Temperature sensing optical cable and its preparation method

A temperature sensing optical cable and temperature control technology, applied in optics, light guide, cladding optical fiber, etc., can solve the problems of signal drift, optical cable loss of sensing function, short service life of temperature sensing optical cable, etc., and achieve the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

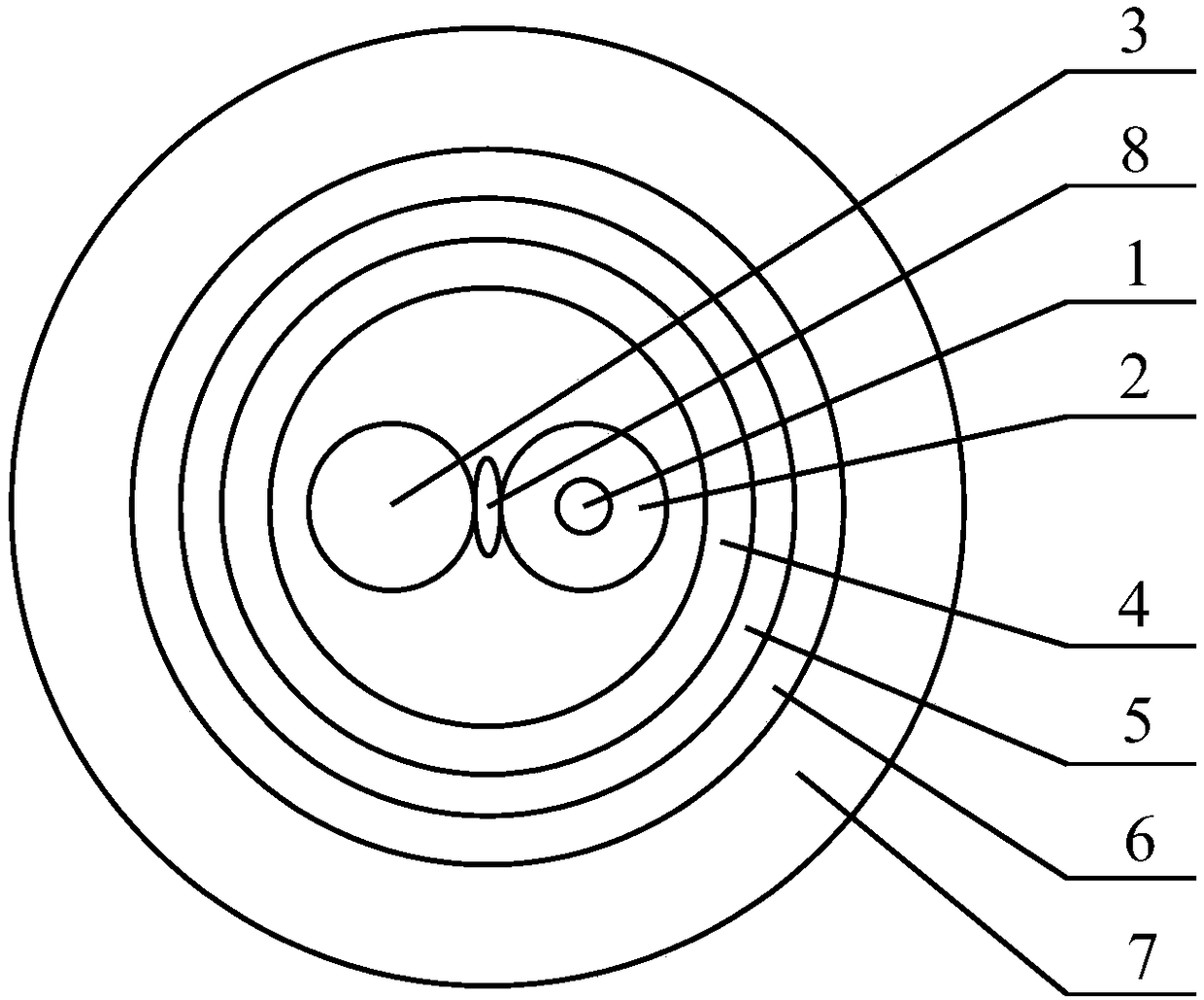

[0041] see figure 1 As shown, the embodiment of the present invention provides a temperature sensing optical cable, the temperature sensing optical cable includes a cable core, a spiral sheath 4, and an outer sheath 7 arranged in sequence from the inside to the outside, and the cable core includes a tight sleeve optical fiber, wherein, The cable core also includes a shape memory alloy wire 3 equal to the length of the tight-buffered optical fiber. The shape-memory alloy wire 3 is made of a shape-memory alloy with a two-way memory effect. The shape-memory alloy wire 3 and the tight-buffered optical fiber are all arranged in the axial direction. and fixed together.

[0042] The embodiment of the present invention also provides a method for preparing the above-mentioned temperature sensing optical cable, comprising the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com