Temperature threshold execution device and temperature monitoring system

An actuator and temperature threshold technology, applied in thermometers, measuring devices, thermometers with physical/chemical changes, etc., can solve the problems of many parts and complex structures, and achieve simple structure, large bending degree and high reliability of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

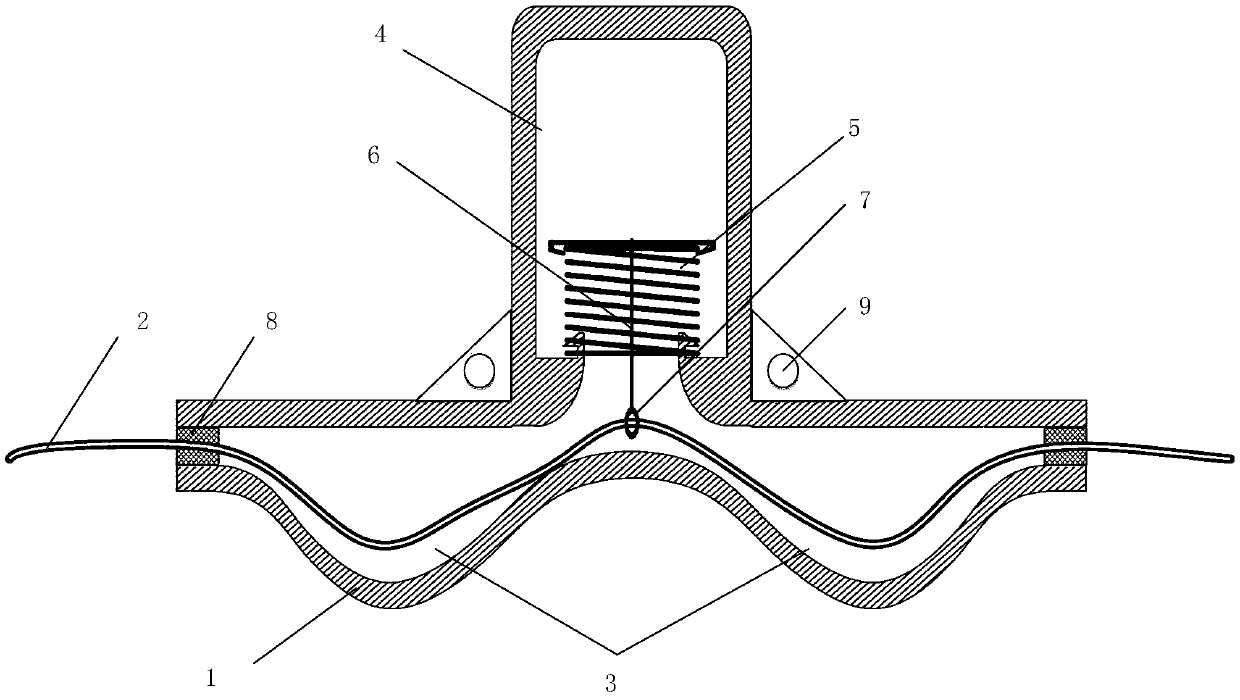

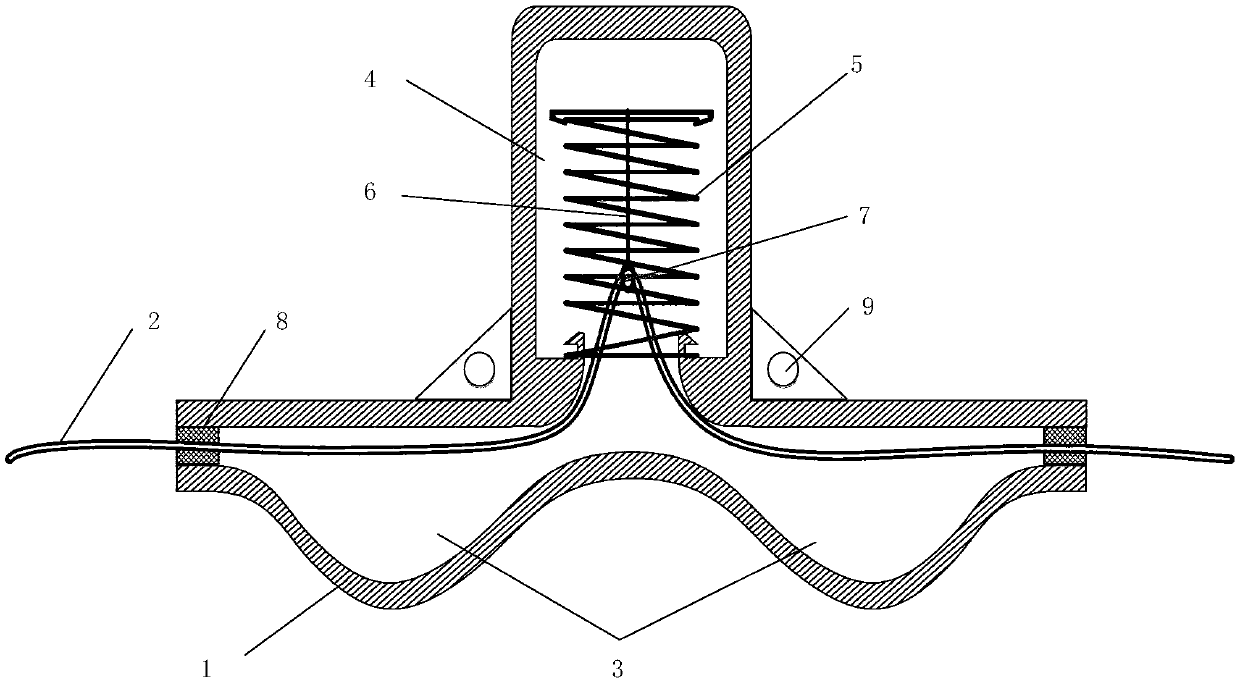

[0041] This embodiment provides a temperature threshold implementing device, which is used to increase the macrobending loss when the temperature changes, so that the loss of the optical fiber reaches a predetermined threshold and is detected. Among them, the OTDR technology combined with Rayleigh backscattering and the temperature threshold actuator of the memory alloy is an important quasi-distributed optical fiber temperature alarm system, which lays the single-mode optical fiber along the cable to be monitored. The temperature threshold actuator is placed at the cable joint). When the temperature of the monitoring point reaches the threshold temperature, the actuator will act, causing the fiber loss at this point to increase suddenly. Combined with OTDR technology, the location of the cable fault point can be quickly judged, so the system is accurate and Reliability, mainly depends on the actuator.

