Lotus seedpod type membrane assembly

A membrane module and lotus pod technology, applied in the field of membrane separation, can solve the problems of installation difficulty and difficulty in making full use of the reactor volume, and achieve the effects of ensuring uniformity, improving efficiency and flexibility, and improving volume utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

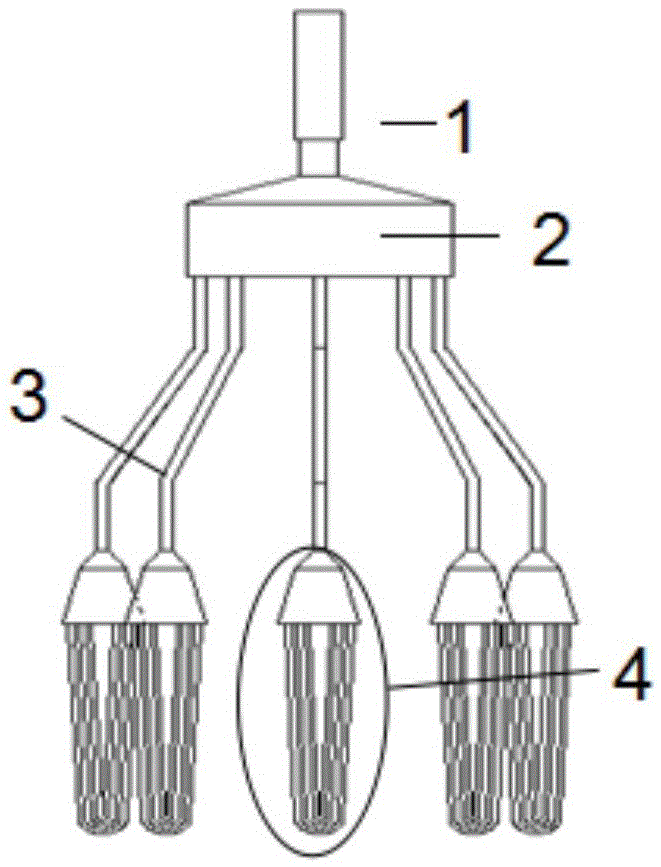

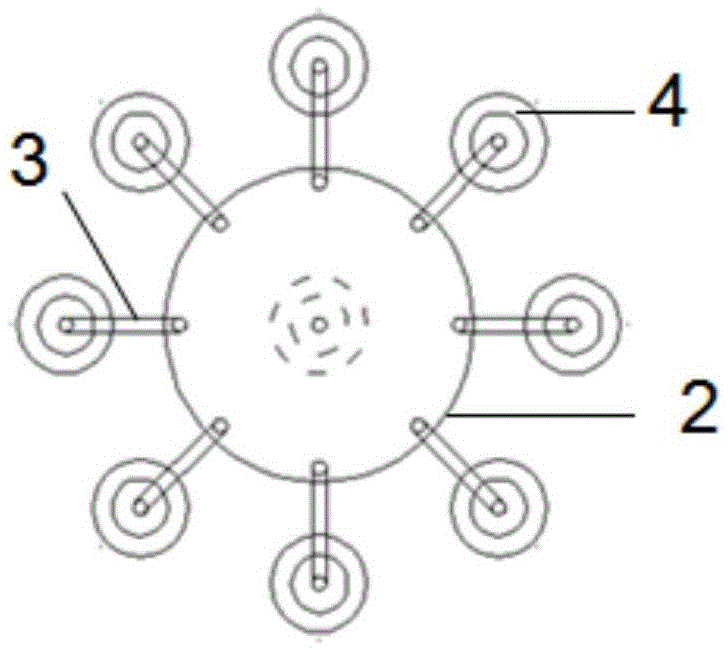

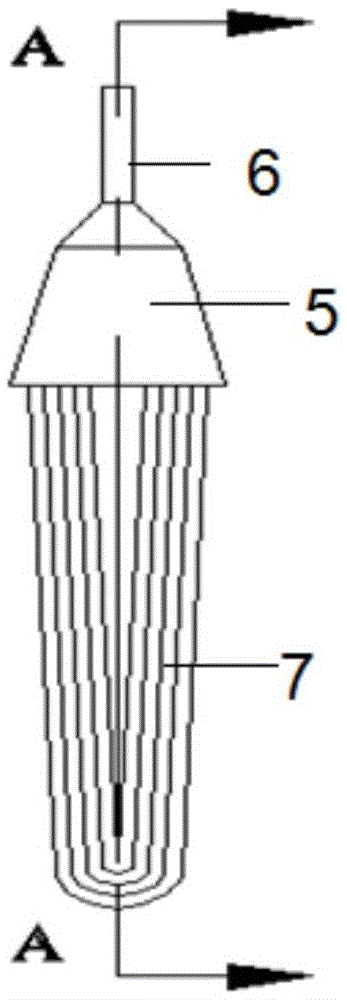

[0032] Figure 1a It is a schematic front view of the shower-type membrane module according to the present invention; Figure 1b It is a schematic top view of the shower-type membrane module according to the present invention. like Figure 1a and Figure 1b As shown in , the shower-type membrane module provided by the present invention includes: an outlet main pipe 1 , a liquid collection cap 2 , a liquid collection pipe 3 and a membrane unit 4 . The number of membrane units 4 is preferably an even number. The shape of the liquid collecting cap 2 is a symmetrical design, that is, it can be a circle or a regular polygon. The lower end portion of the liquid collecting pipe 3 is preferably designed to be vertically downward. As an example, the liquid collecting pipe 3 shown in the drawings is a B-shaped, but not limited thereto. The liquid collecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com