Thermoelectric conversion system and monitoring method for maintaining engine heat and back pressure balance

A thermoelectric conversion and engine technology, applied in engine cooling, engine components, combustion engines, etc., can solve the problems of increasing exhaust back pressure, energy waste, and low overall system efficiency, reducing cold end temperature and realizing back pressure. balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

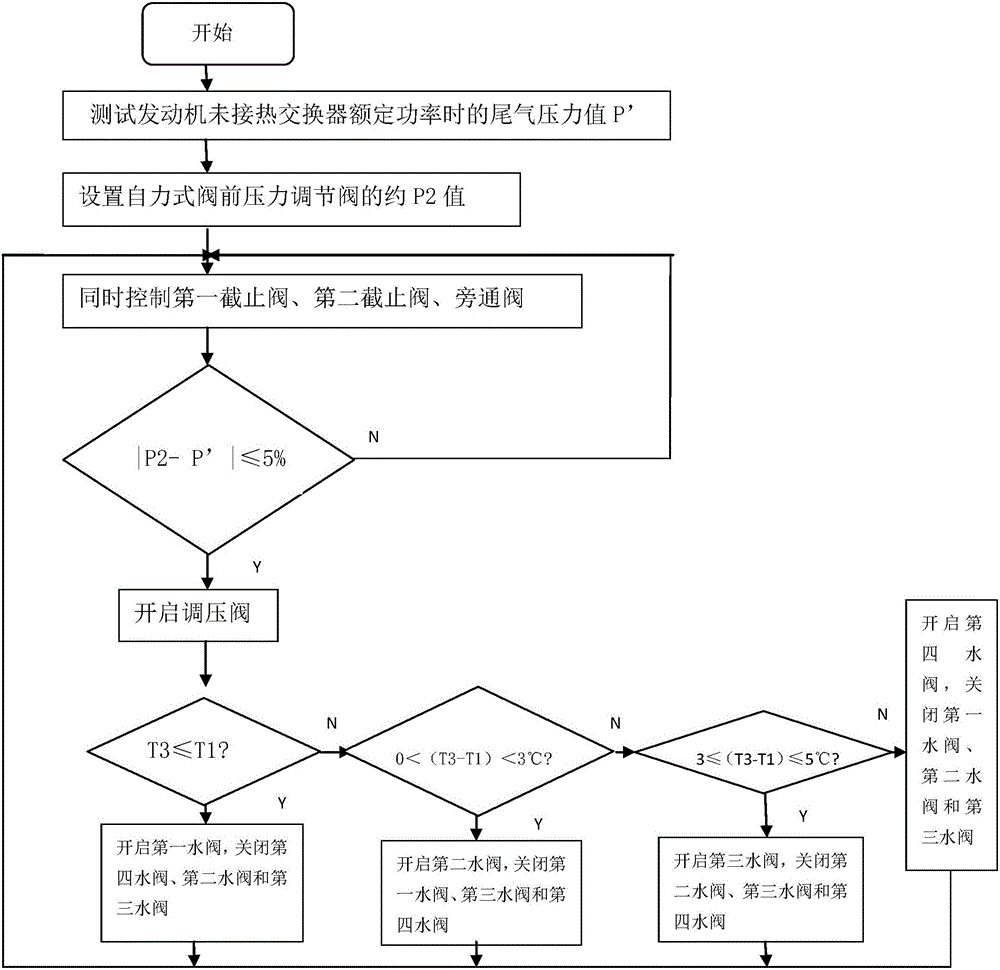

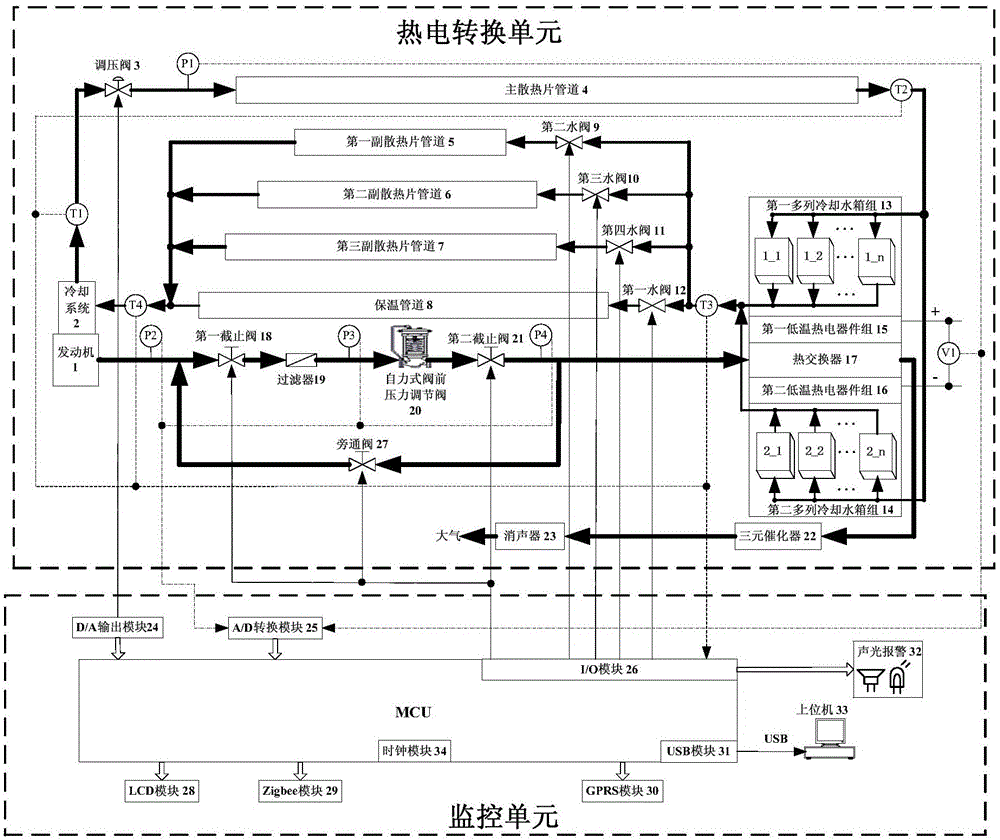

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as figure 1 Shown is the exhaust gas thermoelectric conversion system that maintains the balance of engine heat and back pressure, including the thermoelectric conversion unit and the monitoring unit.

[0029] In this embodiment, three sub-radiating fin pipelines are used, namely the first sub-radiating fin pipeline 5, the second sub-radiating fin pipeline 6, and the third sub-radiating fin pipeline 7, and the length of the first sub-radiating fin pipeline 5 is less than The length of the second sub-radiating fin pipeline 6, the length of the second sub-radiating fin pipeline 6 is less than the length of the third sub-radiating fin pipeline 7, and metal cooling fins with high-efficiency heat dissipation performance are installed around each cooling fin pipeline.

[0030] The thermoelectric conversion unit includes an engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com