Patents

Literature

31 results about "Modified atmosphere/modified humidity packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified atmosphere/modified humidity (MA/MH) packaging is a technology used to preserve the quality of fresh produce so that it can be sold to markets far away from where it is grown, extend the marketing period, and to help suppliers reduce food waste within the cold chain. Commercial examples of MA/MH include sea freight of Galia and cantaloupe melons from Central and South America to Europe (a 21-day journey) and North America (a 7-day journey); transport of white asparagus from fields in Peru to markets in Western Europe (a 20-day journey by land and sea); and trucking of cherries from orchards in Turkey to supermarkets in the UK (a 7-day journey).

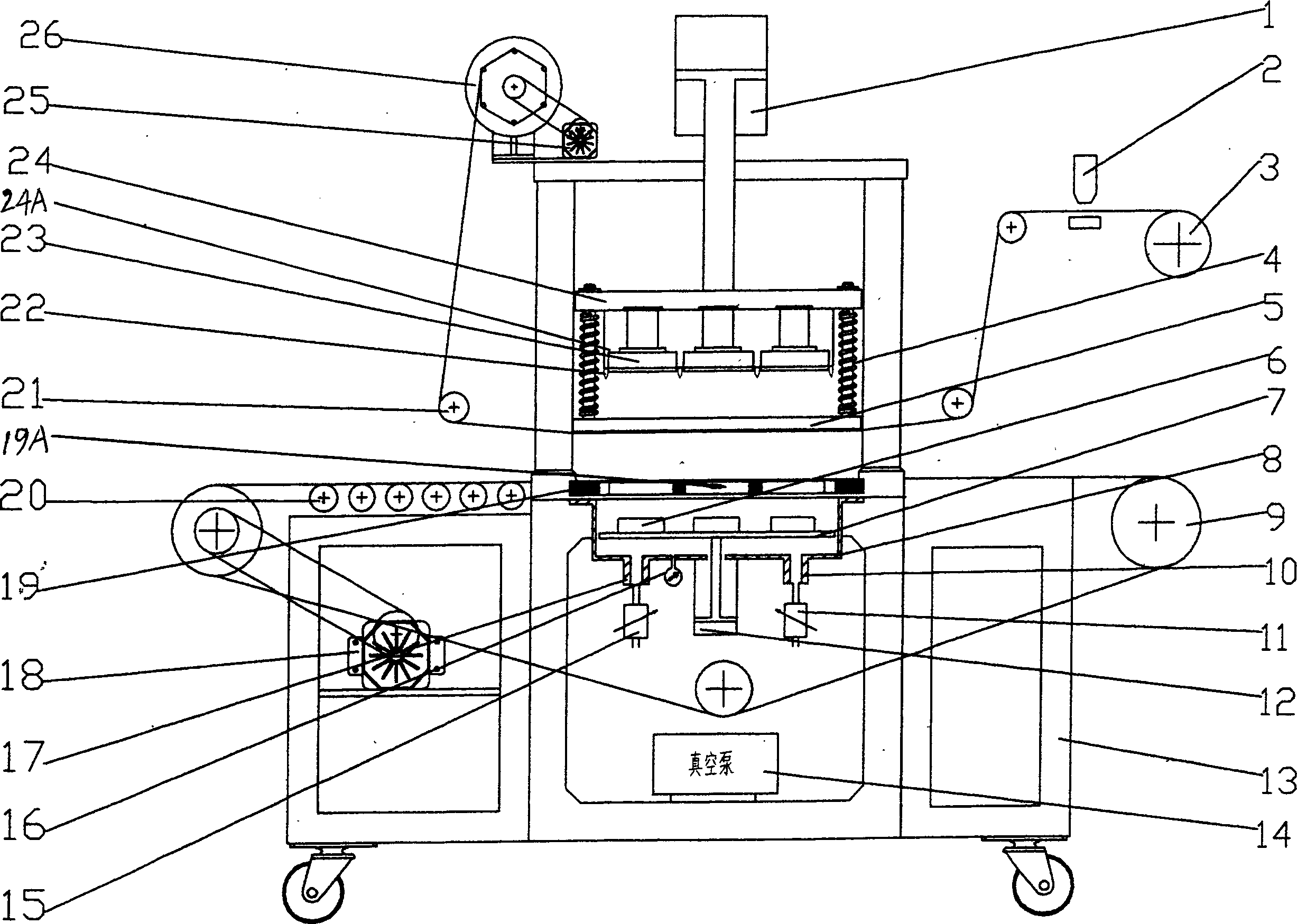

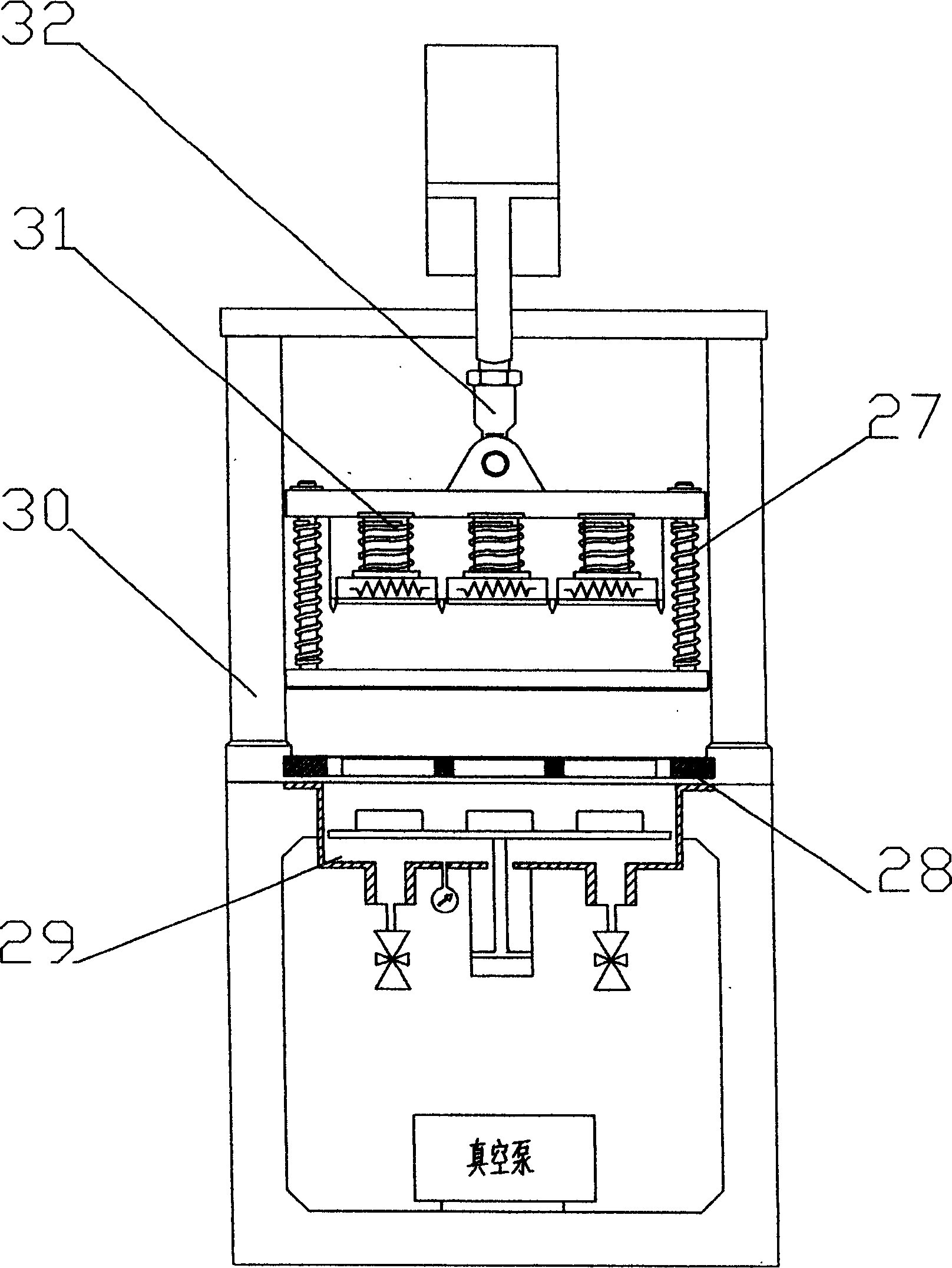

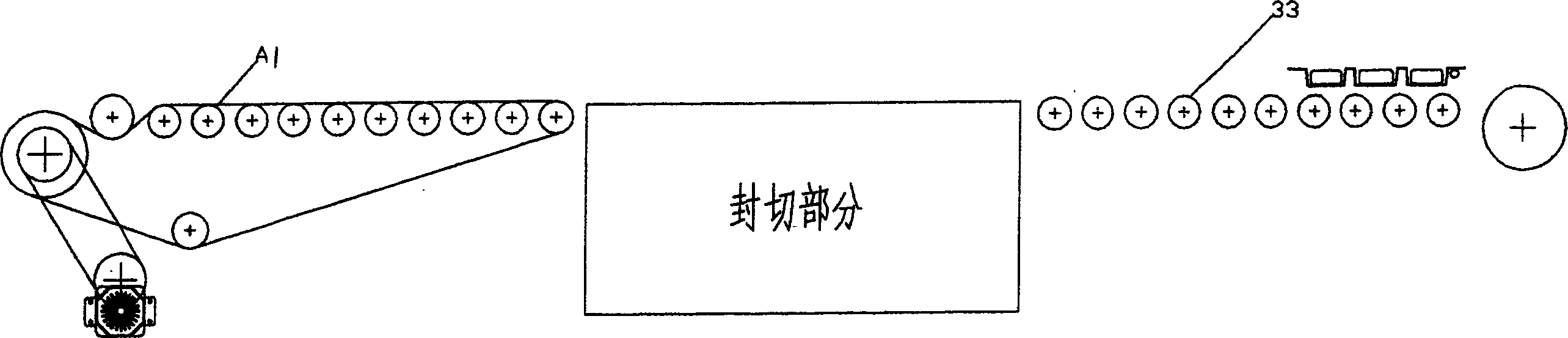

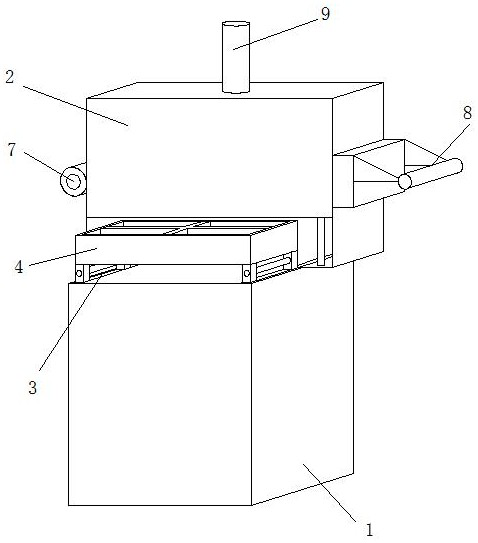

Continuous casing cake and food air conditioned preserving packers

InactiveCN1644458AAccurate identificationMake sure you are in a safe placePackaging under special atmospheric conditionsThin membraneEngineering

A continuous packing machine with gas antistaling function for the cake food box is composed of machine frame, pressure-variable sealing-cutting unit, conveyer, heating-sealing unit, cutting unit, vacuumizing-inflating unit, film winding unit, and controller. Said heating-sealing unit has upper and lower sealing dies.

Owner:苏明智

Industrial process of pot-stewed meat food

InactiveCN101019615AAvoid pollutionShorten the timeFood preservationFood preparationEngineeringAir conditioning

The industrial process of producing pot-stewed meat food includes the following steps: pre-treatment of material, scalding, pot-stewing in soy sauce, vacuum cooling in a constant temperature cleaning shop to below 10 deg.c, cutting with a high speed slicing machine in a constant temperature cleaning shop, weighing and packing in box, and final packing in an air conditioning and preserving package machine. The present invention has high production efficiency, and the pot-stewed meat food has stable quality, long preservation period and other advantages.

