Optical testing system used for ship model water surface experiment and testing method thereof

An optical test and ship model technology, applied in the field of ship model and real ship water surface experiment, can solve the problems of attitude sensor and attitude instrument being easily affected by ambient temperature, temperature drift of measurement data, not suitable for ships, etc., and achieves good practical and Market value, simple structure, easy to make and manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

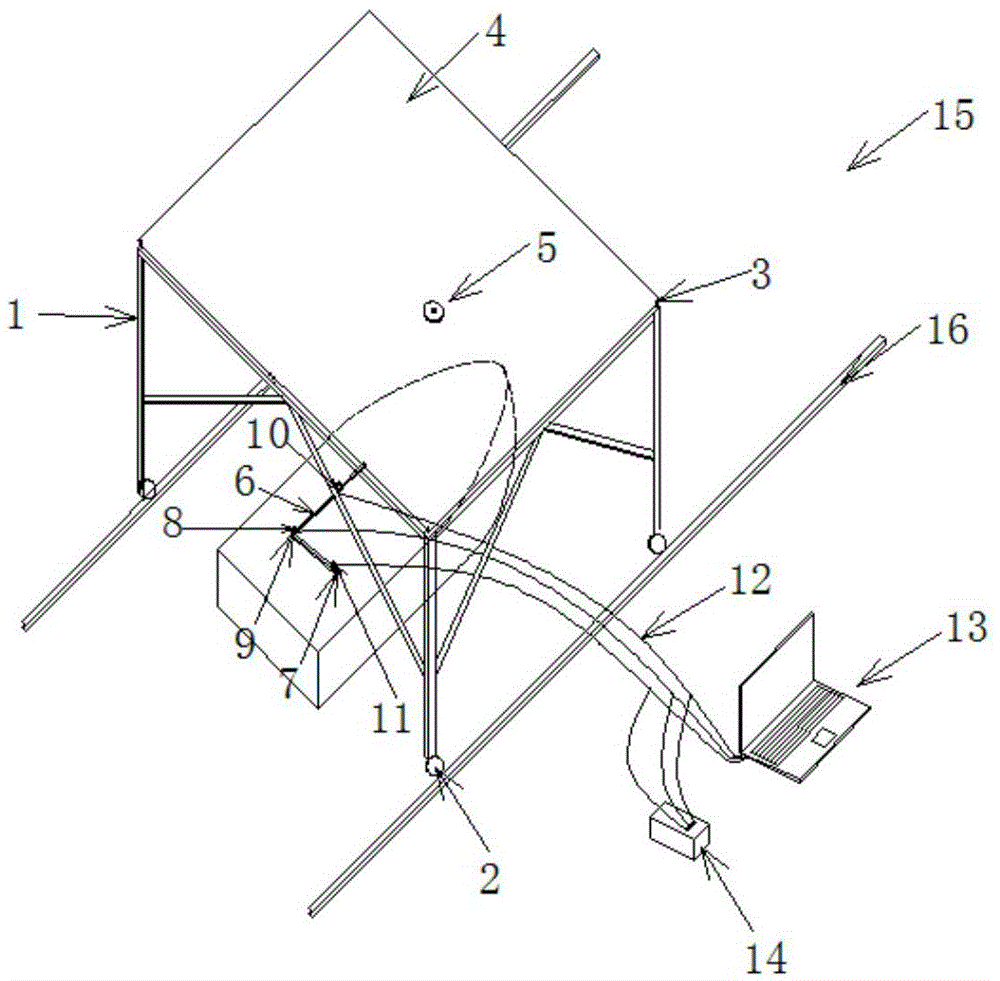

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

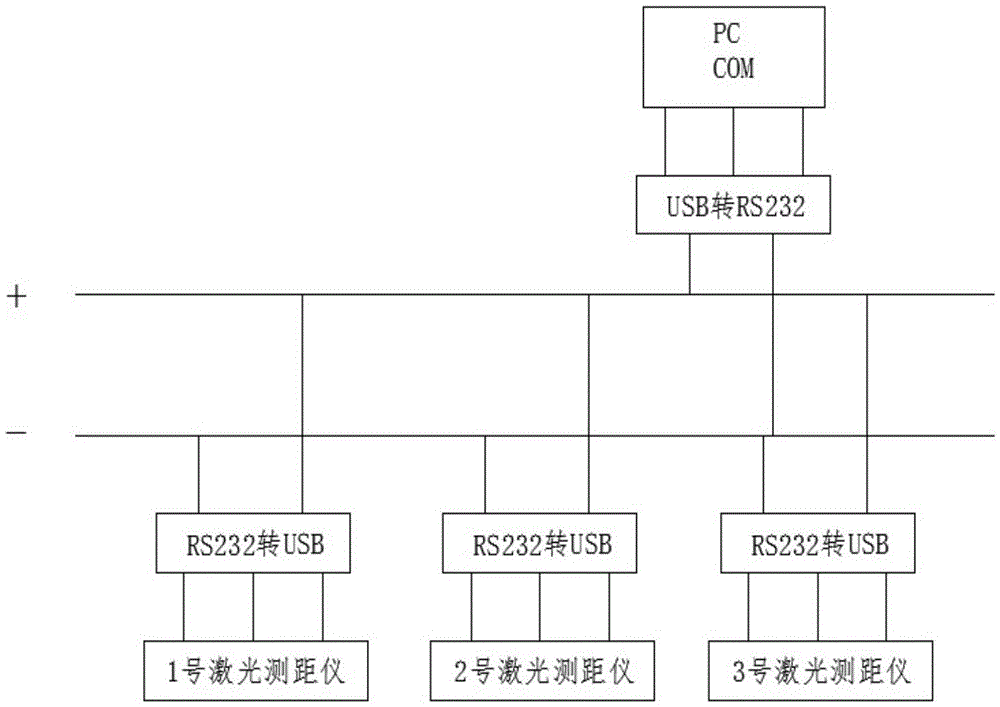

[0060] see figure 1 , the invention includes a reference plane module, a laser layout module, and a data acquisition and analysis processing module mounted on the track of a towed pool or a square pool.

[0061] see figure 2 , the frame 1 of the reference plane module is welded by angle steel, and the guide wheels 2 are installed at the lower ends of the four pillars of the frame 1 so that the reference plane module 1 can slide freely with the movement of the ship model on the guide rail of the pool to keep the reference plane above the ship model, and the upper ends of the pillars Adjusting bolts 3 are installed, and the panel 4 is a toughened glass plate with a flatness error of 0.45 μm installed on the four adjusting bolts 3. A level 5 is installed at the center of the upper surface of the panel 4. By adjusting the four adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com