Cobalt-free alloy material powder metallurgy valve seat and its preparation method and application

A powder metallurgy and valve seat technology, applied in the field of metallurgy, can solve the problems of high price, far-fetched, large impact force of the valve, etc., and achieve the effect of practical wear-resistant material, low price and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

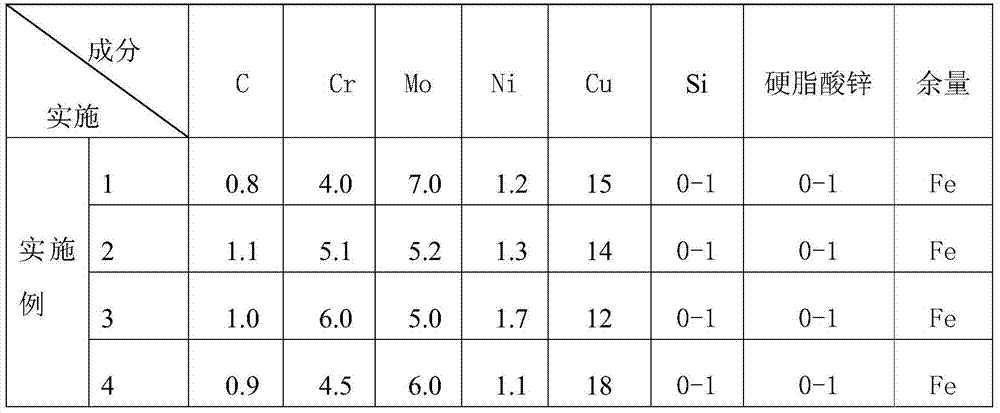

[0025] The following are the elemental compositions and mass percentages of the four specific examples, as shown in Table 1.

[0026] Table 1

[0027]

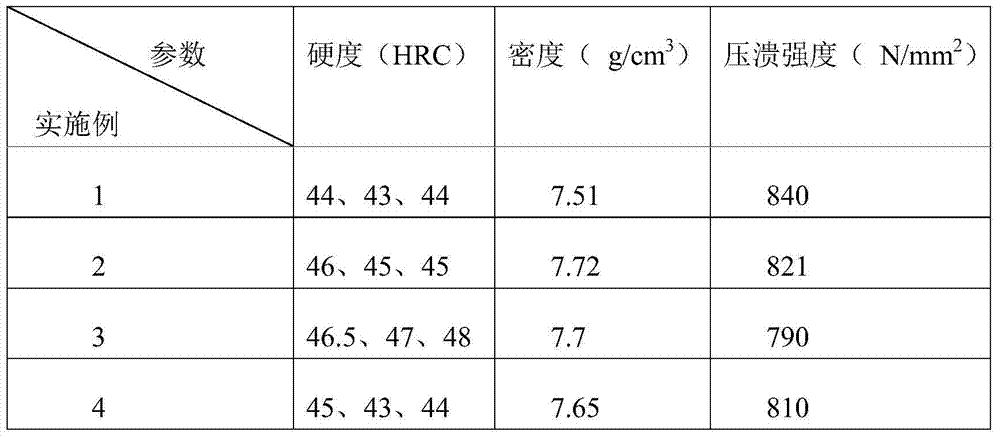

[0028] The detection data of the valve seat in the four embodiments are shown in Table 2.

[0029] Table 2

[0030]

[0031] According to the reliability test specifications, the valve seat products of the above examples 2 and 4 were run on the test bench at full speed and full load (rated speed 2300 rpm, power 206kw, maximum torque 960N.m) for a total of 800 hours, and the valve seats were made of cobalt-free materials. The wear amount is 0.038mm, while the QZ5 cast iron valve seat wear amount is 0.047mm, which meets the design requirements. Then we sent 200 sets to a diesel engine cylinder head factory for trial use, and no early wear has been found for 5 months so far.

[0032] In summary, the implementation results show that the cobalt-free material valve seat of the present invention has excellent wear resistance,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com