Flexible stab-resistant material arranged without gaps and preparation method of flexible stab-resistant material

A gapless and flexible technology, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of low weaving efficiency of three-dimensional looms, flow of shear thickening fluid, and difficulty in maintaining protective bodies. Achieve the effects of shortening the time for arranging and loading small protective modules, improving processing efficiency, and good protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

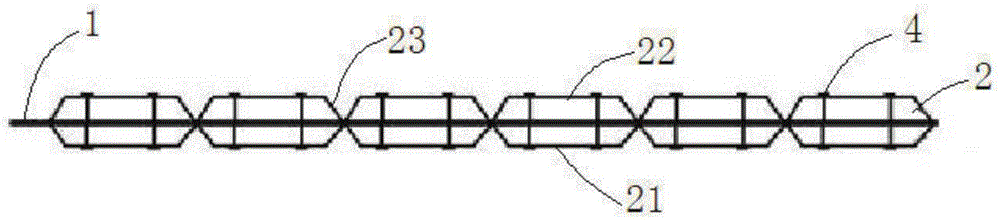

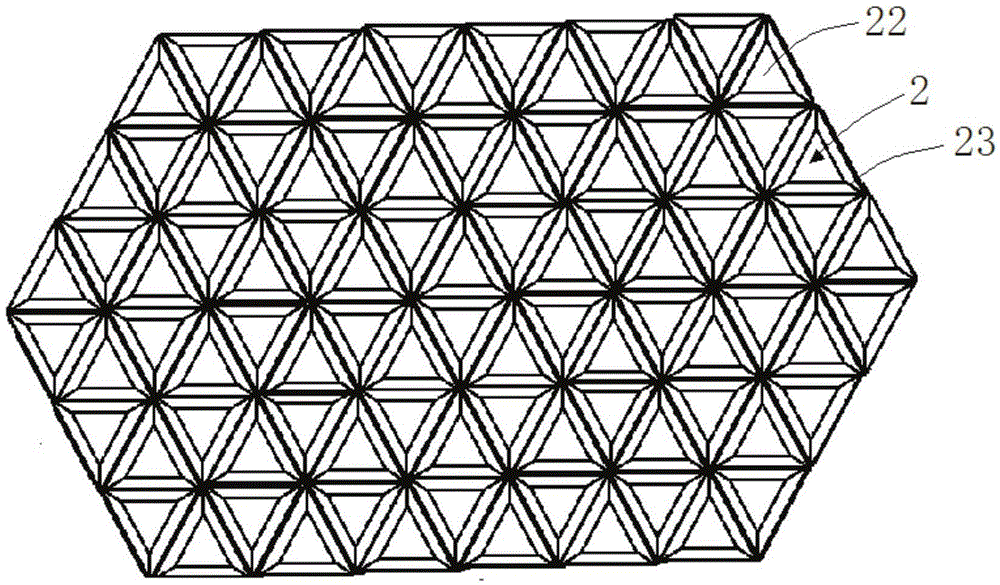

[0040] like Figure 4 , the present invention also discloses a preparation method of a flexible anti-stab material arranged without gaps. The flexible anti-stab material arranged without gaps is composed of a flexible fabric 1 and several small protective modules 2 arranged on both sides of the flexible fabric. The fabric 1 and the small protective modules 2 on both sides are fixedly connected by an arrangement without gaps. The specific preparation method includes the following preparation steps:

[0041] S1, prepare the small protective module, and make the small protective module by injection molding or machining according to the preset parameters of the small protective module;

[0042] Among them, the small protective module made of thermoplastic reinforced composite material is made by injection molding; the small protective module made of metal is made by mechanical processing. The preset parameters of the small protective module include the shape, size and thickness of ...

