spring operating mechanism for gis circuit breaker

An operating mechanism and circuit breaker technology, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of expensive spring mechanisms, high technological level requirements, unstable technical parameters, etc., and achieves compact structure and reasonable utilization. The effect of stable space and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

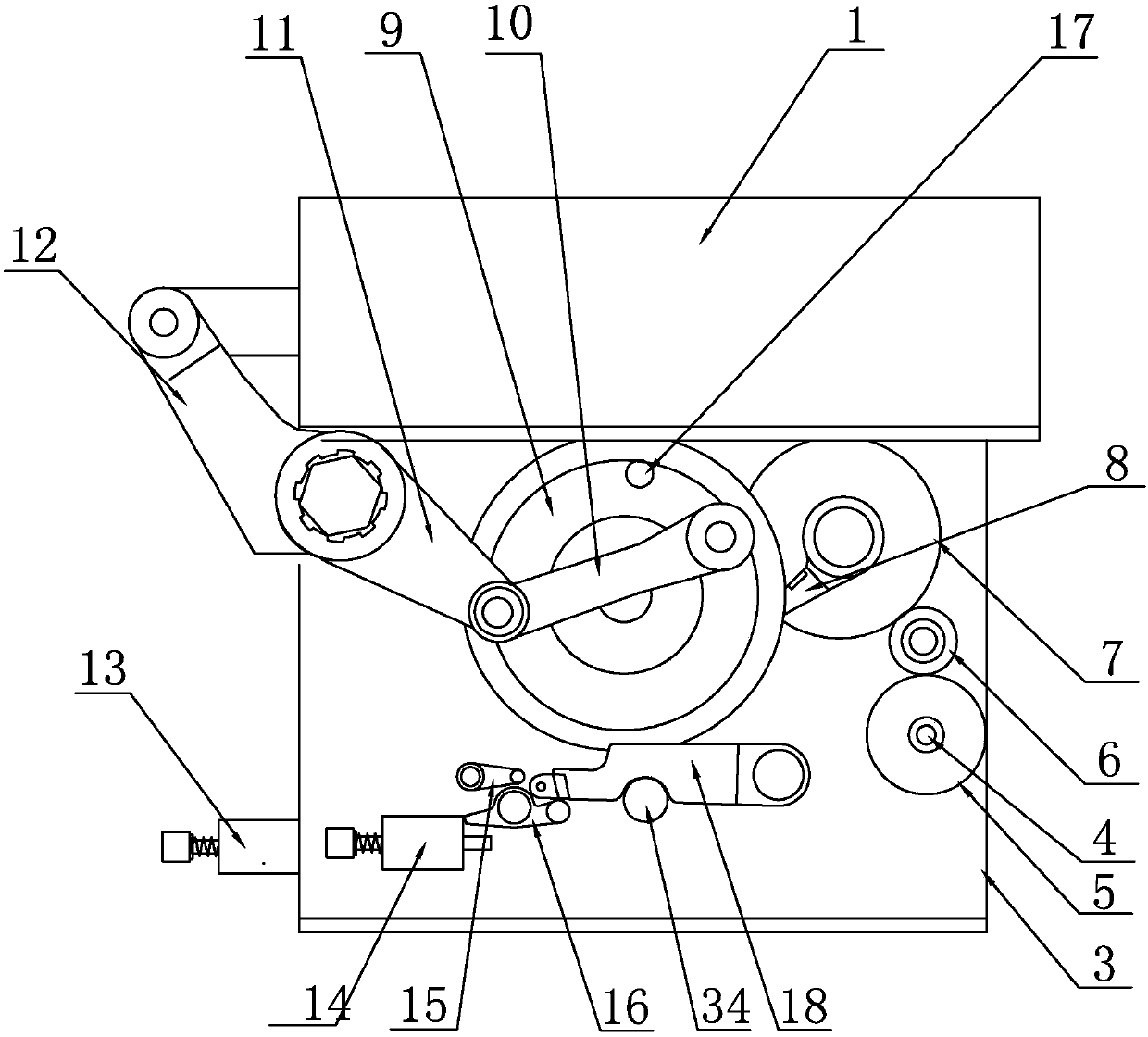

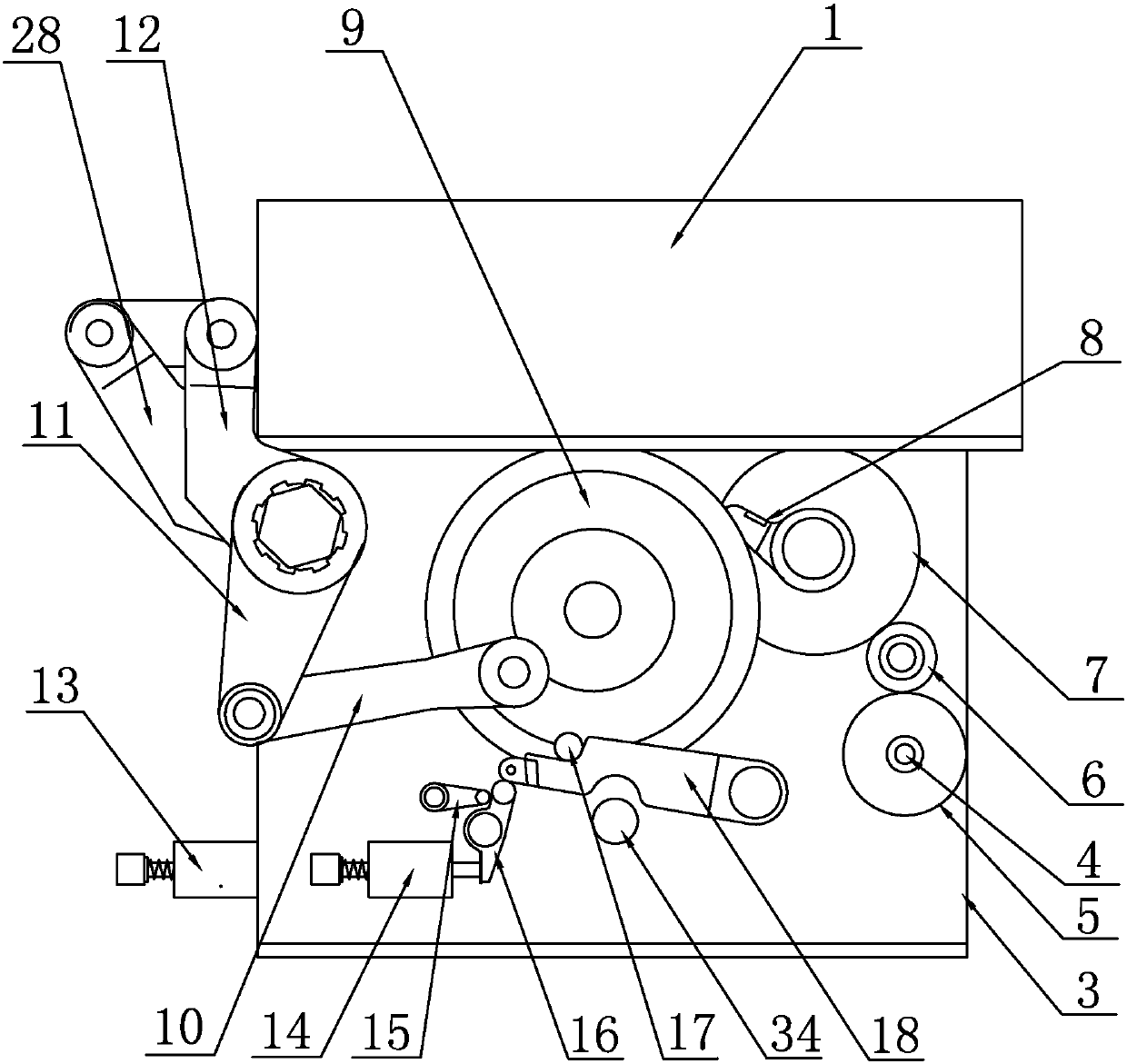

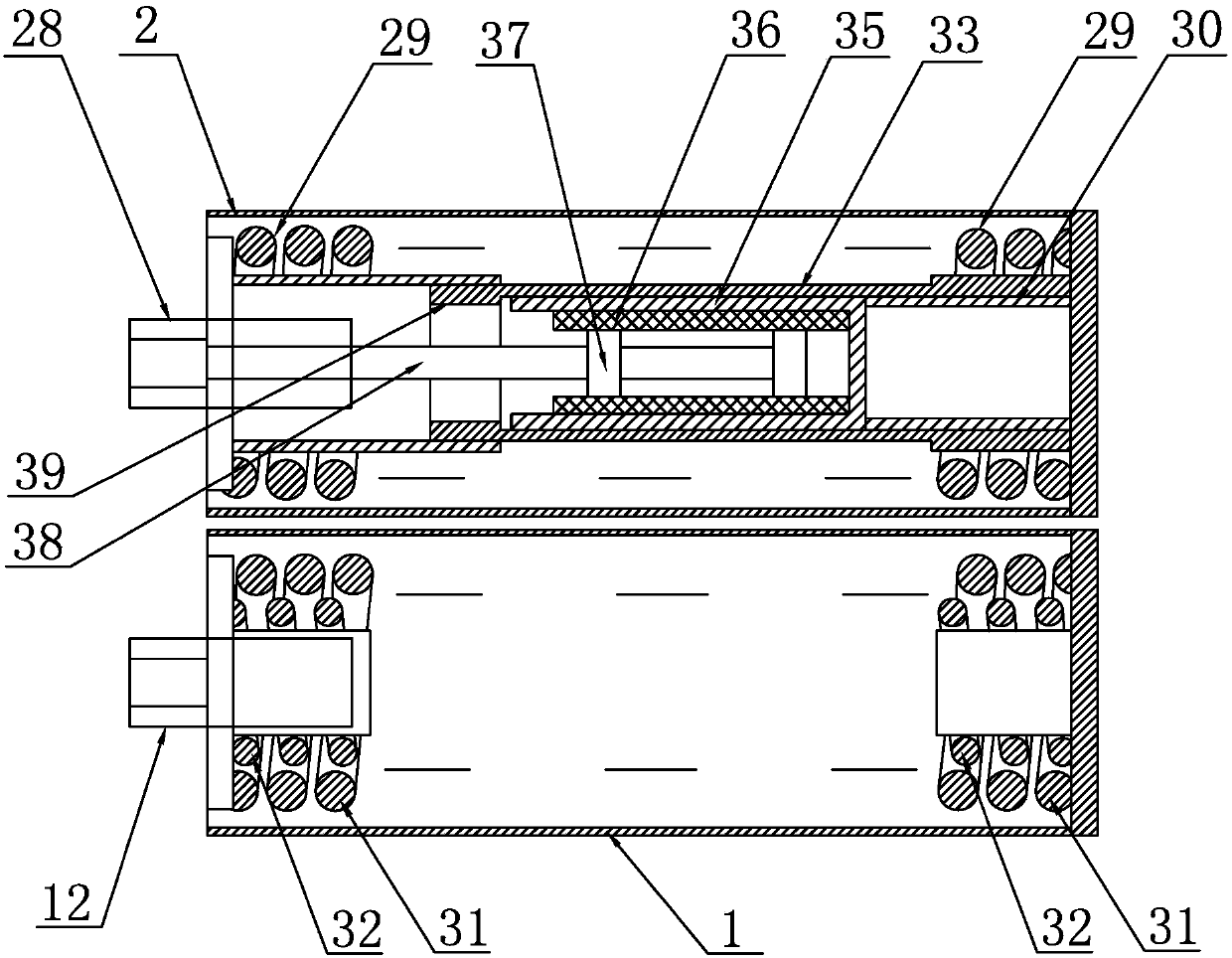

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5Shown is a spring operating mechanism for a GIS circuit breaker of the present invention, including a first spring barrel 1, a second spring barrel 2, and a double-sided splint 3, and the distance between the two splints in the double-sided splint 3 is 100 mm. The first spring barrel 1 and the second spring barrel 2 are cylindrical structures arranged side by side in the horizontal direction. The front ends of the first spring barrel 1 and the second spring barrel 2 are open, and the inside of the first spring barrel 1 is The extension direction of the first closing spring 31 and the second closing spring 32 are provided, the diameter of the first closing spring 31 is larger than the diameter of the second closing spring 32, and the second closing spring 32 is sleeved on the first closing spring. Inside the spring 31, the rear ends of the first closing spring 31 and the second closing spring 32 are conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com