Modified atmosphere packaging machine

A modified atmosphere preservation and packaging machine technology, which is applied to packaging under vacuum/special atmosphere, etc., can solve the problems of waste of fresh-keeping gas, waste of fresh-keeping gas, waste of fresh-keeping gas, etc., and achieve the effect of saving cost and saving fresh-keeping gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

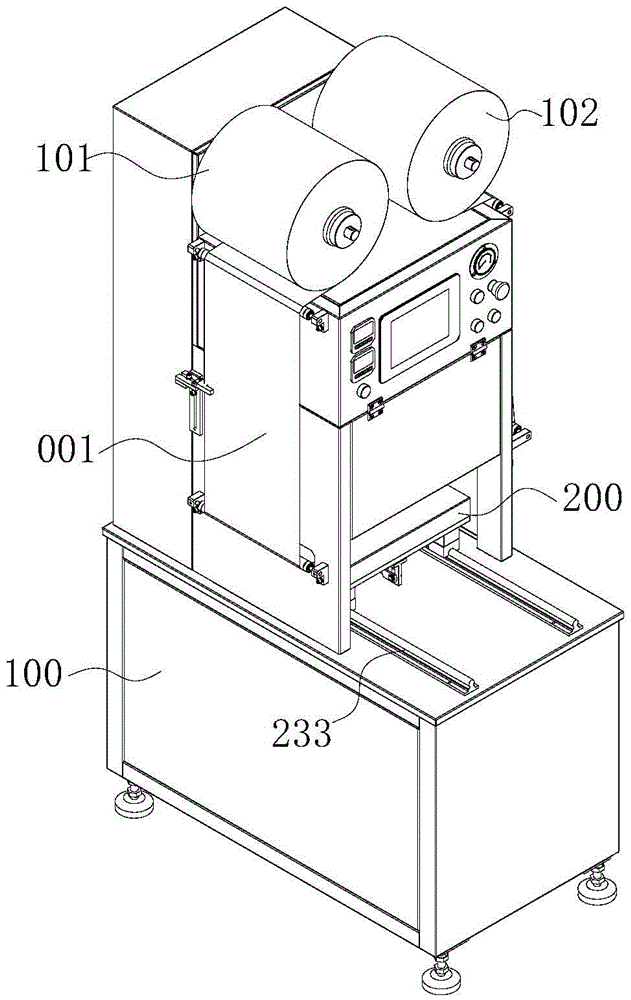

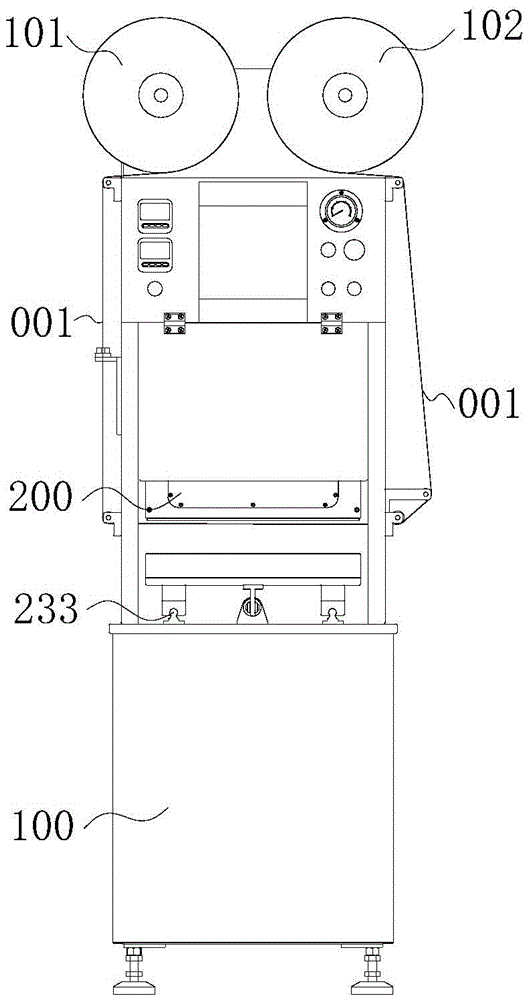

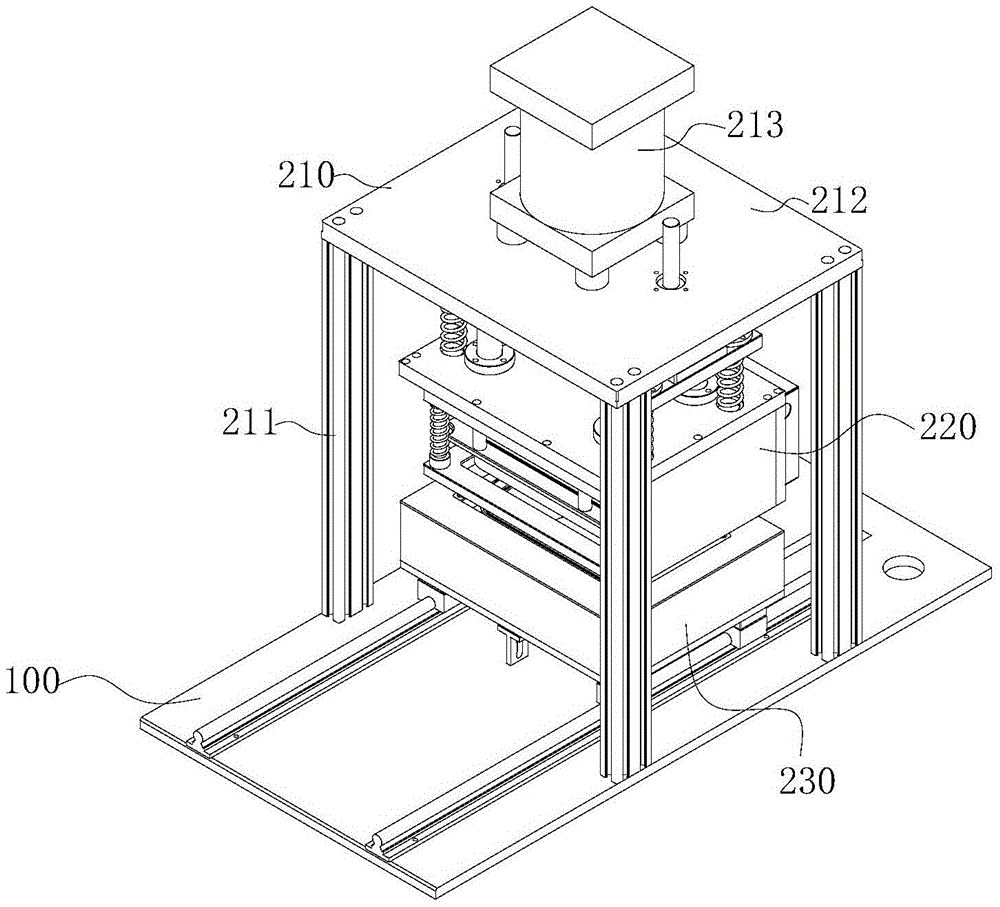

[0024] A modified atmosphere fresh-keeping packaging machine, comprising a frame 100, the frame 100 is provided with a packaging tube 101, a recovery tube 102, and the packaging film 001 is wound on the packaging tube 101; on the frame 100, the packaging tube The mold assembly 200 is arranged below the 101, the mold assembly 200 includes a mold bracket 210, the mold bracket 210 includes a leg 211, the lower part of the leg 211 is connected to the frame 100, and the upper part is connected to the support plate 212;

[0025] It is characterized in that: the first guide rod 215 that can slide in the vertical direction is sleeved in the through hole at the corresponding position on the support plate 212, the lower part of the first guide rod 215 is connected with the connecting plate 214, and the support plate The upper surface of 212 is connected with the cylinder body of the lower pressure cylinder 213, the piston rod of the lower pressure cylinder 213 passes through the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com