Full-automatic automobile instrument panel pointer cap head pressing system

An automotive dashboard, fully automated technology, applied in manufacturing tools, metal processing, metal processing equipment and other directions, can solve the problems of unqualified products, scrapped, no automatic loading and unloading functions, etc., to improve the pass rate, ensure accurate positioning, The effect of improving placement accuracy and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

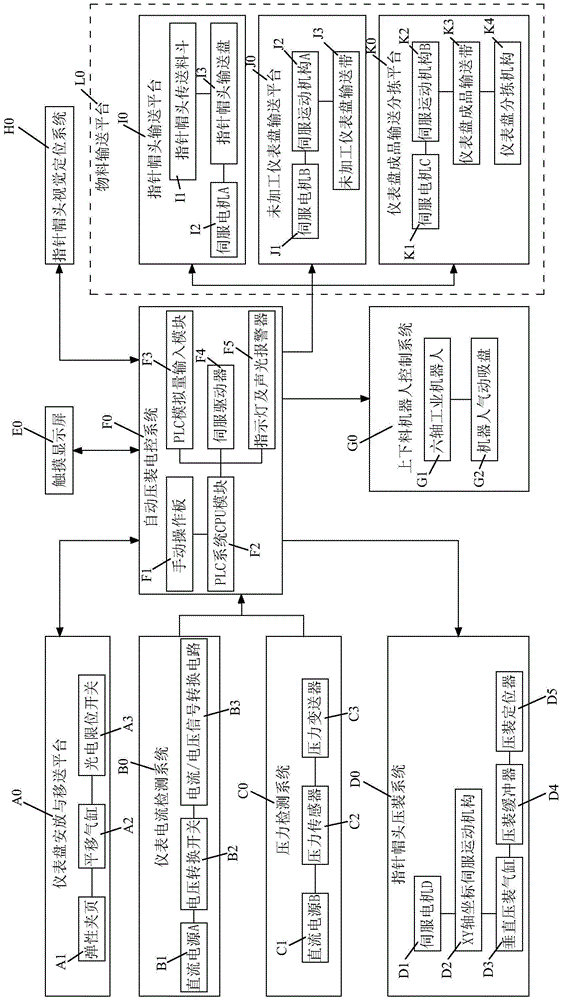

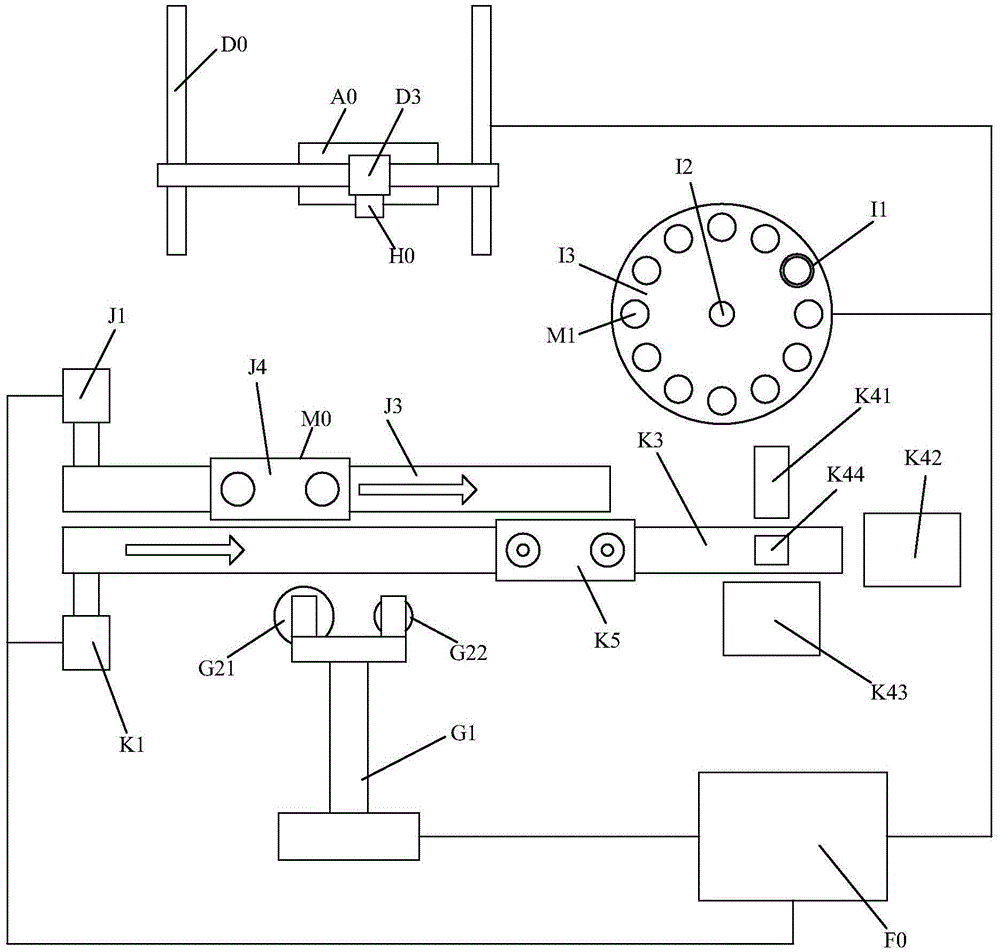

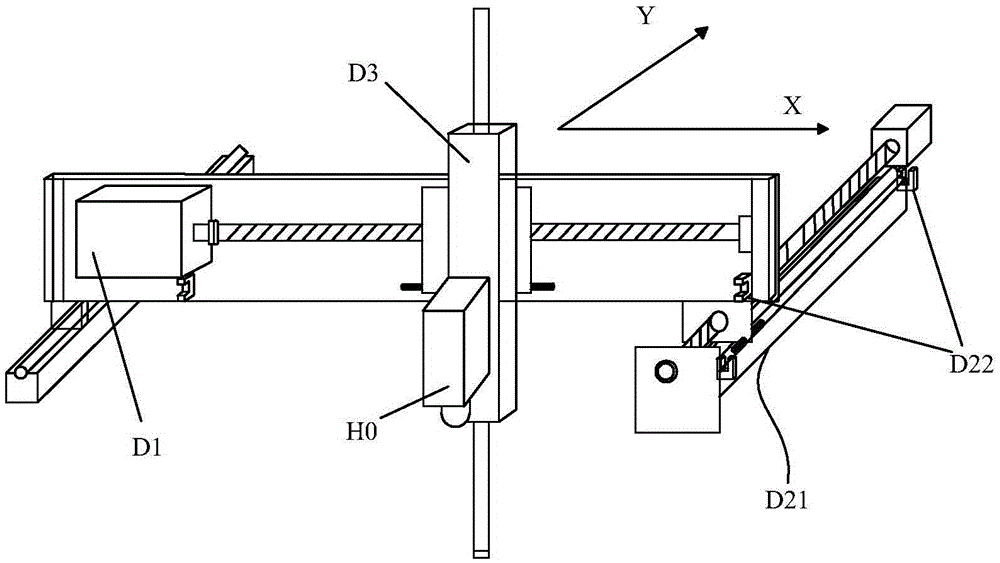

[0055] Such as figure 1 , 3 As shown in and 4, the fully-automated automotive instrument panel pointer cap pressing system includes an instrument placement and transfer platform A0 for horizontally fixing and translating the instrument panel, and an instrument for detecting the current value of the instrument at the moment of power-on and in the normal power-on state Current detection system B0, pressure detection system C0 for real-time detection of the pressure of the press-fitted pointer cap, pointer cap press-fitting system D0 for press-fitting the meter pointer cap, fully automated automobile dashboard pointer cap The pressing system also includes a material conveying platform L0 for horizontally conveying the instrument pointer cap and instrument panel and sorting the finished products, and a control system for loading and unloading robots used to suck and transfer the materials on the material conveying platform L0 to the designated position G0, the pointer cap visual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com