Electric blanket automatic wiring needle punching machine

An automatic wiring and electric blanket technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of short time consumption and cumbersome wiring of electric blankets, and achieve short time consumption, convenient automatic production, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

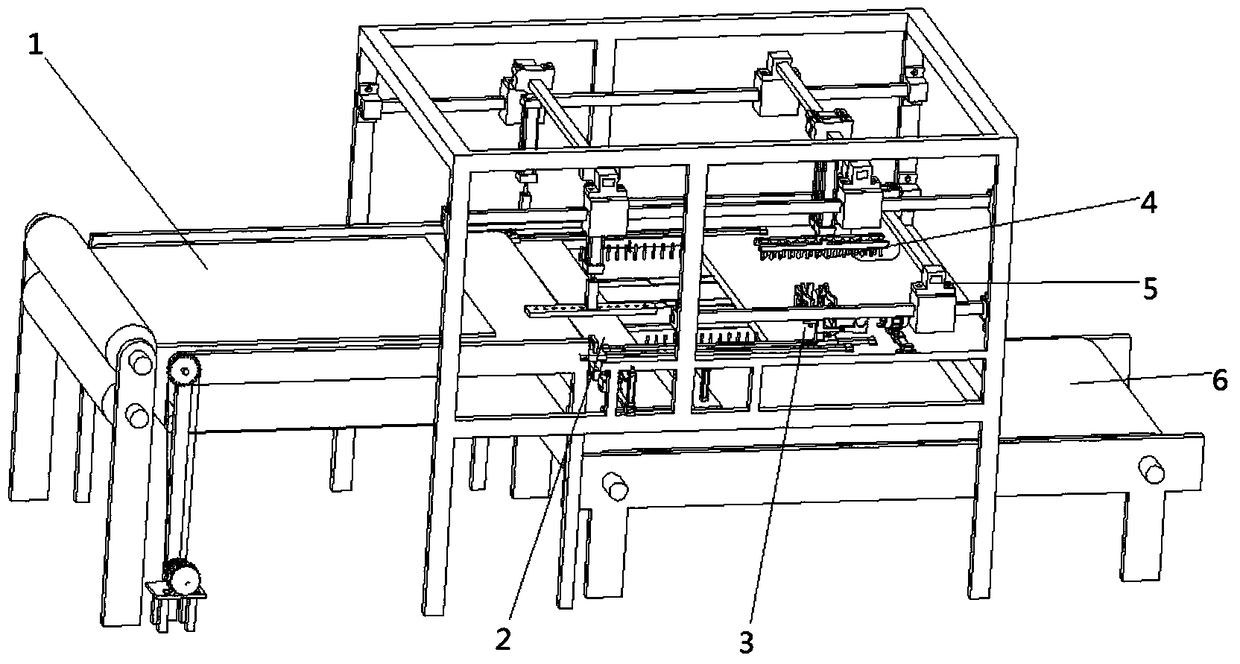

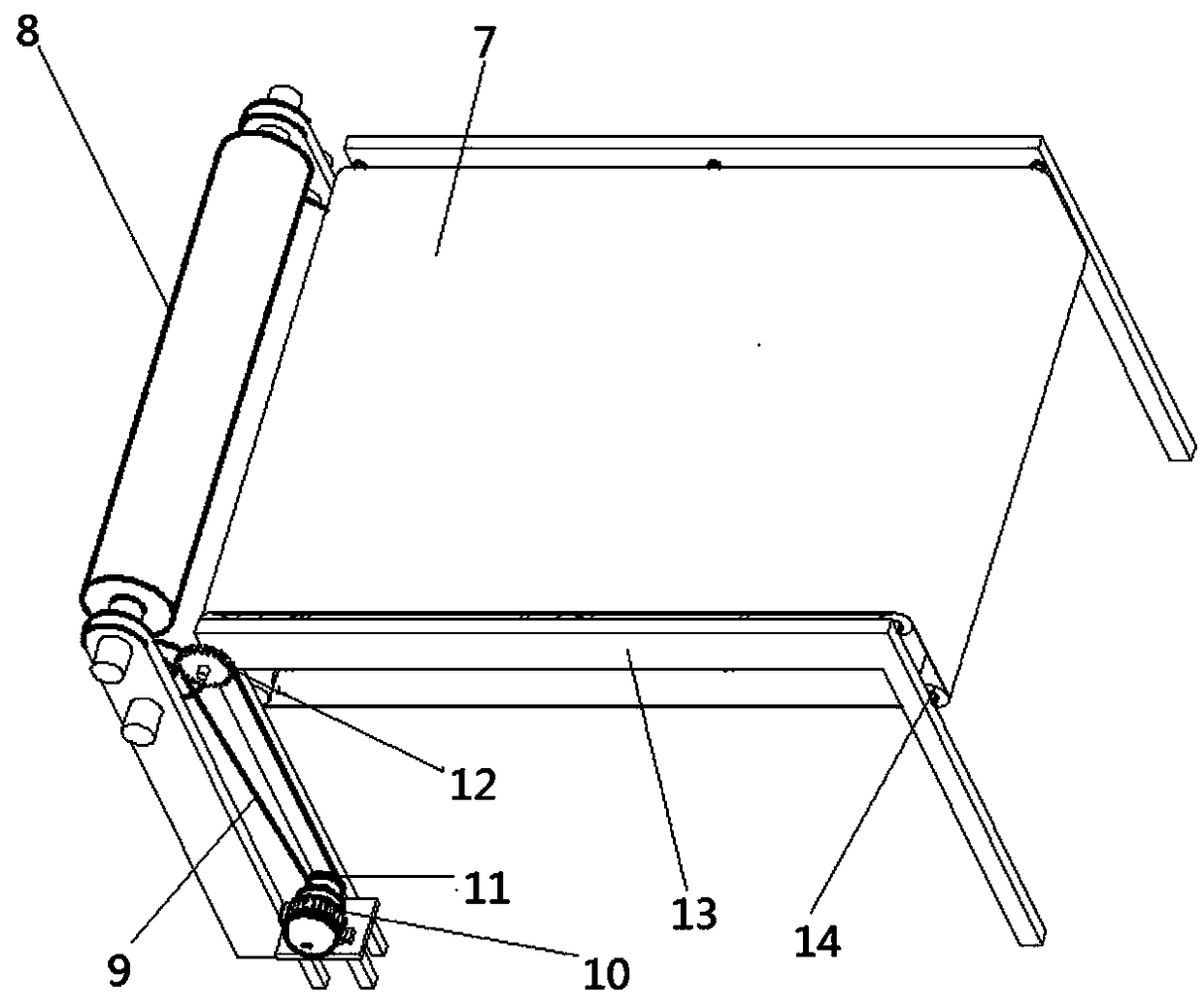

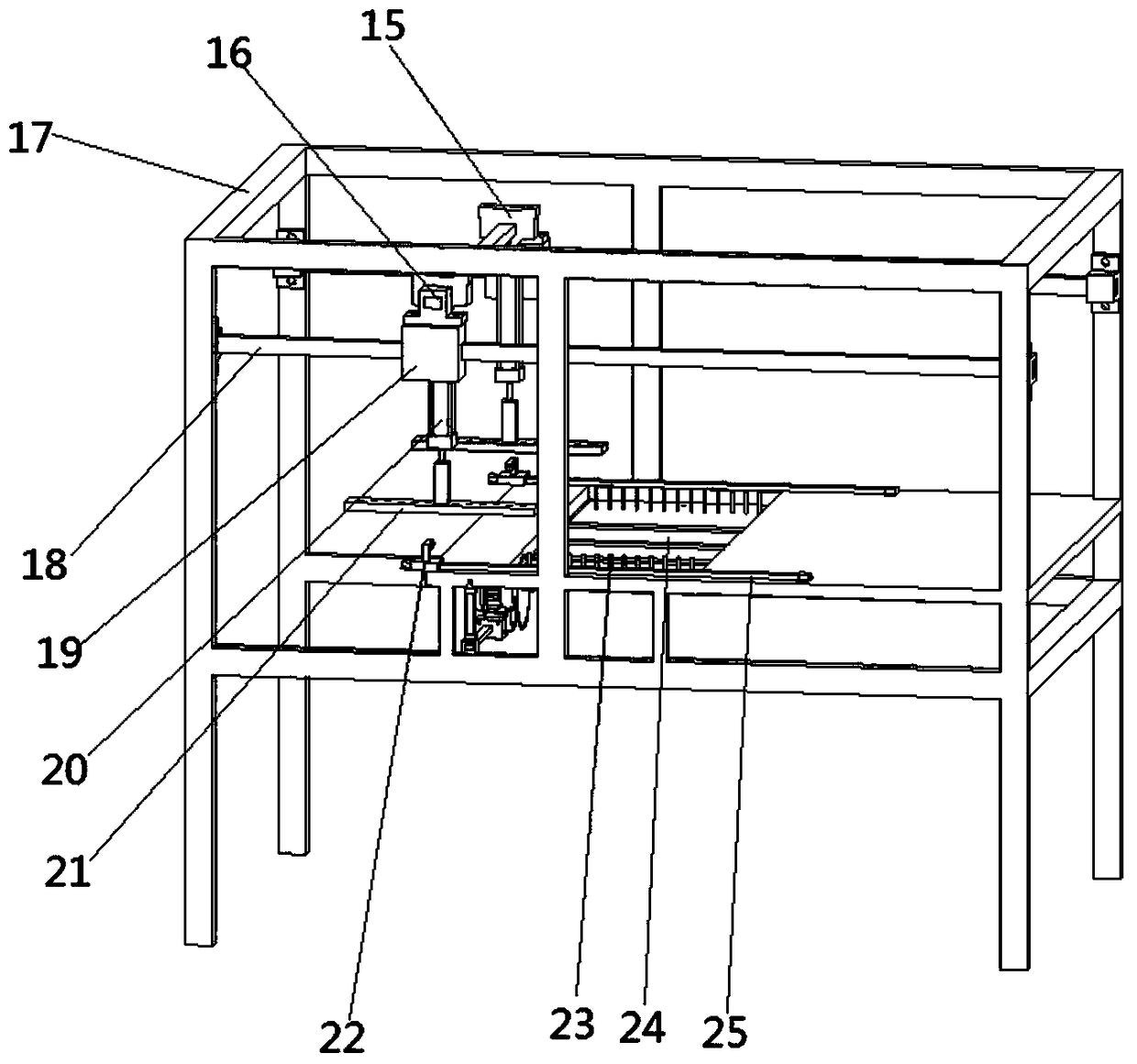

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a working frame 17, a cloth conveying unit 1, a cloth cutting and positioning unit 2, a thread breaking unit 3, a wiring unit 4, a sewing unit 5 and an electric blanket output unit. The cloth conveying unit 1 cooperates with the cloth cutting and positioning unit 2 , and the wire setting and breaking unit 3 cooperates with the wiring unit 4 . Among them: the cloth conveying unit 1 is located at the left end of the work frame, the cloth cutting and positioning unit 2 is located at the front half of the work frame 17, the wire-laying and disconnection unit 3 is placed flat on the work frame 17, and the wiring unit 4 is fixed on the work frame 17 by an electric push rod Above, the electric push rod adopts the second electric push rod 18, the sewing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com