Microhole plate sound absorption grating

A microporous plate and sound absorption technology is applied in the field of noise reduction of range hoods, which can solve the problems of small thickness of sound-absorbing materials, reduced sound-absorbing performance, and poor sound-absorbing effect of sound-absorbing cotton, so as to achieve good sound-absorbing performance, Easy to install and remove for cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

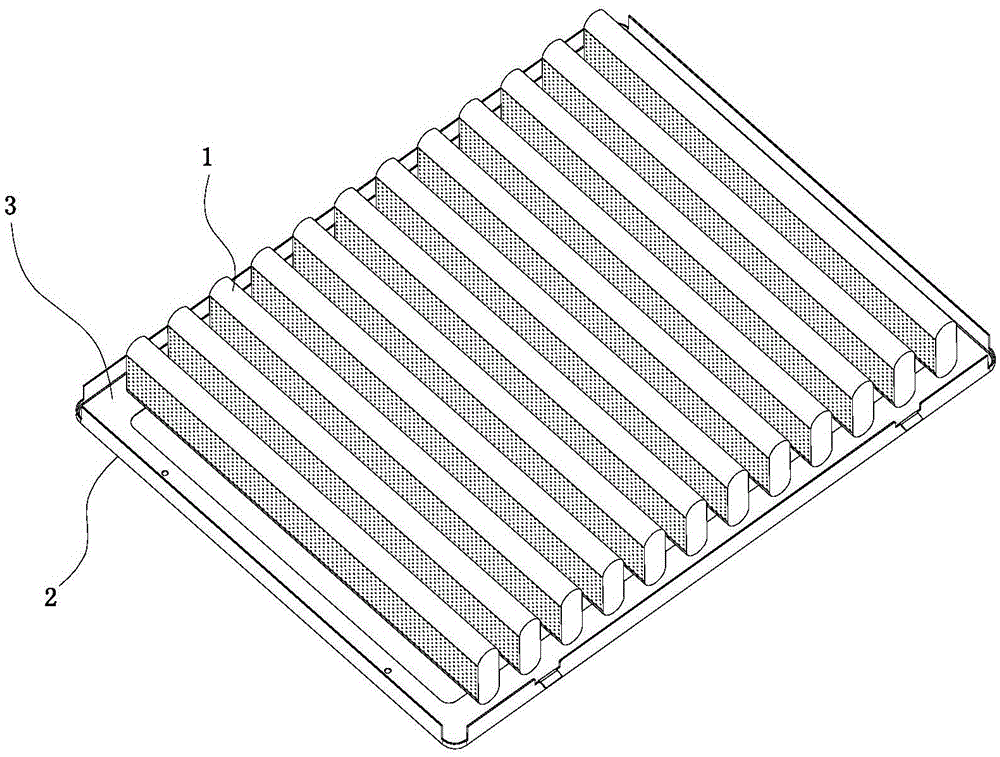

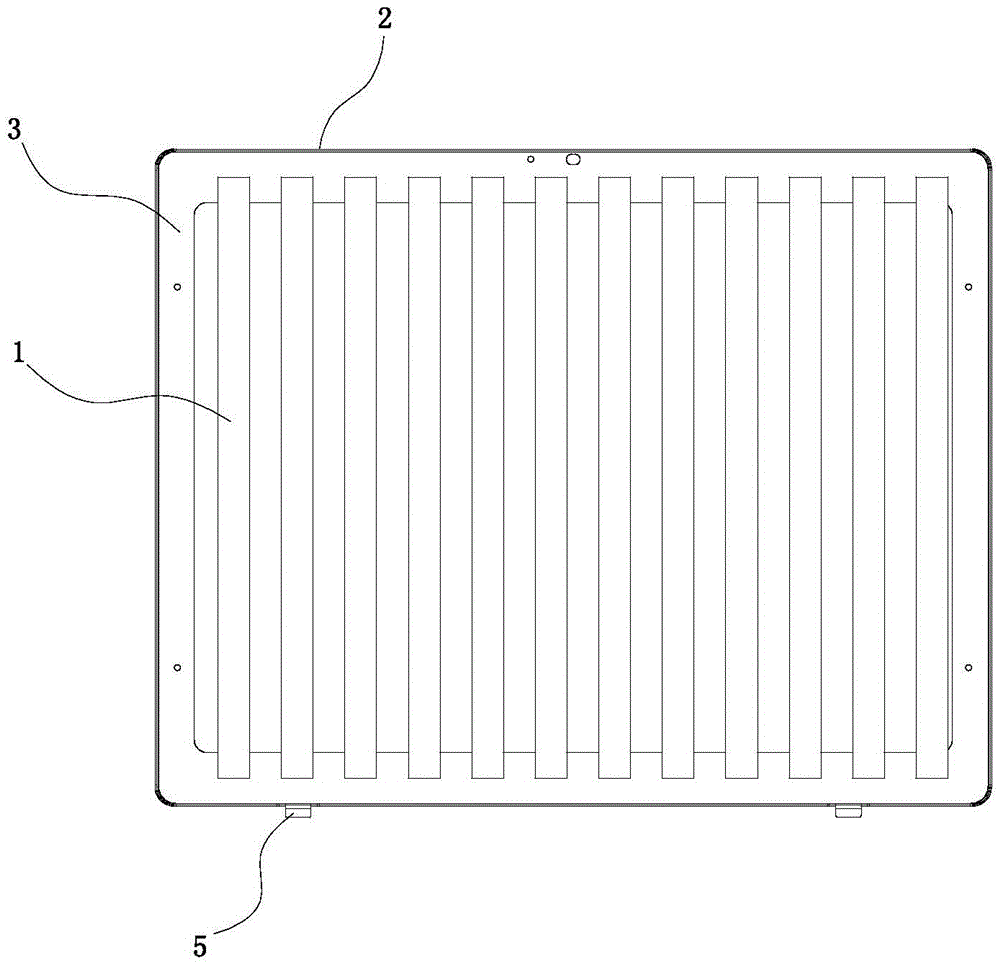

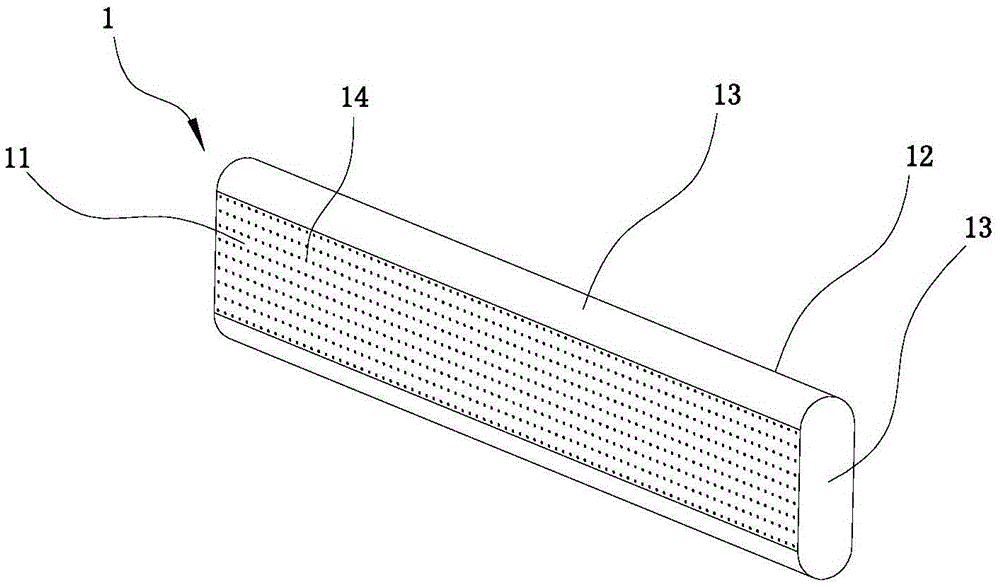

[0019] Such as figure 1 , figure 2 As shown, the microporous plate sound-absorbing grille of this embodiment includes a plurality of sound-absorbing sheets 1 installed side by side on the bottom plate 3, and the number of sound-absorbing sheets 1 is set according to the size of the range hood. In the present invention, the sound-absorbing The sheet 1 is arranged in 12 pieces; the bottom plate 3 is installed at the air inlet of the range hood through the connecting frame 2; the sound-absorbing sheet 1 is a strip-shaped cavity structure, including a microporous plate 11 and a back plate 12 on both sides, and the microporous There are side plates 13 transitionally connected between the plate 11 and the back plate 12, and the side plates 13 located on the upper and lower sides have arc-shaped curved surface structures to reduce airflow resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com