Insulation board for heat insulation and cold preservation of liquefied gas cryogenic storage tank

A low-temperature storage tank and liquefied gas technology, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, tank/barrel/barrel, etc. The problem of tightness and insufficient strength of the insulation board has achieved the effect of wide application range, good airtight performance and excellent airtight performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

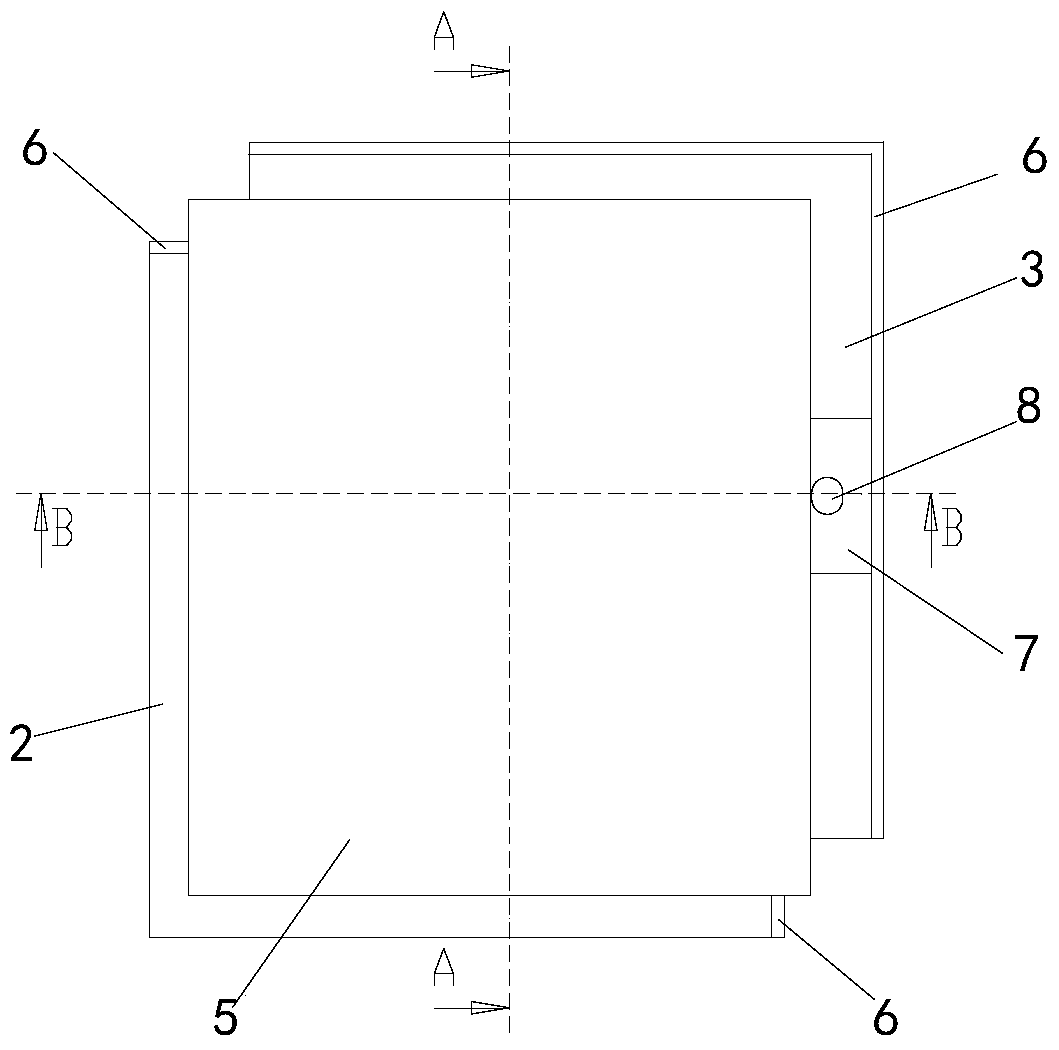

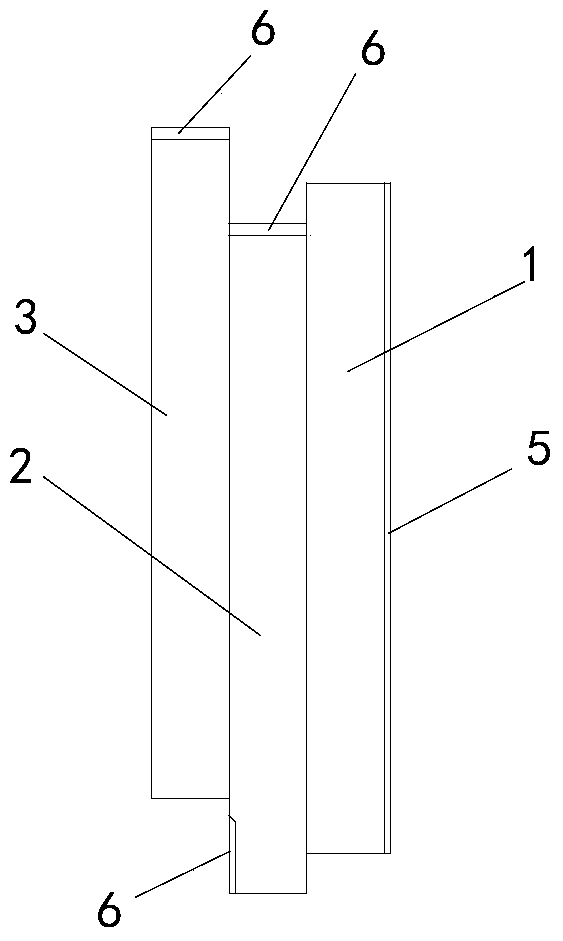

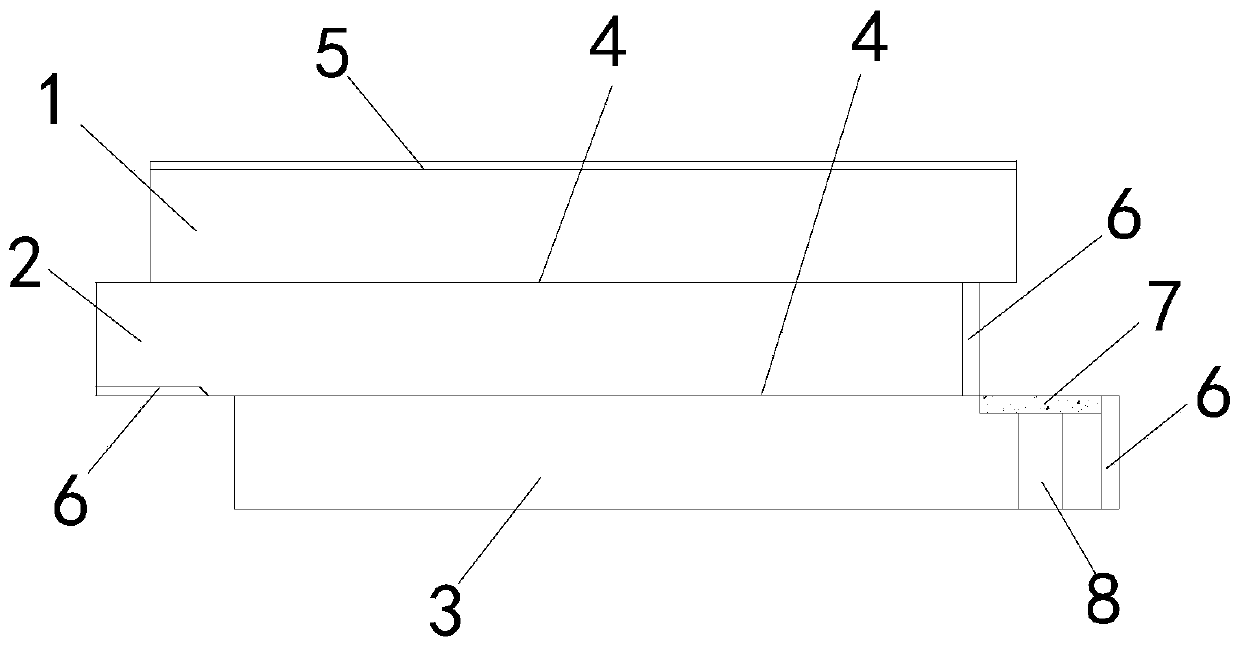

[0025] see figure 1 , with reference to figure 2 , image 3 , the thermal insulation board used for heat insulation and cold preservation of liquefied gas cryogenic storage tanks of the present invention includes a first thermal insulation layer 1, a second thermal insulation layer 2 and a third thermal insulation layer 3 arranged in sequence, and the three layers of thermal insulation layers are misplaced, and in four The sides all form a mortise joint structure, and the adjacent insulation layers are bonded and connected by low-temperature glue 4 , and an outer protective layer 5 is provided on the upper surface of the first insulation layer.

[0026] The insulation material of each insulation layer in the present invention is selected from one or more of rigid polystyrene foamed plastics, rigid polyurethane foamed plastics, and phenolic foamed plastics, and is reinforced with glass fibers.

[0027] The outer protective layer 5 in the present invention is made of metal or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com