Method for reducing emission and oil consumption of engine by using tail gas waste heat

An engine and exhaust technology, applied in the direction of engine lubrication, engine components, combustion engines, etc., can solve the problems of poor lubrication effect of internal combustion engines, short walking distance, large time ratio, etc., to improve the quality of urban environment and simple operation. , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is described in further detail:

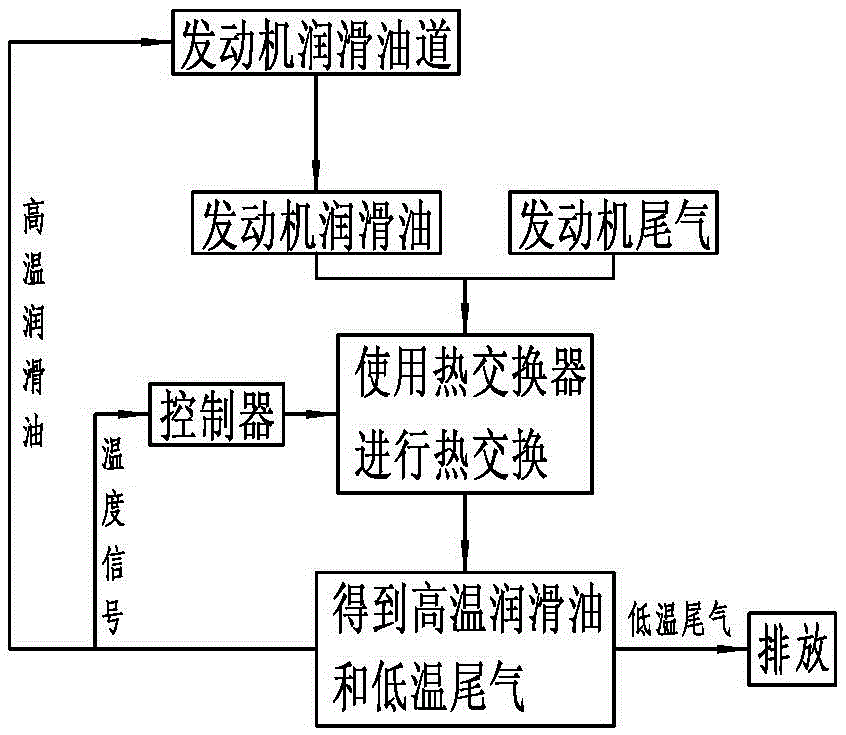

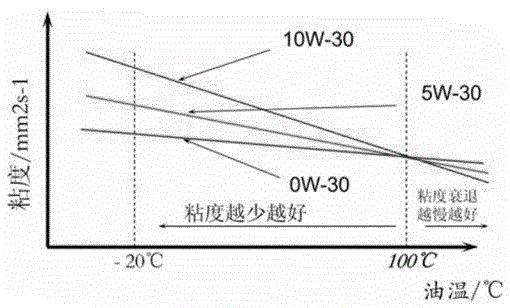

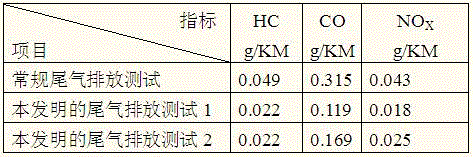

[0016] The invention uses exhaust gas discharged from the engine to heat the lubricating oil of the engine, so that the lubricating oil of the engine reaches the set ideal lubricating working temperature as soon as possible and maintains the ideal lubricating working temperature. Such as figure 1 As shown, the steps of the method for reducing engine oil consumption by using exhaust waste heat in the embodiment of the present invention are as follows: After the engine exhaust gas and the engine lubricating oil drawn from the engine lubricating passage are introduced into the heat exchanger for heat exchange, low-temperature exhaust gas and high-temperature lubricating oil are obtained. , introduce high-temperature lubricating oil into the engine slideway as a lubricating medium for recycling, and discharge low-temperature exhaust gas at the same time; in the process of heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com