Double-glass light transmission assembly

A technology of light-transmitting components and battery components, applied in the field of photovoltaics, can solve the problems of uneven visible area of components, high investment cost, large series resistance, etc., and achieve the effects of saving materials, increasing light transmittance, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

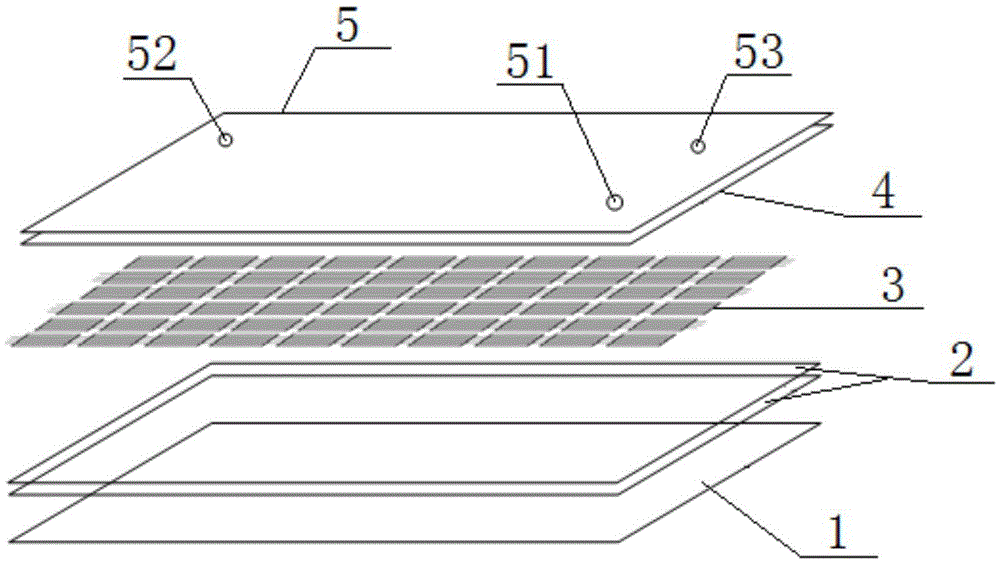

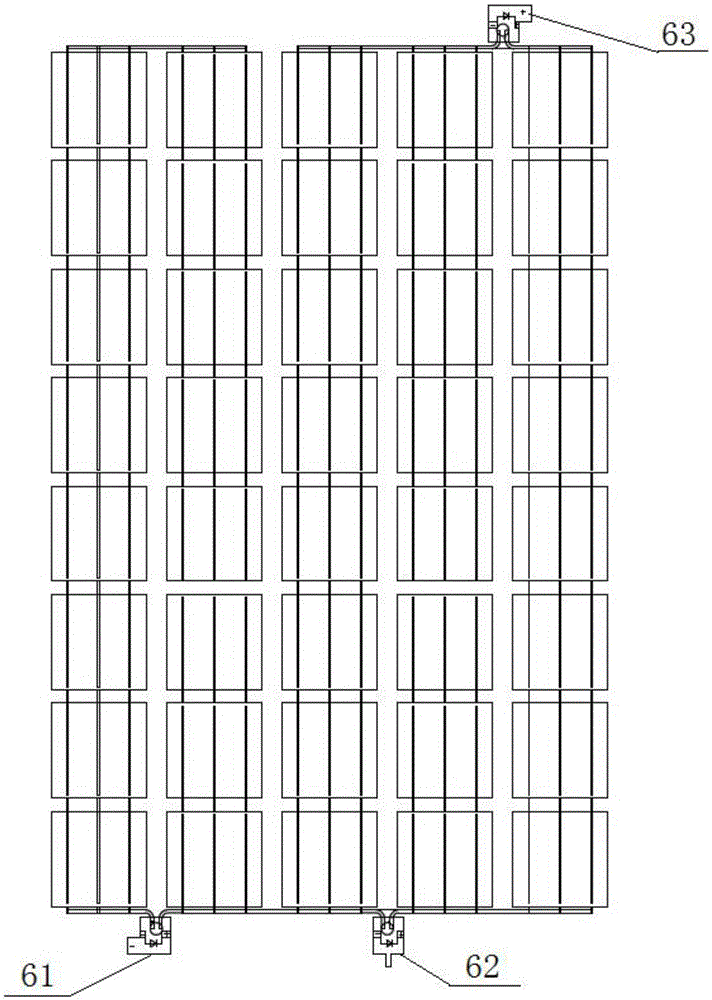

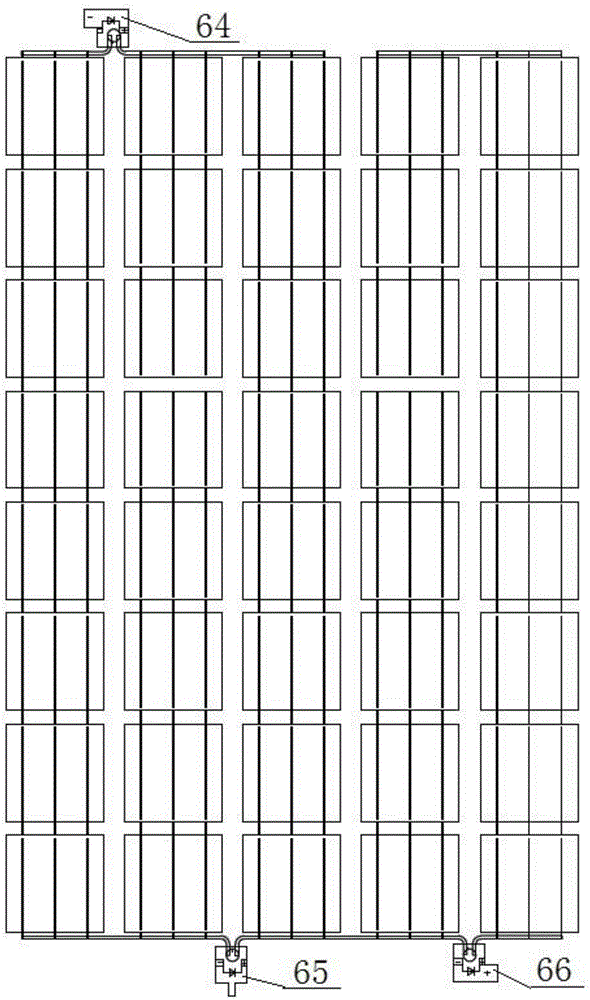

[0025] Such as Figure 1-Figure 3 As shown, the present invention discloses a double-glass light-transmitting assembly, which includes a front panel embossed coated tempered glass 1, a first packaging layer 2, a battery assembly 3, a second packaging layer 4 and a back panel light-transmitting tempered glass Glass 5, the battery assembly 3 is composed of several battery strings and split junction boxes, several battery strings are connected with the split junction box, the battery assembly 3 is arranged between the first packaging layer 2 and the second packaging layer 4, and the split wiring The box is glued on the back plate light-transmitting tempered glass 5, and the back plate light-transmitting tempered glass 5 is provided with at least a positive electrode outlet hole 51 and a negative electrode outlet hole 52, and the battery strings are odd-numbered strings. Such as figure 1 As shown, taking the bottom as the top, the first encapsulation layer 2 is disposed under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com