Owner:徐少东

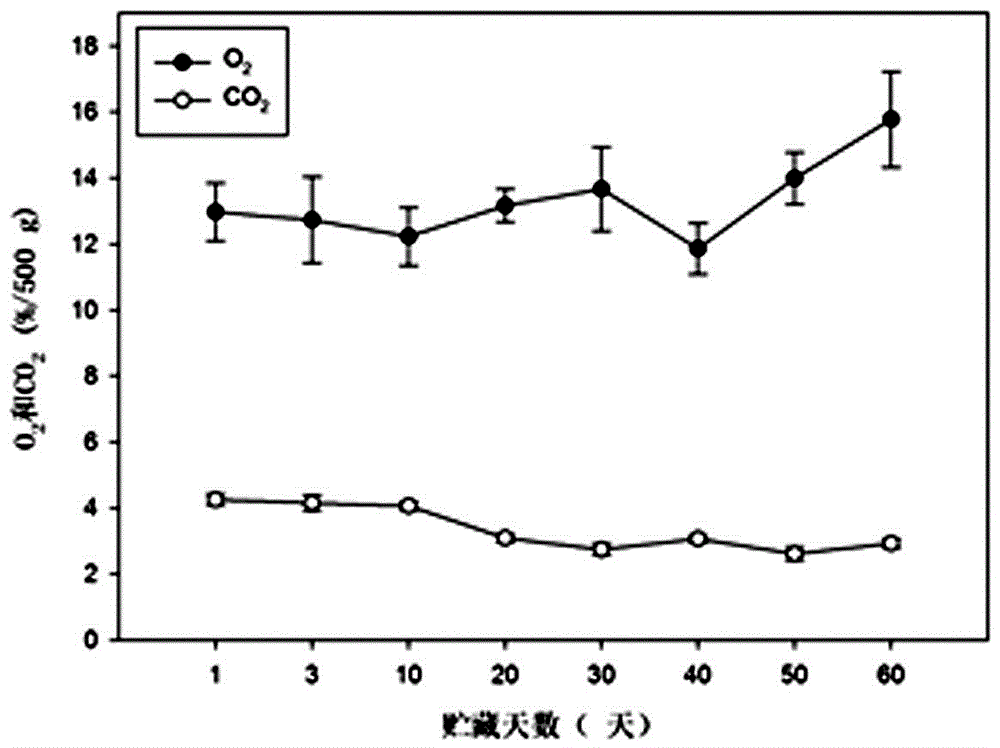

MAP (modified atmosphere packages) preservation method for picked broccoli

ActiveCN105994593ANo wilting and dehydrationNo inflorescence chlorosisFruits/vegetable preservation by freezing/coolingFlavorWater vapor

The invention provides an MAP (modified atmosphere packages) preservation method for picked broccoli. The MAP preservation method comprises the following steps: (1) pretreatment of the picked broccoli: fresh and healthy broccoli without apparent damage is subjected to rapid precooling treatment after picking, and the core temperature is reduced to 0-1 DEG C; (2) preserved MAP: single precooled broccoli or multiple pieces of precooled broccoli are loaded into a polyethylene preservation packaging bag for sealed packaging, the O2 permeability coefficient of the polyethylene preservation packaging bag is 10,000-20,000 cm<3> / m<2>.24h.0.1 MPa, the CO2 permeability coefficient of the polyethylene preservation packaging bag is 6,000-8,000 cm<3> / m<2>.24h.0.1 MPa, and the water vapor transmission of the polyethylene preservation packaging bag is 20-30 g / m<2>.24h; (3) cold storage for preservation: the bagged broccoli subjected to preservation packaging treatment with the polyethylene preservation packaging bag is stored, transported or sold in a cold storage preservation storehouse or a cold storage wagon at the temperature of 0-1 DEG C. The method is simple and convenient to operate, quality deterioration phenomena such as withering and water loss, green fading and yellowing of inflorescence, rot, deterioration and the like of the fresh broccoli after picking can be relieved effectively, special nutrition and flavor of the broccoli in the storage period are kept, the shelf life is prolonged, and popularization and application are easy.