Embodiment 1

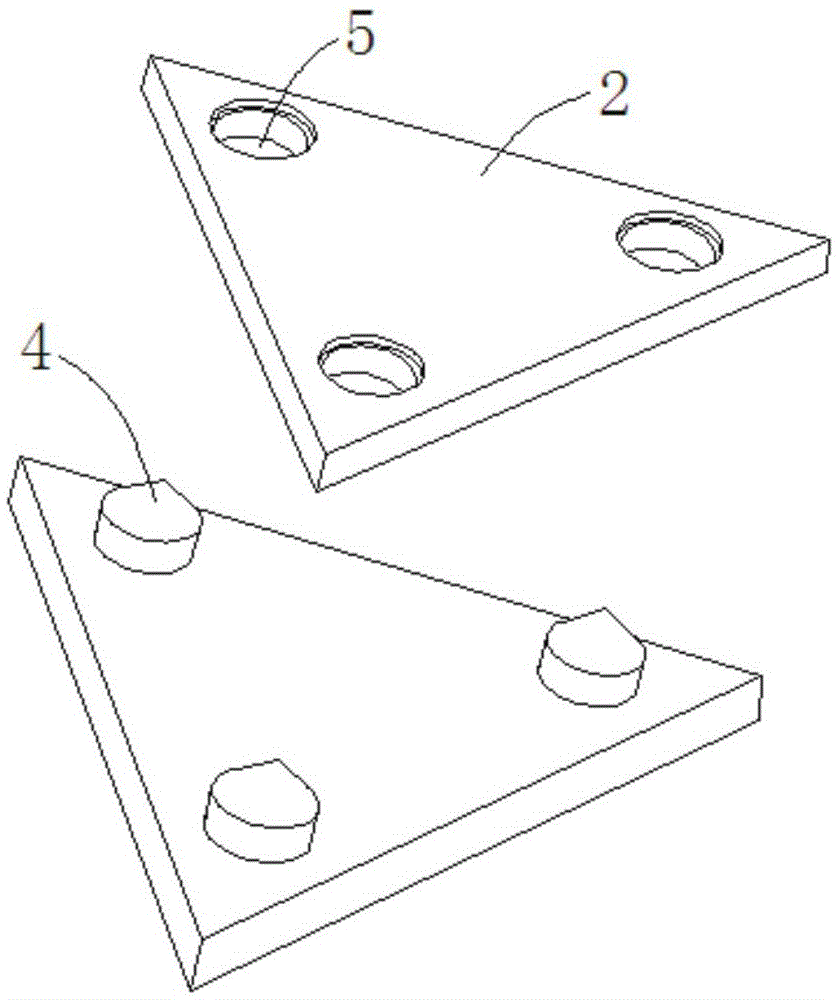

[0051] In the flexible anti-stab material, the small protective module is made of carbon fiber staple fiber and thermoplastic nylon 66 composite reinforcement material through injection molding process, the mass fraction ratio of carbon fiber short fiber and nylon material is 1:3, and the side length of the small protective module is It is an equilateral triangle of 15mm, the thickness is 1.5mm, and the slope of the small protective module is 8°. as attached Figure 5 , 6 The lower mold has three rivets for riveting, and the small protective module of the upper mold has three through holes at the riveting position, and there are bayonet holes on the through holes. Figure 4 After the assembly is completed, the protruding rivets are flattened to the bayonet by heat welding to fix them firmly.

[0052] The flexible fabric sandwiched between the small protective modules is plain fabric made of aramid yarn, the weight of the fabric is 200 grams per square meter, and the gap betw...

Embodiment 2

[0055] In the flexible anti-stab material, the protective small module material that forms the protective material layer is made of high-strength aluminum alloy material, and the small protective module is made by machining. The specific size is a square with a side length of 20mm, a thickness of 1.5mm, and a thickness of The slope in the direction is 10°, such as image 3 After the two sides of the flexible fabric are aligned and overlapped, such as figure 1 Fastened by rivets. The flexible stab-proof fabric sandwiched in the middle can adopt the fabric made of nylon filament, and the fabric gram weight is 200 grams per square meter.

[0056] The quantity of the flexible protective material thus made is 1 protective layer, and the total mass of the protective layer of the cut-resistant clothing is 1.3kg, which can effectively protect against cutting and cutting injuries from sharp objects such as knives and glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com