Characterization method for hardness of electrode materials under combined action of electrochemistry and substrate effects

A technology of electrode material and substrate effect, which is applied in the field of research on the characterization of mechanical properties of energy materials, and can solve problems such as characterization methods that do not comprehensively consider hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

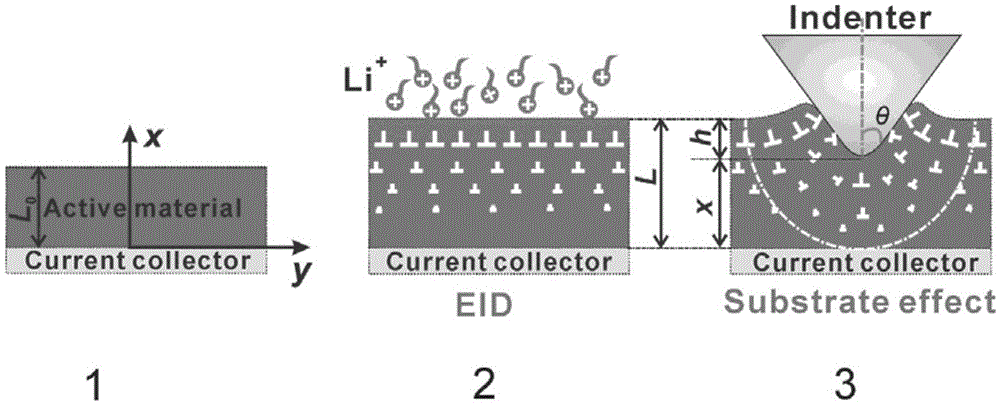

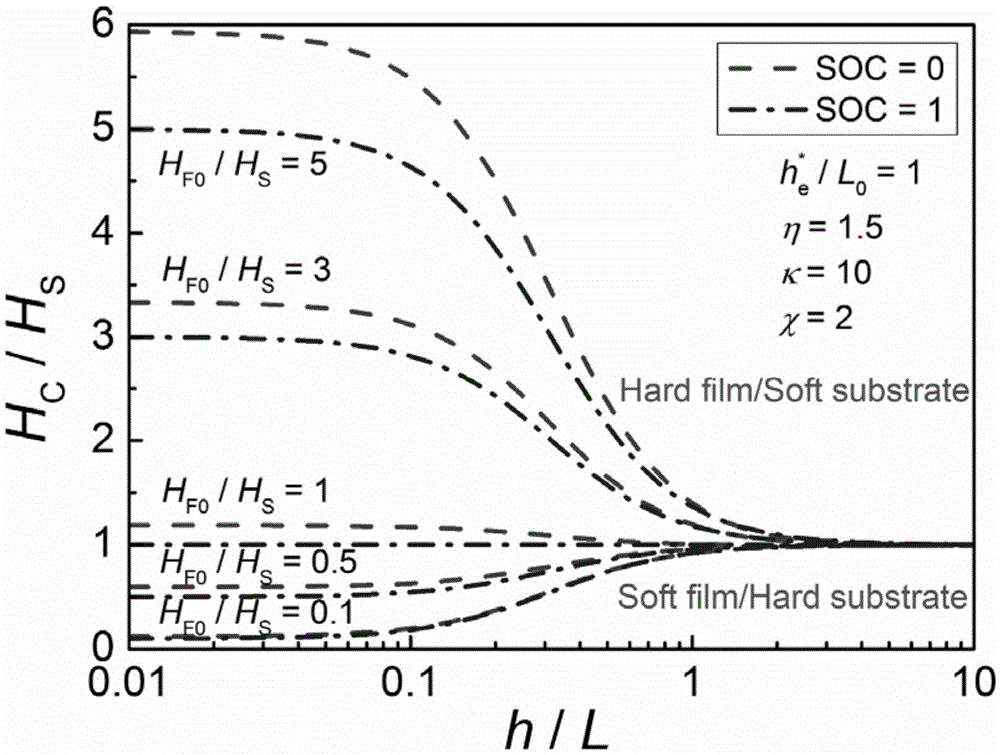

Method used

Image

Examples

Embodiment 1

[0037] The specific implementation steps are as follows:

[0038] The first step is to determine the concentration distribution of lithium ions inside the electrode material by solving the diffusion equation:

[0039] Based on two-dimensional thin film electrode materials, the maximum lithium ion concentration c 0 And the diffusion coefficient D is assumed to be a constant, which does not change with the change of the charging and discharging process, and L is the film thickness at time t. Thus, the lithium ion concentration distribution of the two-dimensional thin film material in a certain state can be obtained as:

[0040] c = c 0 [ 1 - Σ n = 0 ∞ 4 ( - 1 ) ...

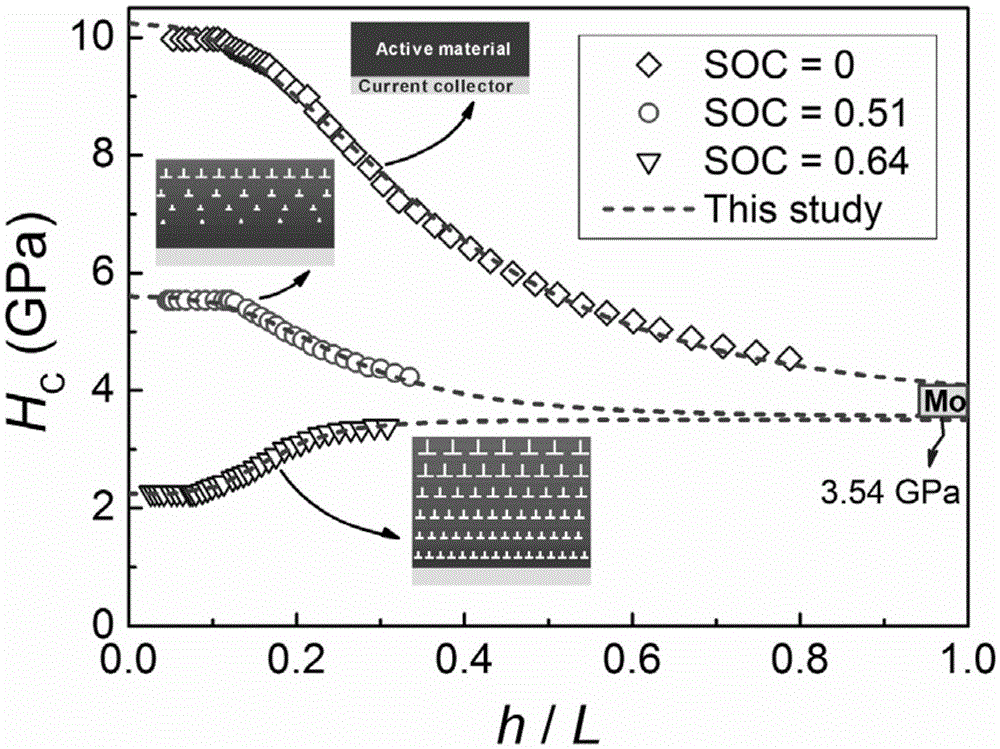

Embodiment 2

[0051] The specific implementation steps are as follows:

[0052] The first step is the selection of Si negative electrode material for lithium ion battery

[0053] A Si film with a thickness of 1.4 μm was prepared by magnetron sputtering [L.A.Berla, S.W.Lee, Y.CuiandW.D.Nix, J.PowerSources, 2015, 273, 41-51], and then assembled into a button Batteries, through the method of constant current control to obtain Si negative electrode materials with different electric quantities.

[0054] The second step is to conduct indentation experiments on Si anode materials under different charge and discharge states

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com