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI +1

Air conditioned fresh-keeping method for pseudosciaena crocea

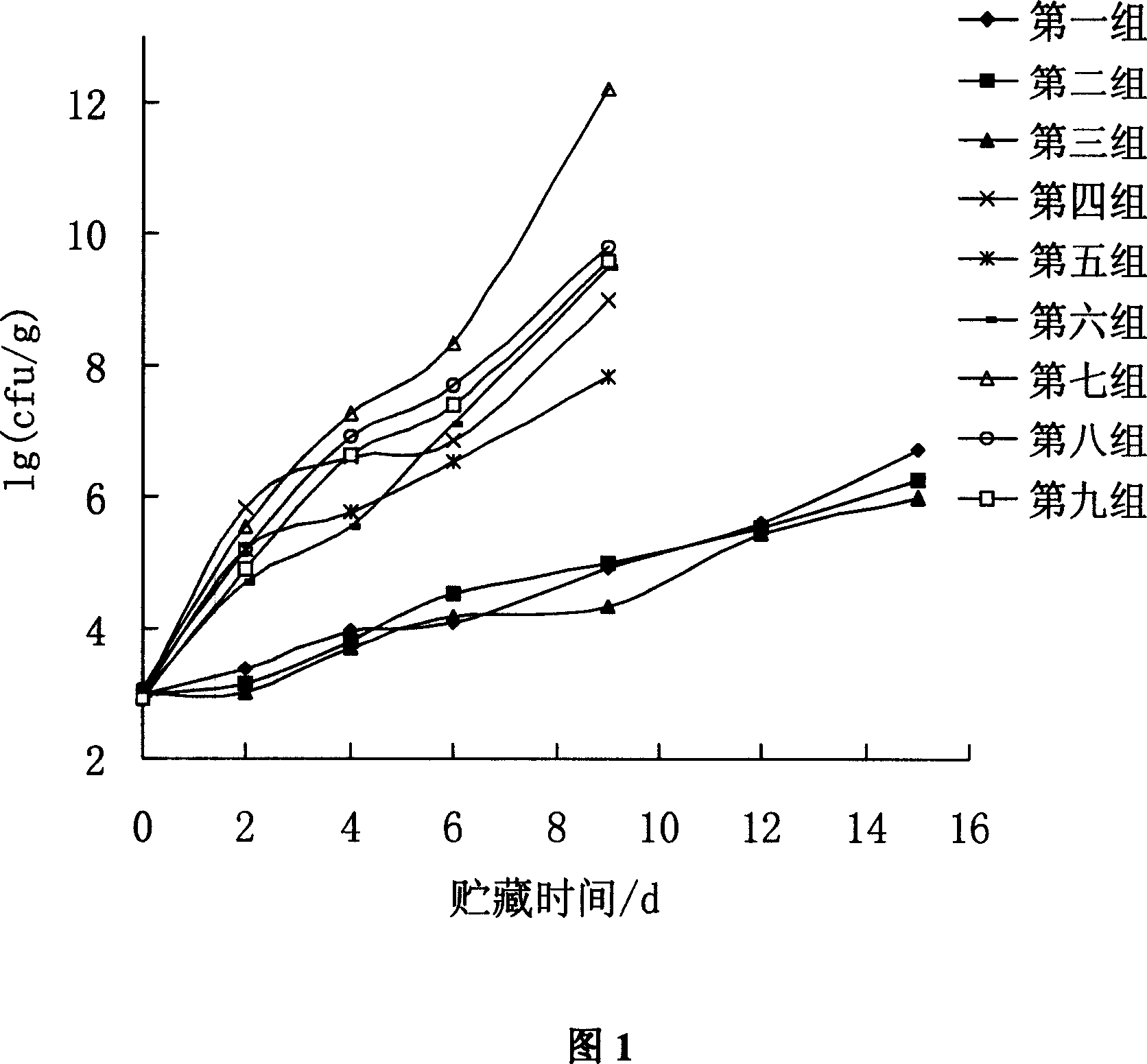

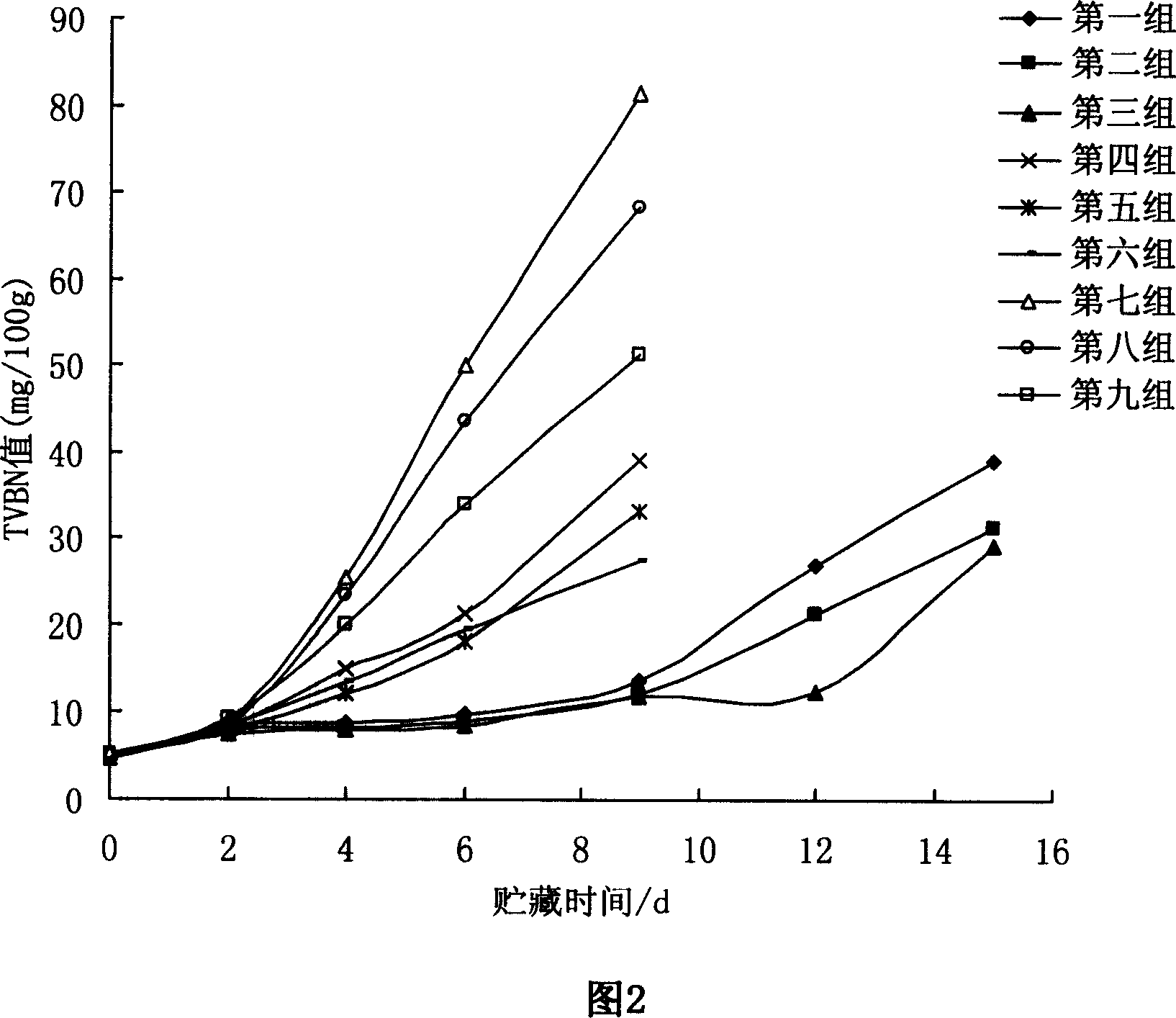

InactiveCN101006799AExtended delay periodInhibit rapid reproductionMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsBiologyModified atmosphere/modified humidity packaging

The invention discloses a packaging method for refreshing large yellow croaker through controlled atmosphere. The method comprises: (1) killing, dissecting, removing internal organs of the fish, washing, and drip-dring, (2) mixing gases with a gas proportion mixer, vacuumizing with a multifunctional controlled atmosphere packaging machine for 3-10s, aerating for 1-5s, and sealing at 110DEG C-150DEG C, and (3) cold-storing at 0DEG C-4DEG C. Controlled atmosphere adopts CO2 and N2, and takes random ratio at a volume scope of CO2 10-80% and N2 10-90%. In the controlled atmosphere packaging, aerating 1ml-3ml / g yellow croaker. The invention can prolong shelf period obviously, ensure product quality, and is easy operation.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Controlled release active gas adjustment fresh-keeping packaging material and preparation method thereof

The invention discloses a controlled release active gas adjustment fresh-keeping packaging material and a preparation method thereof, and belongs to the technical field of food and fruit and vegetable fresh-keeping technologies. The packaging material comprises the following main components: 0.5-10 wt% of a natural antibacterial agent, 5-30 wt% of ethylene-vinyl acetate copolymer, 1-45 wt% of block copolymer and no less than 40 wt% of polyolefin master batch, and is prepared through the following steps: mixing the materials according to the ratio; after carrying out melt blending granulation, carrying out film blowing or extrusion molding. As a packaging film of fresh fruit and vegetables, the material can provide relatively suitable humidity (RH70-98%) and suitable oxygen and carbon dioxide gas adjustment packaging atmosphere for fruit and vegetables, and the natural antibacterial agent is slowly released, so that the respiratory action of fruit and vegetables and the growth of fungus on the surfaces of fruit and vegetables are inhibited, and the effect that the fresh-keeping period of fruit and vegetables is prolonged is achieved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

