Method and apparatus for determining measurement mode and tolerance of optical system parameters

A measurement mode and optical system technology, applied in the field of optical measurement, can solve problems such as difficult to meet the requirements of high sensitivity and precision measurement, and achieve the effect of suppressing measurement noise and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

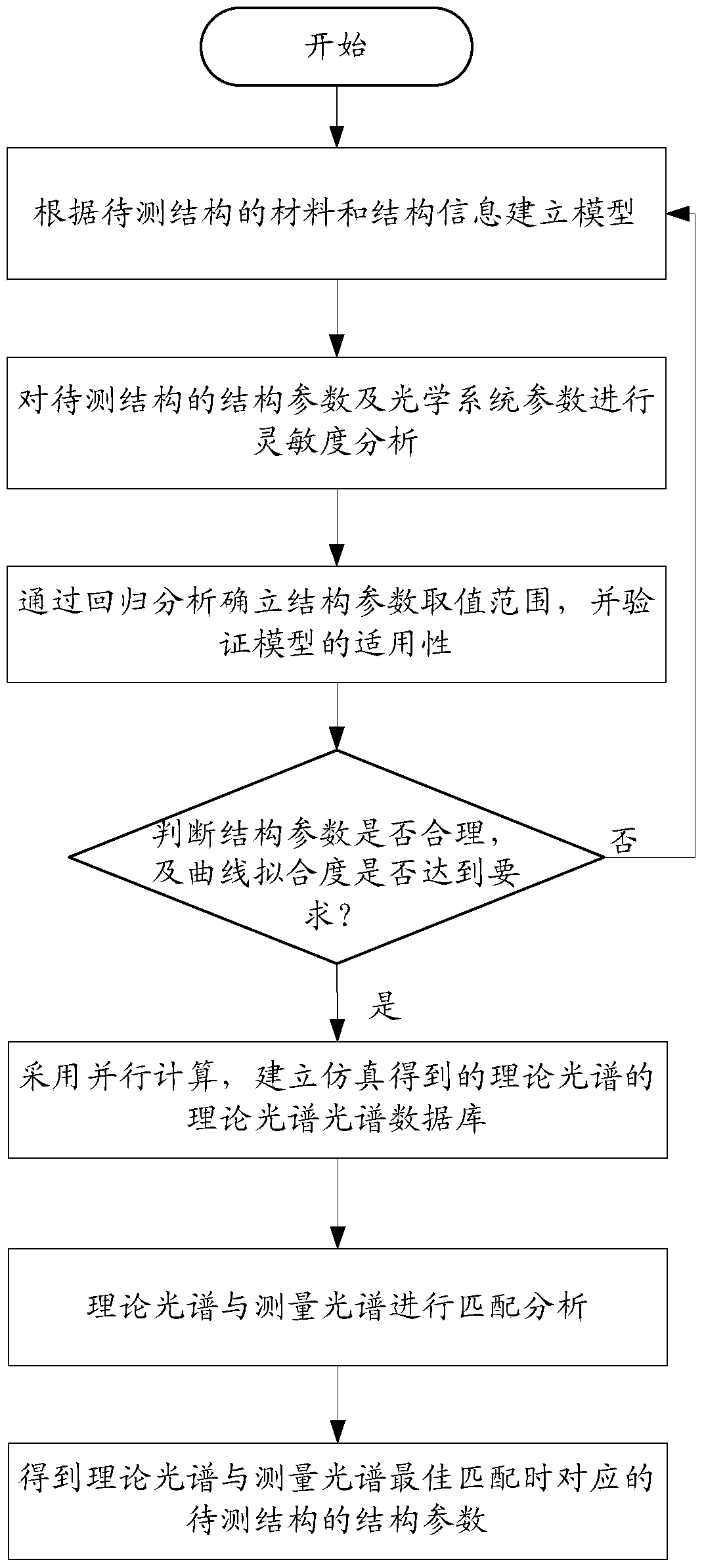

[0023] In order to illustrate the solution of the present invention more clearly, the OCD measurement principle is first described below:

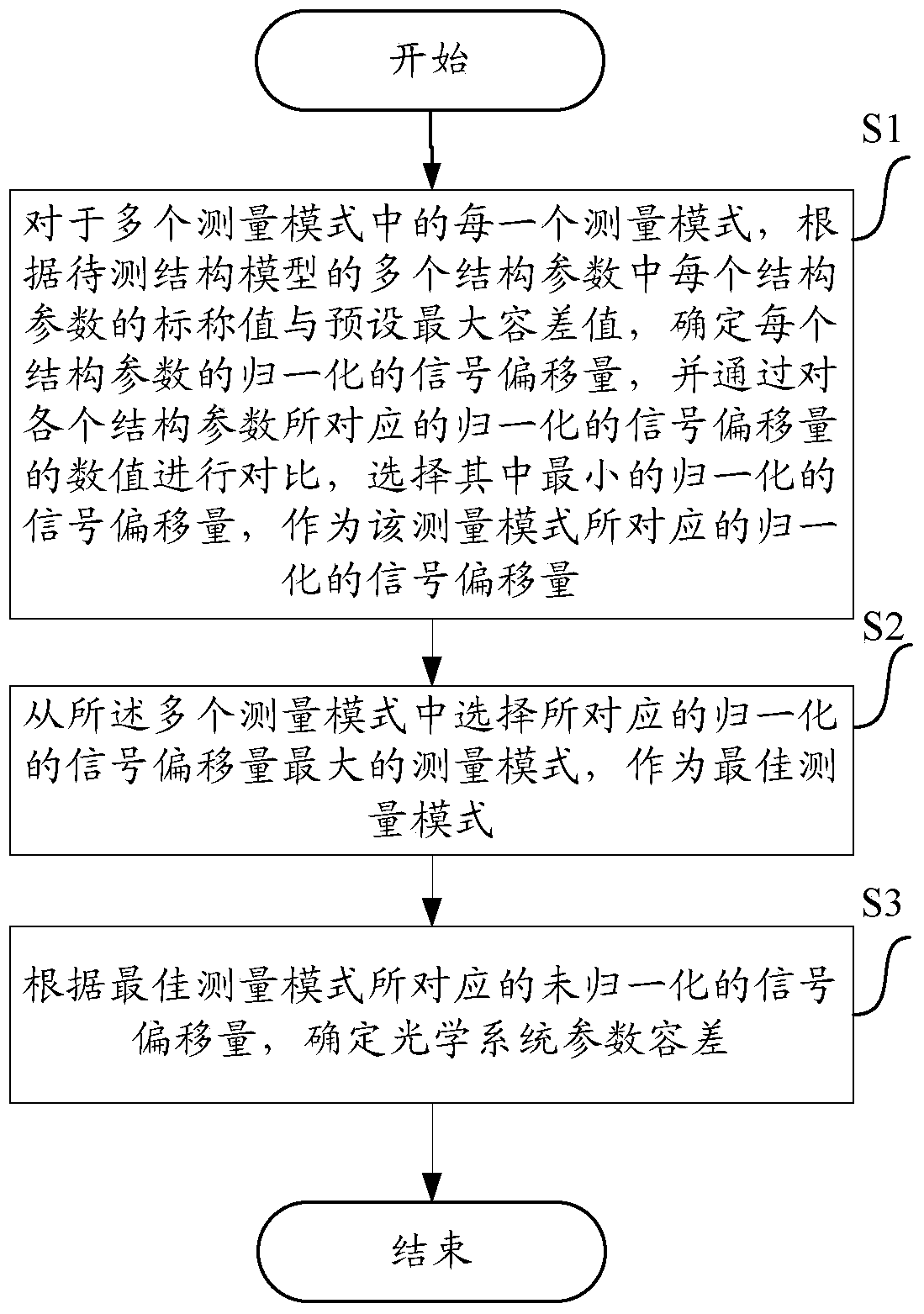

[0024] The implementation steps of the OCD measurement principle may include:

[0025] 1) The OCD measurement equipment establishes a theoretical spectral database corresponding to the morphology of the structure to be measured.

[0026] The specific implementation of this step includes: first, the OCD measurement device establishes the structure model to be measured according to the shape of the structure to be measured; then, the OCD measurement device performs theoretical simulation on the structure model to be measured according to the selected measurement mode and optical system parameters , to obtain the corresponding theoretical spectrum of the structure to be measured; then, the OCD measuring device establishes a theoretical spectrum database of the structure to be measured according to the theoretical spectrum of the structure to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com