Cement-based material underwater grouting or mud-jack rock block foundation construction method

A cement-based material and foundation construction technology, applied in infrastructure engineering, sustainable waste treatment, solid waste management, etc., can solve problems such as hindering construction, affecting farming, affecting reservoir water storage, etc. The effect of construction progress and reduction of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

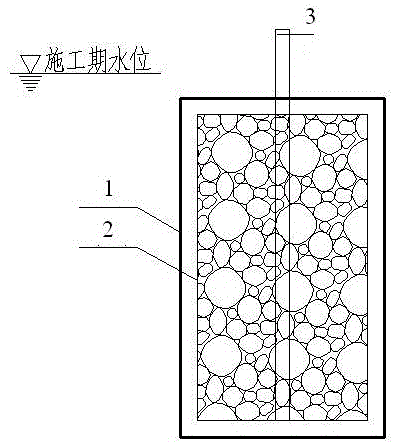

[0068] Include the following steps:

[0069] (1) Use the hook machine to excavate the foundation groove, and the length of a single operation is 2.5 to 3.5 meters;

[0070] (2) According to the condition of the foundation tank, choose the cement-based material underwater grouting method or grouting stone method for foundation construction:

[0071] (1) When the excavated foundation groove is located under the water surface, the closed structure shaping cage is used, and the cement-based material underwater grouting method is selected for foundation construction:

[0072] The closed structure shaped cage can be made underwater or on land and then put into the water. Steel bars, geogrids or wooden strips are used to weave the gabion with steel wires. Wrap or line with non-woven fabric. The function of non-woven fabric is to drain the water in the gabion and prevent the cementitious material in the gabion from leaking out. Insert a grouting pipe into the gabion so that the grout...

Embodiment 2

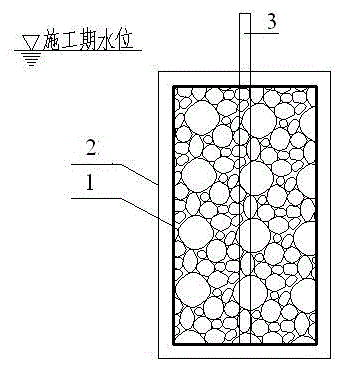

[0115] Include the following steps:

[0116] (1) Use the hook machine to excavate the foundation groove, and the length of a single operation is 2.5 to 3.5 meters;

[0117] (2) According to the condition of the foundation tank, choose the cement-based material underwater grouting method or grouting stone method for foundation construction:

[0118] (1) When the excavated foundation groove is located under the water surface, the closed structure shaping cage is used, and the cement-based material underwater grouting method is selected for foundation construction:

[0119] The closed structure shaped cage can be made underwater or on land and then put into the water. Steel bars, geogrids or wooden strips are used to weave the gabion with steel wires. Wrap or line with non-woven fabric. The function of non-woven fabric is to drain the water in the gabion and prevent the cementitious material in the gabion from leaking out. Insert a grouting pipe into the gabion so that the grout...

Embodiment 3

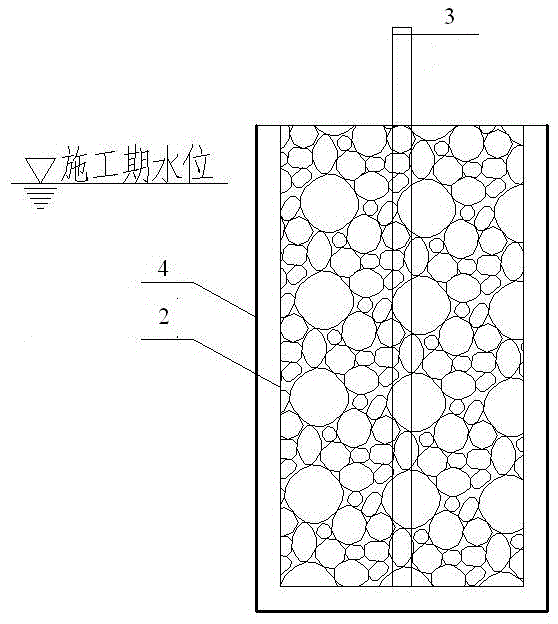

[0166] Include the following steps:

[0167] (1) Use the hook machine to excavate the foundation groove, and the length of a single operation is 2.5 to 3.5 meters;

[0168] (2) According to the condition of the foundation tank, choose the cement-based material underwater grouting method or grouting stone method for foundation construction:

[0169] (1) When the excavated foundation groove is located under the water surface, the closed structure shaping cage is used, and the cement-based material underwater grouting method is selected for foundation construction:

[0170] The closed structure shaped cage can be made underwater or on land and then put into the water. Steel bars, geogrids or wooden strips are used to weave the gabion with steel wires. Wrap or line with non-woven fabric. The function of non-woven fabric is to drain the water in the gabion and prevent the cementitious material in the gabion from leaking out. Insert a grouting pipe into the gabion so that the grout...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com