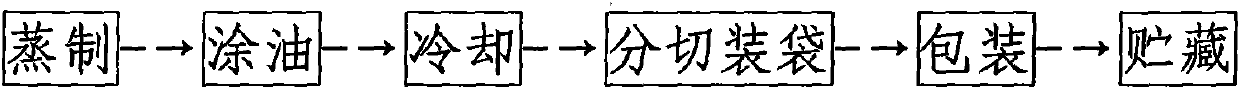

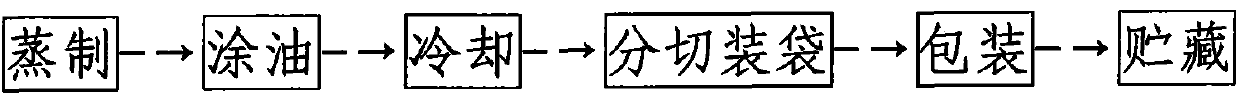

Method for preserving rice chilled noodles

The invention relates to a method for preserving rice chilled noodles, which comprises the following steps of: (1) immersing, cleaning and beating rice, and steaming at high temperature to form a dough-shaped finished product; (2) coating a layer of grease on the surface of the finished product; (3) putting the finished product a container with a cover, conveying the finished product to a purifying chamber, and cooling the surface of the finished product by utilizing a vacuum cooling machine to the temperature of below 10 DEG C; (4) cutting the cooled dough-shaped finished product into strips in the purifying chamber, metering and loading the strips into an air-conditioned preserving packaging bag; (5) putting the air-conditioned preserving packaging bag with the finished product on an air-conditioned machine, pumping air, inflating air-conditioned packaging mixed gas, and packaging; and (6) storing the packaged rice chilled noodles at room temperature or at low temperature of between 4 and 8 DEG C. By the method, the preservation time of the rice chilled noodles produced in Guangyuan, Szechwan is prolonged to 15 days at room temperature or 45 days at low temperature, the original taste and flavor of the rice chilled noodles can be retained completely, and the industrial production is realized, so that the rice chilled noodles become convenient snack food delivered and sold in supermarkets and cooked food stores.

Owner:徐飞

Refrigeration fresh-keeping method for cabbage

InactiveCN104686638AControlled reproductionSlow breathingFruit and vegetables preservationModified atmosphere/modified humidity packagingMoisture

The present invention discloses a refrigeration fresh-keeping method for cabbage. The method is characterized by comprising the following steps: (1) cabbage pretreatment; (2) antistaling agent spraying; (3) precooling operation; (4) sterilization; and (5) packing and preservation in a cold storage. The invention adopts a compound controlled atmosphere fresh-keeping package to reduce the respiration of fresh vegetables, inhibit the metabolism, control the propagation of the bacteria, and prolong the fresh keeping period of vegetables. The added antistaling agent can realize effective disinfection, insecticide and pest control to ensure the quality of fruits and vegetables, and powdered activated carbon can adsorb odor and moisture in the air; and the cabbage can be stored in busy season and sold in off-season to achieve balanced market and increase economic benefits.