[0042] Based on this, a temperature threshold implementation device is pr...

Embodiment 2

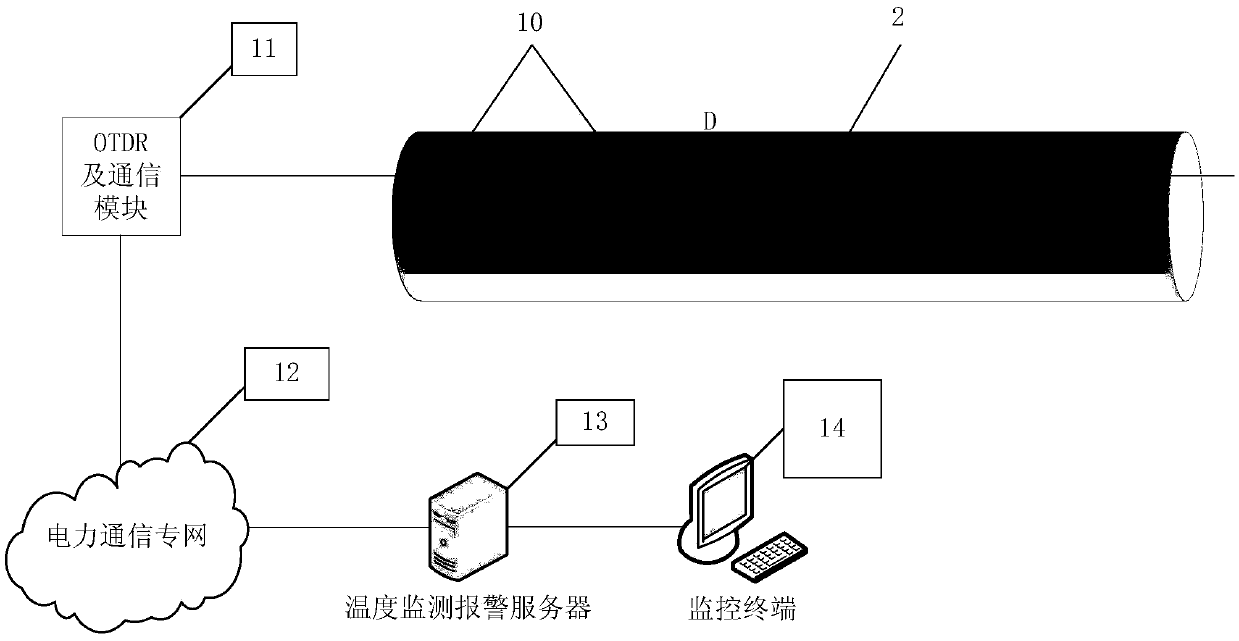

[0054] A temperature monitoring system is provided in this embodiment, such as image 3 shown, including:

[0055] One or more of the temperature threshold actuators 10 described in Embodiment 1 are installed on the optical fiber to monitor the temperature of the optical fiber at the installation position. When the temperature rises, the linkage lever 6 of the temperature threshold actuator operates to turn the optical fiber Pulling into the second chamber 4, the optical fiber produces a large bend. The optical fiber is laid in parallel along the power cable to be monitored, the optical fiber passes through the temperature threshold actuator deployed at the monitoring point, and one end of the 10 optical fiber is connected to the OTDR and the communication module 11 .

[0056] An Optical Time Domain Reflectometer (OTDR for short), connected to the optical fiber. Receive the signal in the optical fiber and generate the loss signal according to OTDR technology.

[0057] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com