Device for harmless treatment of petroleum microorganism waste bacterium liquid

A harmless treatment and microbial technology, applied in water supply equipment, sanitary equipment for toilets, buildings, etc., can solve problems such as water source and soil pollution, health injuries of experimenters, no harmless treatment of waste bacterial liquid, etc., to achieve Easy to use, good for environmental protection, good effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

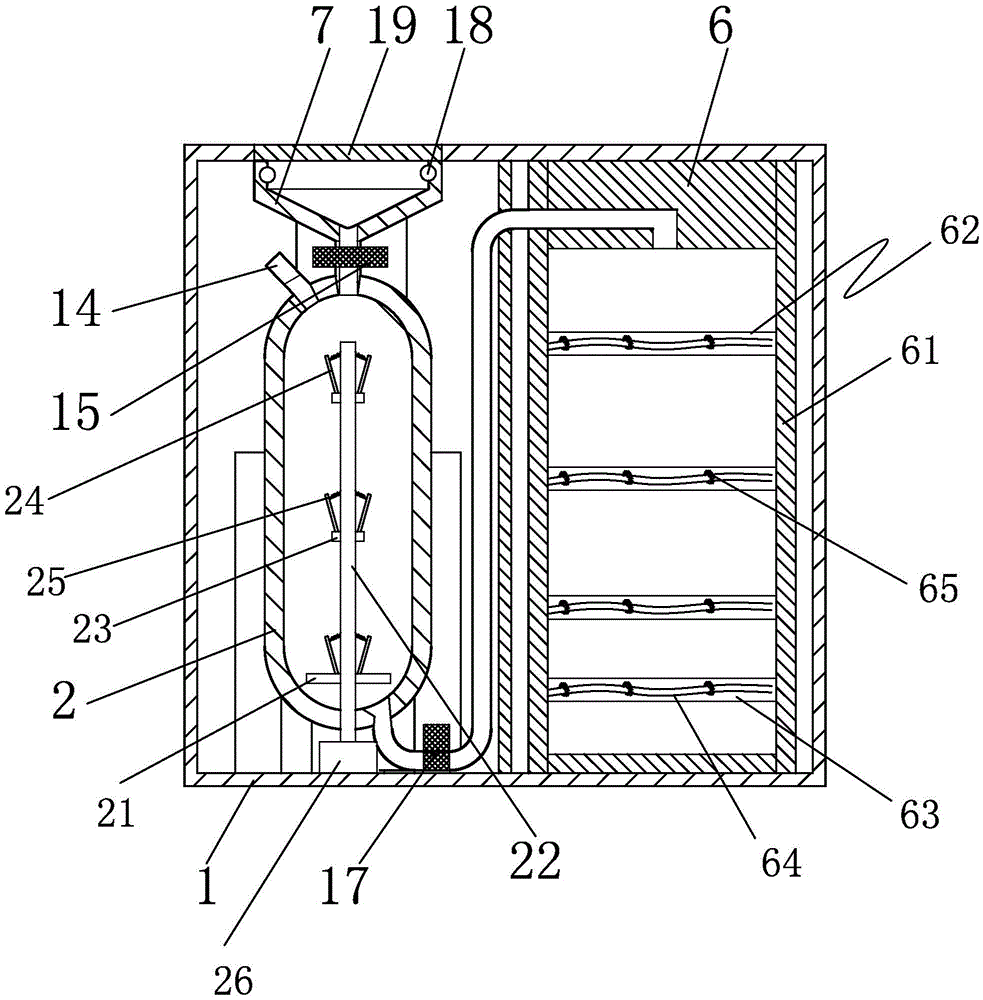

[0034] In the first embodiment of the high-pressure heating tank 2 of the present invention, a pressure limiting valve 14 is installed on the top of the high-pressure heating tank 2, and a heating rod 16 is installed inside the high-pressure heating tank 2, and the number of the heating rods 16 is at least three. And the heating rod 16 is connected with the controller 4 through wires.

[0035] In the second embodiment of the high-pressure heating tank 2 of the present invention, in the present invention, a turntable 21 is provided at the inner bottom of the high-pressure heating tank 2 , and a connecting column 22 is arranged in the middle of the rotating disk 21 . A heating element is arranged inside, and a plurality of connecting plates 23 are arranged at intervals above and below the connecting column 22. Several heating rods 24 are hinged on the connecting plate 23, and the upper ends of the heating rods 24 are connected to the connecting column 22. Extension spring 25 is ...

Embodiment 1

[0038] Antirust paint layer described in the present invention is made up of following components by weight:

[0039]

[0040]

[0041] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and rosin evenly, grind in a conical grinder until the fineness is <50 μm, then add silicone-modified acrylate emulsion, dibutyl phthalate Ester, propylene glycol methyl ether and other components are dispersed uniformly by ultrasonic.

Embodiment 2

[0043] Antirust paint layer described in the present invention is made up of following components by weight:

[0044]

[0045]

[0046] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and rosin evenly, grind in a conical grinder until the fineness is <50 μm, then add silicone-modified acrylate emulsion, dibutyl phthalate Ester, propylene glycol methyl ether and other components are dispersed uniformly by ultrasonic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com