Owner:QINGDAO ZHONGTIAN XINDA BIOTECH R & D

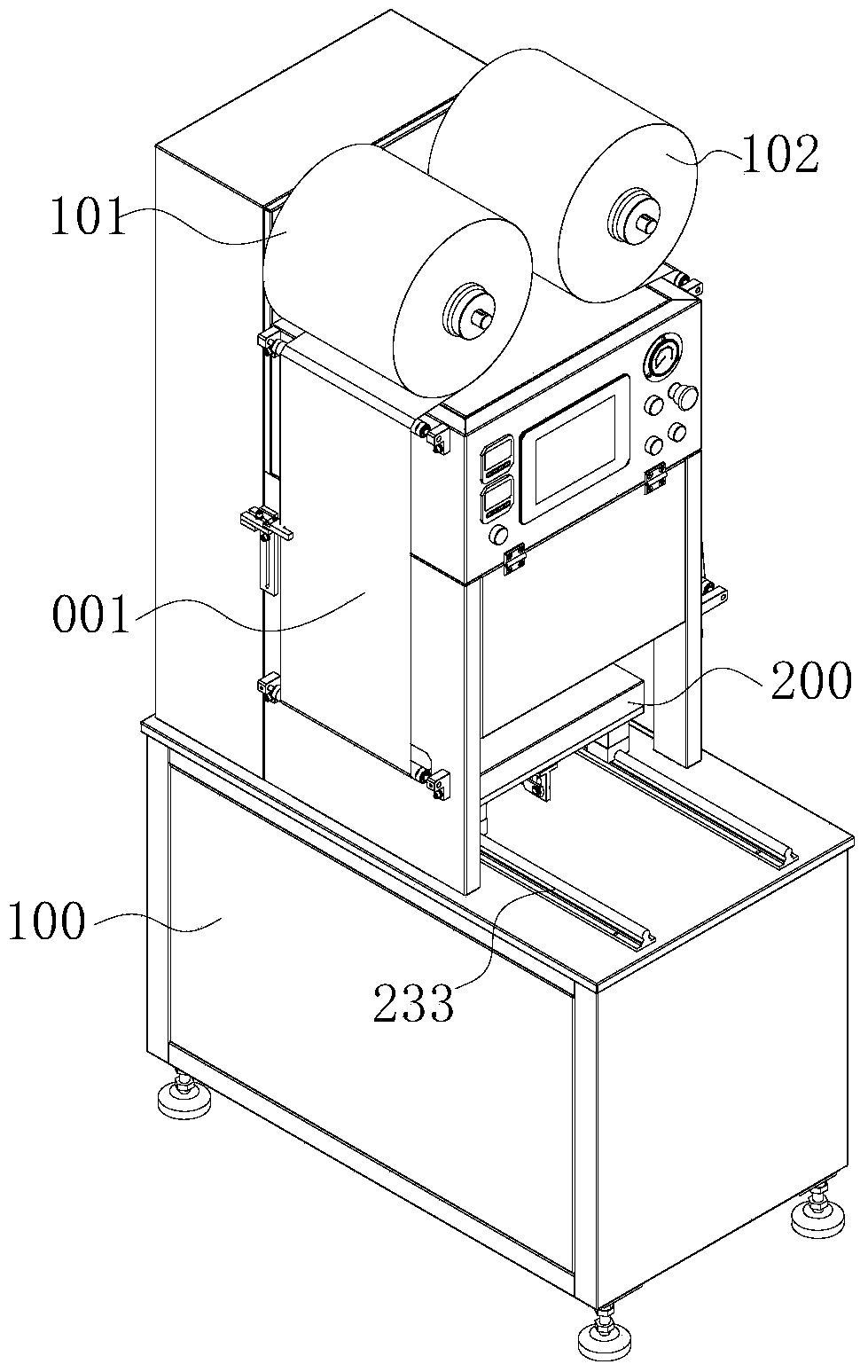

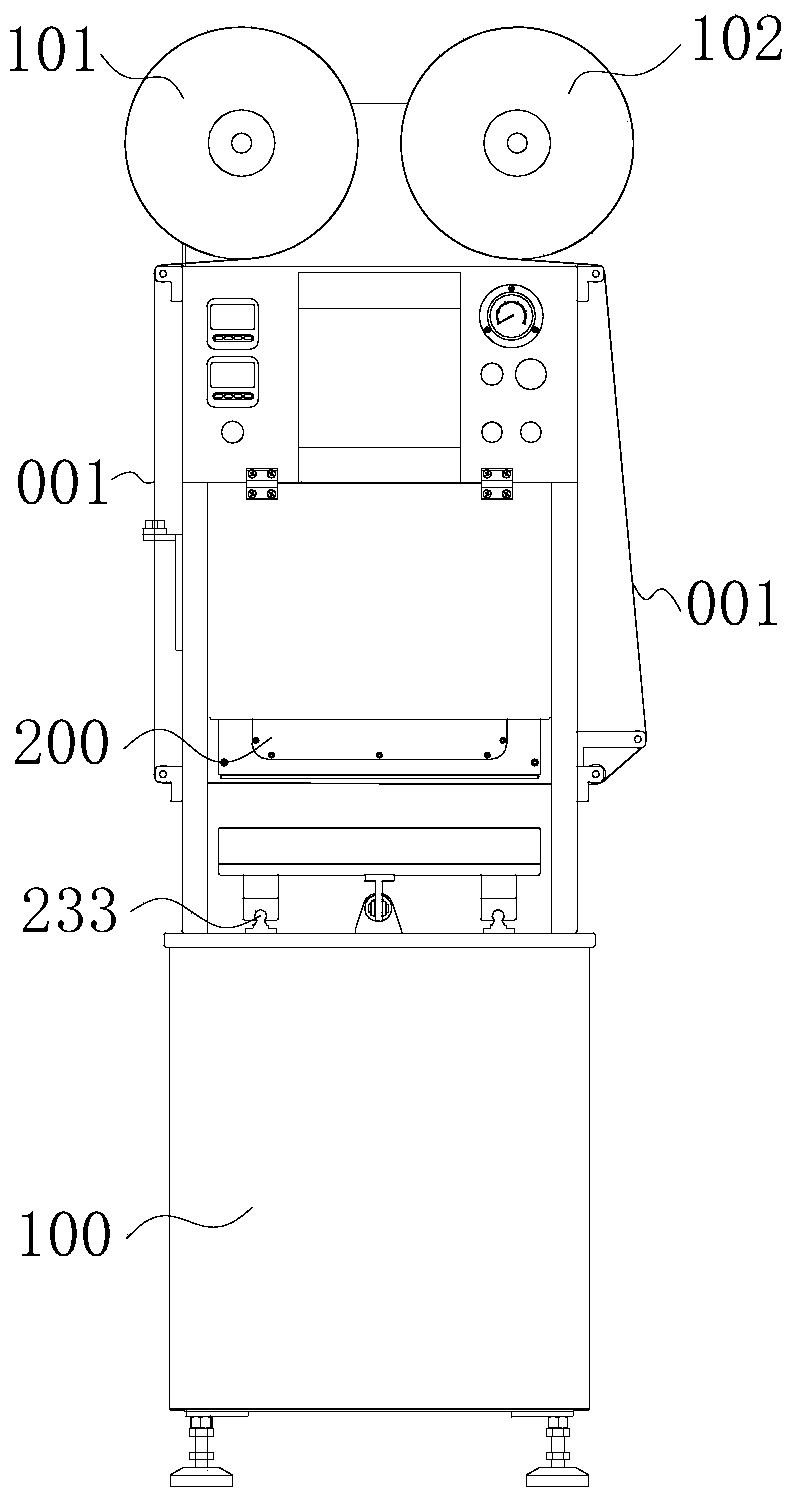

Modified atmosphere packaging machine

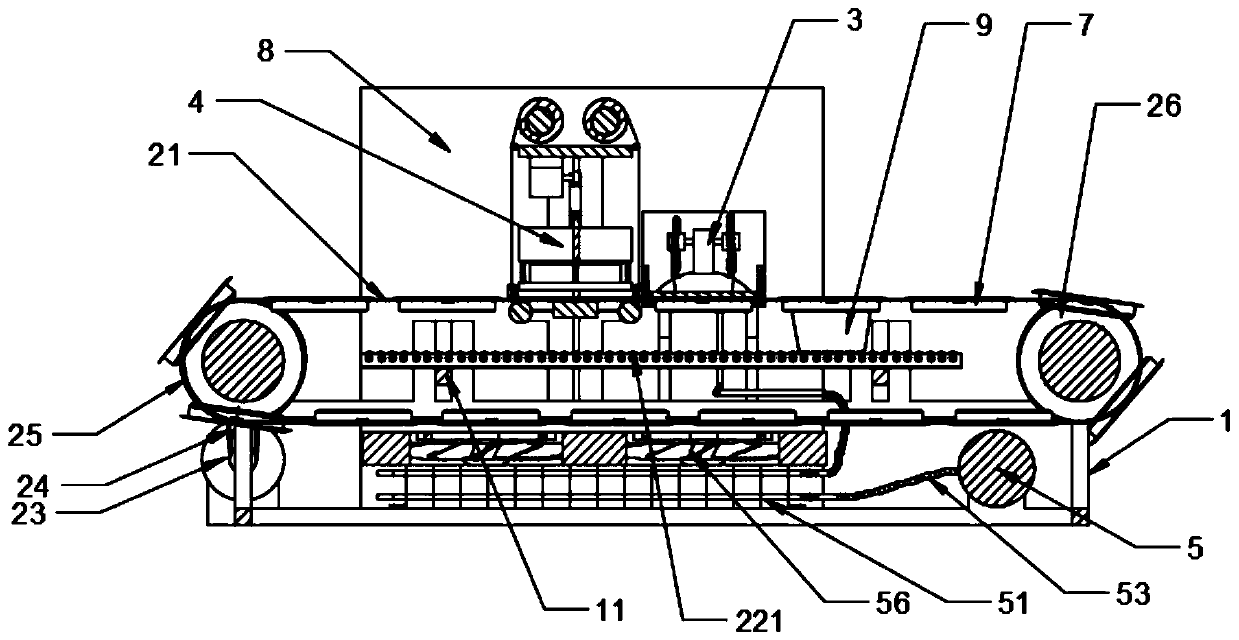

InactiveCN105599976ALow costSave electricityPackaging under vacuum/special atmosphereModified atmosphereProduct gas

The invention particularly relates to a modified atmosphere packaging machine, and aims to provide a modified atmosphere packaging machine which has the advantages of effectively lowering of the cost and convenience in use. The modified atmosphere packaging machine comprises a frame, wherein the frame is provided with a packaging barrel and a recovering barrel; the packaging barrel is wound with a packaging film; a module assembly is arranged on the frame and below the packaging barrel; an upper vacuum chamber and a lower vacuum chamber are isolated into two independent enclosed cavities. When a packaging box is inflated, refreshment gas can only be charged into the lower vacuum chamber, and air is charged into the upper vacuum chamber, so that a large amount of refreshment gas is saved, and cost for transporting the refreshment gas is saved; meanwhile, the electric power, the labor force and the like consumed by producing the refreshment gas in a gas station are saved.

Owner:上海福帝包装机械有限公司

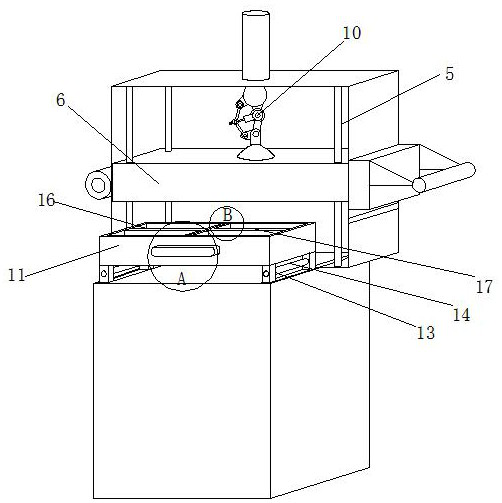

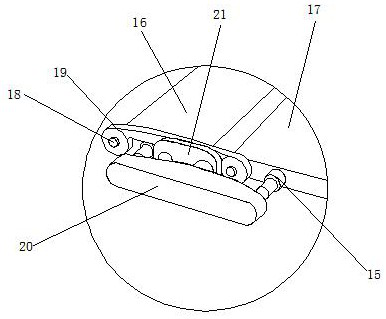

Continuous modified atmosphere fresh-keeping packaging machine and packaging method thereof

