Device for improving low-temperature reduction degradation indexes of sintered ores and utilization method of device

A sinter, low temperature technology, applied in the direction of improving process efficiency, to achieve the effect of reducing dosage, improving low temperature reduction and pulverization index, and reducing blast furnace equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

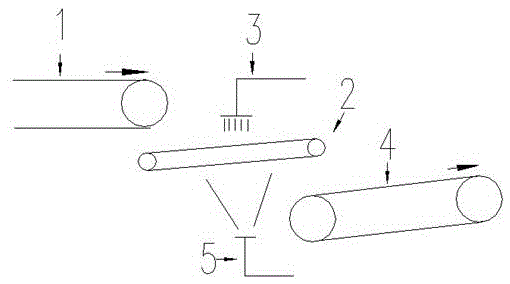

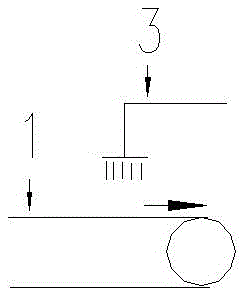

[0022] Depend on figure 2 It can be seen from the structure of the prior art shown that the existing method of spraying the sinter low-temperature reduction pulverization inhibitor is to directly spray the low-temperature reduction pulverization inhibitor solution on the belt. The amount of spraying is small and can only cover the surface layer of sinter. It is difficult to cover the lower layer and the cavity of the sintered ore with the low-temperature reduction pulverization inhibitor solution, which makes the effect poor. The present invention is based on a new discovery. It is found through experimental research that the improvement of the pulverization index of sintered ore at low temperature reduction is closely related to the coverage degree of the spraying inhibitor solution, but not very closely related to the spraying concentration within a certain range. In the online belt spraying method, if the amount of spraying is small, the coverage will be uneven and the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com