3

[0040] Pour the fragrant camellia seed crude oil into the degumming tank, add 0.2% of 25Be° citric acid solution accounting for the total amount of the crude oil, first stir rapidly for 8 minutes, then stir at a slow speed of 10 rpm for 120 minutes, then add 10% NaCl solution slowly Stir at high speed for 30 minutes to separate the oil feet in the oil;

[0041] The Camellia oleifera seed oil after separation of the oily residue is washed with water for the first time: add 80°C hot water according to 6% of the crude oil amount and 25Be° citric acid solution accounting for 0.01% of the crude oil amount for rapid mixing for 5 minutes, then slowly Stir at high speed for 12 minutes, oil and water are separated;

[0042] After the oil-water separation, the Camellia oleifera seed oil is washed twice: add 5% NaCl solution at 60°C according to 9% of the crude oil amount, mix quickly for 5 minutes, then stir slowly for 12 minutes, and separate the oil and water;

[0043] The Camellia o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com