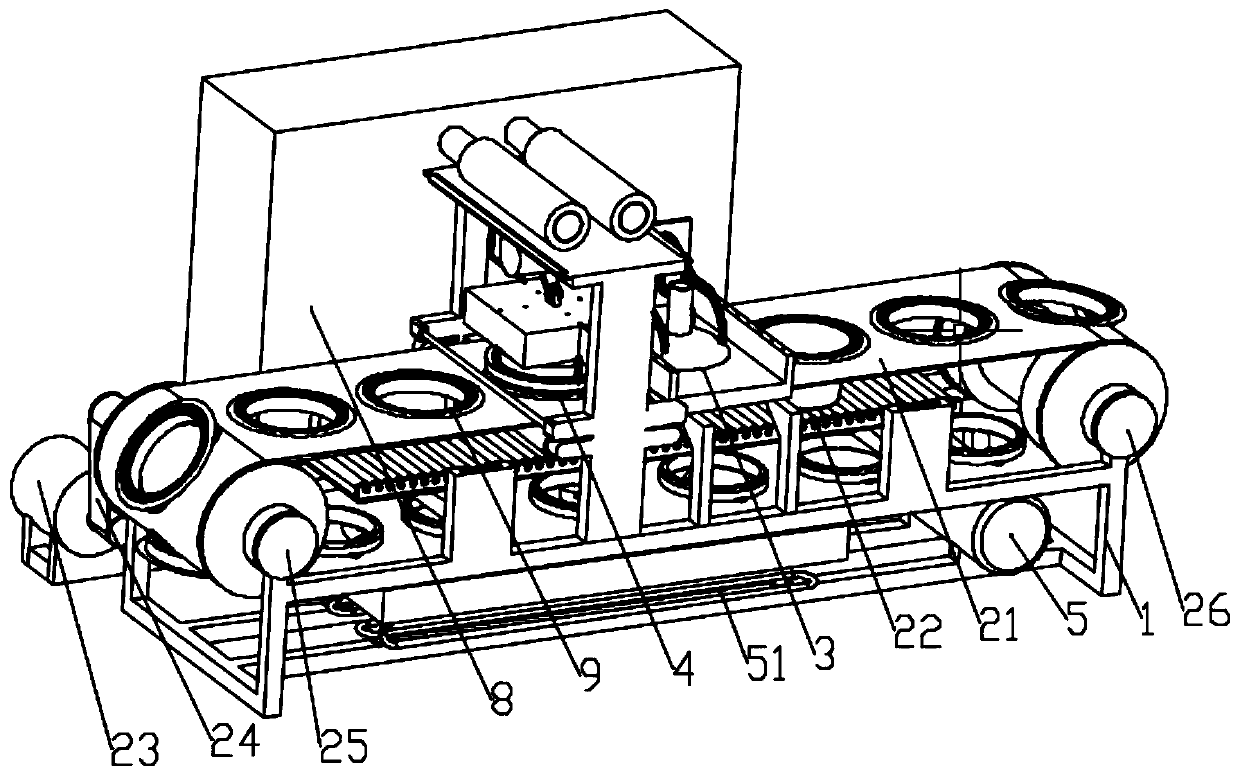

PendingCN110525720AFully automatedImprove work efficiencyPackaging by pressurising/gasifyingModified atmosphereEngineering

The invention discloses a continuous modified atmosphere fresh-keeping packaging machine and a packaging method thereof. The packaging machine comprises a conveying mechanism, an atmosphere modification mechanism and a sealing and cutting mechanism which are arranged on a rack; at least four stations are arranged on a containing opening conveying belt and synchronously conduct feeding, atmospheremodification, sealing and cutting and discharging procedures respectively; packaging containers are placed in the containing opening stations, and a containing opening bearing mechanism is borne at the lower ends of the containing opening packaging containers. The containing opening atmosphere modification mechanism comprises an atmosphere modification chamber main body; the containing opening atmosphere modification chamber main body and the conveying face of the containing opening conveying belt are elastically sealed, a dynamic sealing space is formed above the conveying belt, the atmosphere modification chamber main body is connected with an inflation mechanism, the inflation mechanism sprays nitrogen to the containing opening packaging containers, an exhaust channel is formed in the atmosphere modification chamber main body, and an oxygen sensor for monitoring the oxygen concentration is installed on the inner wall of the containing opening exhaust channel. The dynamic sealing space can effectively prevent space gaps caused by station transfer from influencing air tightness, and the oxygen sensor monitors the oxygen content in exhausted gas to prevent a large amount of oxygenfrom remaining in the packaging container.

Owner:ZHONGKAI UNIV OF AGRI & ENG

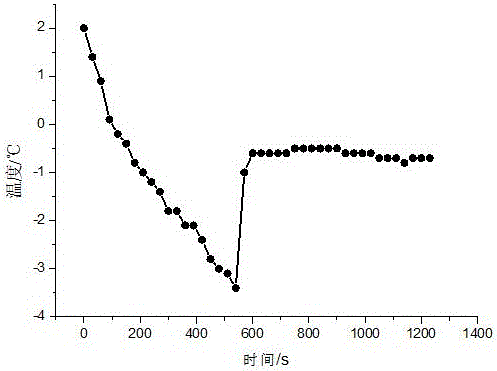

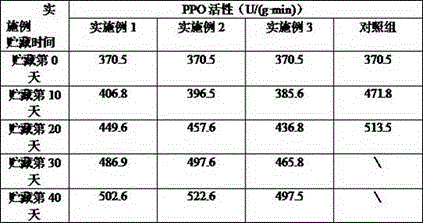

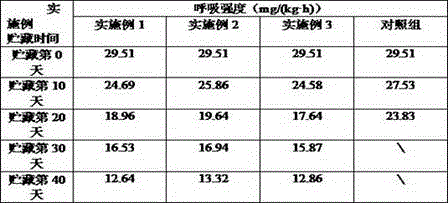

Fresh-keeping method of toona sinensis sprouts based on ice-temperature storage

InactiveCN106472658AAvoid damageIncrease resistanceFruits/vegetable preservation by freezing/coolingMembrane lipidsAir conditioning

The invention relates to a fresh-keeping method of toona sinensis sprouts based on ice-temperature storage. The fresh-keeping method comprises the following steps of (1) collecting toona sinensis sprouts; (2) performing fresh keeping with a biological fresh-keeping agent and performing precooling; (3) performing spontaneous air-conditioning fresh-keeping packaging; (4) determining the temperature of ice temperature; and (5) performing ice-temperature preservation. According to the fresh-keeping method disclosed by the invention, internal nutrient components and external organoleptic quality of the toona sinensis sprouts are maintained to the great extent, and the breathe intensity and the lipid peroxidation degree of the toona sinensis sprouts are reduced. Besides, the activity of polyphenol oxidase PPO is restrained, the shelf life can be prolonged to about 40 days, and the purposes of storage and fresh keeping are achieved. The fresh-keeping technology is simple, convenient to operate, easy to implement, low in cost, environment-friendly, free from toxic effects on human bodies, and broad in market prospects.

Owner:HENAN ACAD OF AGRI SCI

Leisure duck tongue and making method thereof

InactiveCN106036518AIncrease added valueUnique fragranceClimate change adaptationFood scienceBiotechnologyCooking & baking

The invention relates to the technical field of food processing and discloses leisure duck tongue and a making method thereof. The leisure duck of the invention is elastic, crispy, chewy, uniquely-flavored, fresh and delicious leisure duck tongue with significantly prolonged shelf life made by: pickling, normal-pressure hot blast drying, marinating, baking, cooling and controlled atmosphere preservative packaging. The marinated duck tongue is innovatively subjected to controlled atmosphere preservative packaging, a making process need no vacuum packaging and high-temperature sterilization, on one hand, nutrients of duck tongue are well retained and the shelf life of a product is prolonged, and the other hand, a production cycle is shortened and production cost is reduced; the provided leisure duck tongue is simple to make, an obtained product has unique flavor, original flavor and nutrition of raw material of the product are maximally retained, a high-quality food with rich nutrition and high cost performance is provided for people at the premise that added value of the duck tongue is improved, and the obtained food has good popularization and market value.

Owner:湖南唐人神肉制品有限公司

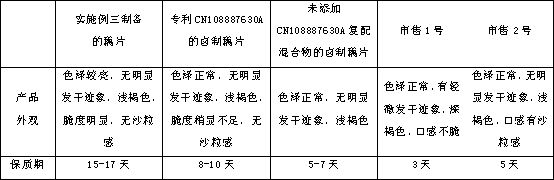

Method for preparing marinated lotus root slices

InactiveCN108887630ARich tasteGood colorFruit and vegetables preservationClimate change adaptationBiotechnologyModified atmosphere

The invention discloses a method for preparing marinated lotus root slices. The method comprises the following steps: cleaning, marinating, cooling, slicing, modified atmosphere packaging, packing andthe like. The invention provides a complete processing method for lotus root slices. The marinating soup for the marinated lotus root slices adopts residual marinating soup after marinating geese, sothat decoction of soup-stock is avoided, and time is saved. Meanwhile, the residual marinating soup is fully utilized, waste is reduced, and the processed and prepared lotus root slices are rich in taste and excellent in color. Moreover, a unique complex mixture is added during marinating and forms interaction with components in the marinade, an antibacterial system which is high in penetration and stable is formed, the quality guarantee period is prolonged, and the method has obvious competitive advantages in the market.

Owner:江苏你好鸭食品有限公司

Method for preparing marinated bean curds

InactiveCN108887399ATake advantage ofRich tasteCheese manufactureFood scienceAdditive ingredientThermal expansion

The invention discloses a method for preparing marinated bean curds. The method comprises the following steps: cleaning, marinating, cooling, soaking at a low temperature, slicing, modified atmospherepackaging, packing and the like. With the adoption of the low-temperature soaking and flavoring process, secondary flavoring of the bean curds is facilitated, the bean curds are not subjected to thermal expansion and cold contraction after low-temperature flavoring, marinade remains in the bean curds and does not seep, and the problem that the interior of the bean curds is difficult to be flavored is solved. A unique complex mixture is added during marinating and forms interaction with components in the marinade, the quality guarantee period further reaches 10-12 days, and the method has obvious competitive advantages in the market.

Owner:江苏你好鸭食品有限公司

Modified atmosphere packaging method for fructus lycii

InactiveCN105994594AImprove toughnessPrevent oxidationFruits/vegetable preservation by irradiation/electric treatmentSacksModified atmosphereMoisture absorption

The invention provides a modified atmosphere packaging method for fructus lycii, and belongs to the field of food fresh-keeping. The modified atmosphere packaging method is mainly comprises the following steps: a, packaging fructus lycii, wherein a packaging bag is a composite membrane bag formed by compounding a kraft paper layer, an aluminum foil layer and a polyethylene layer; b, filling the packaging bag with mixed gas, wherein the mixed gas contains 95%-97% of N2 and 3%-5% of CO2; c, adopting <60>Co-gamma for radiation treatment; therefore, the modified atmosphere packaging method provided by the invention for fructus lycii is safe, efficient and long in storing time, and effectively prevents fructus lycii from moisture absorption and agglomeration, and oxidation discoloration.

Owner:精河县果康枸杞葡萄种植专业合作社

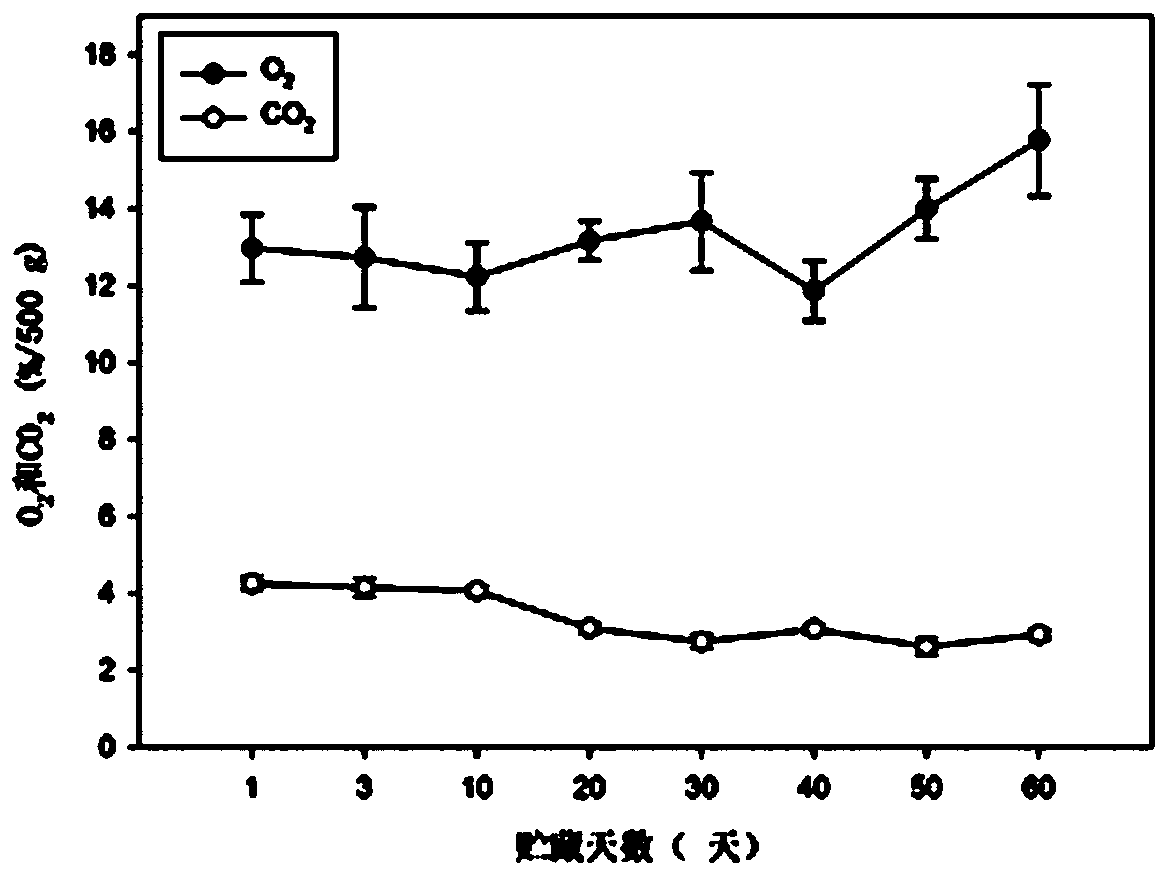

Gas-filled packaging method for retaining freshness of cherries

InactiveCN102485608AProtect antibacterial ingredientsInhibition of growth and reproductionFruit and vegetables preservationContainers preventing decayNitrogenOxygen

The invention relates to the technical field of package and in particular relates to a gas-filled packaging method for retaining the freshness of cherries. According to the invention, a composite controlled-atmosphere packaging method is adopted, wherein air in a packaging box or packaging bag is replaced; the packaging box or packaging bag is made from a low-barrier film; and the controlled-atmosphere gas consists of 5-8% carbon dioxide (CO2), 82-87% nitrogen (N2) and 8-10% oxygen (O2). The packaging box or packaging bag is sealed after air in the packaging box or packaging bag is replaced, and then stored at a temperature of 0-4 DEG C. The gas replacing rate is over 99.8%, and the error rate of the freshness retaining gas mixing accuracy is less than 1.5%.

Owner:大连渴望科技发展有限公司

Fresh keeping method of chilled chicken and composite preservative liquid

InactiveCN110024842AExtend sales distanceGuarantee nutritional qualityMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsIce waterNutritional quality

The invention provides a fresh keeping method of a chilled chicken. The fresh keeping method comprises the following steps of (1) preparing composite preservative liquid; (2) putting a fresh broiler which is subjected to slaughter treatment in ice water mixed liquid, performing cooling, performing draining to obtain a chilled chicken, and putting the chilled chicken in the composite preservative liquid prepared in the step (1) for soaking; and (3) performing modified atmosphere fresh keeping packaging on the soaked chicken and an ice bag together, and then performing logistics distribution under the condition of refrigeration or normal temperature. The fresh keeping method of the chilled chicken disclosed by the invention integrates a chemical preservative technique and a modified atmosphere fresh keeping technique, and the adopted chemical preservative agent is composite preservative dried orange peel extraction liquid; and under normal temperature, the storage period of the chilled chicken treated by the method reaches 2-3 days, so that the sale distance of the chilled chicken under express delivery transportation under the condition of normal temperature is extended, and the nutritional quality of chicken meat is guaranteed.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

A Modified Atmosphere Fresh-keeping Packaging Machine

InactiveCN105599976BLow costSave electricityPackaging under vacuum/special atmosphereEngineeringModified atmosphere

The invention particularly relates to a modified atmosphere packaging machine, and aims to provide a modified atmosphere packaging machine which has the advantages of effectively lowering of the cost and convenience in use. The modified atmosphere packaging machine comprises a frame, wherein the frame is provided with a packaging barrel and a recovering barrel; the packaging barrel is wound with a packaging film; a module assembly is arranged on the frame and below the packaging barrel; an upper vacuum chamber and a lower vacuum chamber are isolated into two independent enclosed cavities. When a packaging box is inflated, refreshment gas can only be charged into the lower vacuum chamber, and air is charged into the upper vacuum chamber, so that a large amount of refreshment gas is saved, and cost for transporting the refreshment gas is saved; meanwhile, the electric power, the labor force and the like consumed by producing the refreshment gas in a gas station are saved.

Owner:上海福帝包装机械有限公司

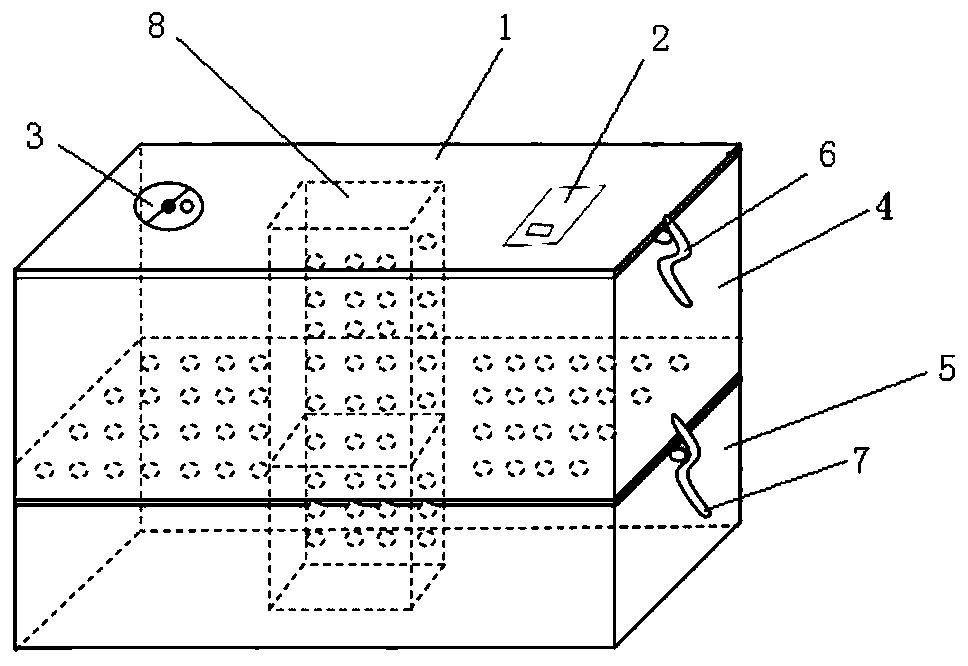

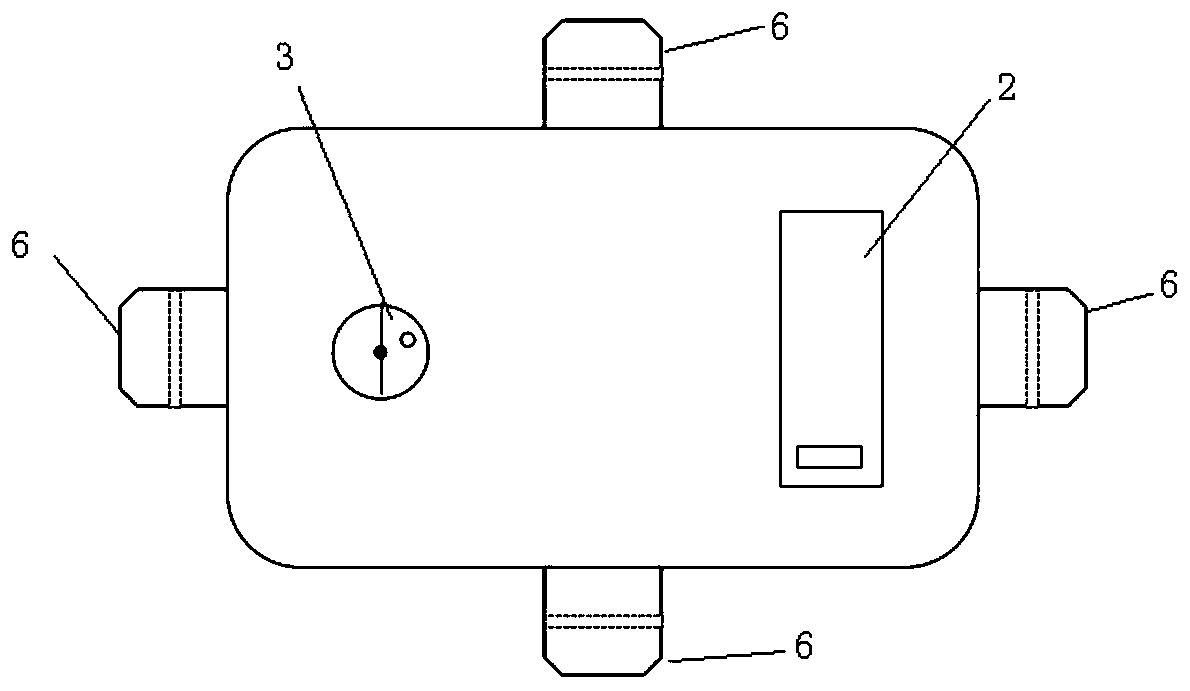

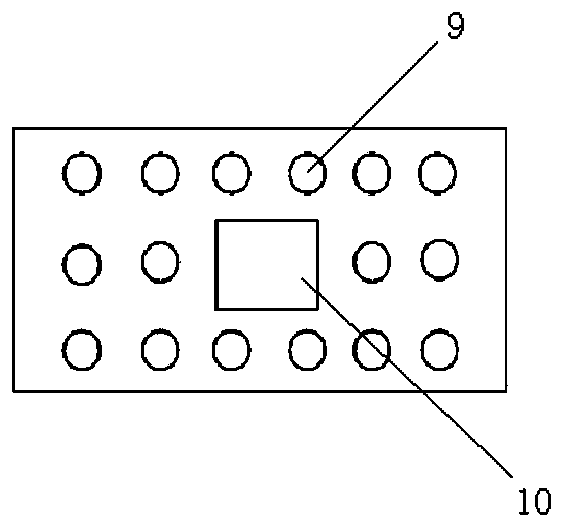

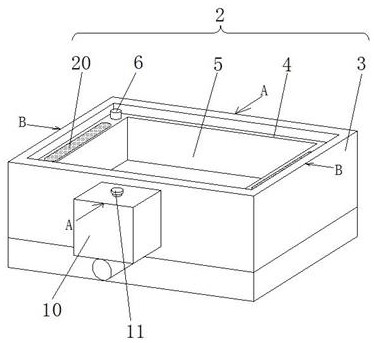

Controlled atmosphere fresh-keeping packaging box for fresh-cut fruits or vegetables

InactiveCN110077715AEasy to carry and transportEasy to operateClosure with auxillary devicesContainers preventing decayAnaerobic respirationWater storage

The invention discloses a controlled atmosphere fresh-keeping packaging box for fresh-cut fruits or vegetables, and belongs to the field of fruit and vegetable fresh-keeping packaging. The packaging box consists of three parts, specifically, a box cover, a storage box and a water storage box, wherein a controlled atmosphere hole and a groove with a cover are formed in the box cover, draining through holes are formed in the bottom surface of the storage box, a preservative storage cavity is formed in the vertical direction, and fresh-keeping vent holes are formed in the surface of the preservative storage cavity. According to the packaging box, the gas environment in the box is effectively controlled through the controlled atmosphere hole in the box cover, so that the quality of the fruit and vegetable is reduced caused by excessive anaerobic respiration is avoided, the bottom of the box is connected to the detachable preservative storage cavity, the preservative agent gas is uniformlyreleased through through holes in four walls of the cavity to inhibit the physiological activity and mildew rot of the fresh-cut fruits and vegetables, and a box body is arranged to store water so asto keep certain humidity in the box, and the shelf life of the fresh-cut fruits and vegetables is prolonged.

Owner:DALIAN NATIONALITIES UNIVERSITY

Modified atmosphere fresh-keeping package for meat products

InactiveCN112623462APackaging under vacuum/special atmosphereContainers preventing decayProcess engineeringModified atmosphere

A modified atmosphere fresh-keeping package for meat products is used for modified atmosphere fresh-keeping of cooked meat or fresh meat and comprises a package box body used for introducing modified atmosphere fresh-keeping gas, and a cover film; the packaging box body is provided with a first space and a second space; the cover film is used for sealing the packaging box body; the pressure intensity of the modified atmosphere fresh-keeping gas in the packaging box body is greater than the atmospheric pressure intensity; the first space is used for placing meat products; a compressed air bag is arranged in the second space and is fixed at the bottom of the second space; and the bottom or the side wall of the second space is provided with a size mark corresponding to the compressed air bag, and whether gas leakage exists in the modified atmosphere fresh-keeping package of the meat products or not can be judged according to the size mark of the compressed air bag.

Owner:王瑞雪

Processing and storing method for prolonging shelf life of marinated beef

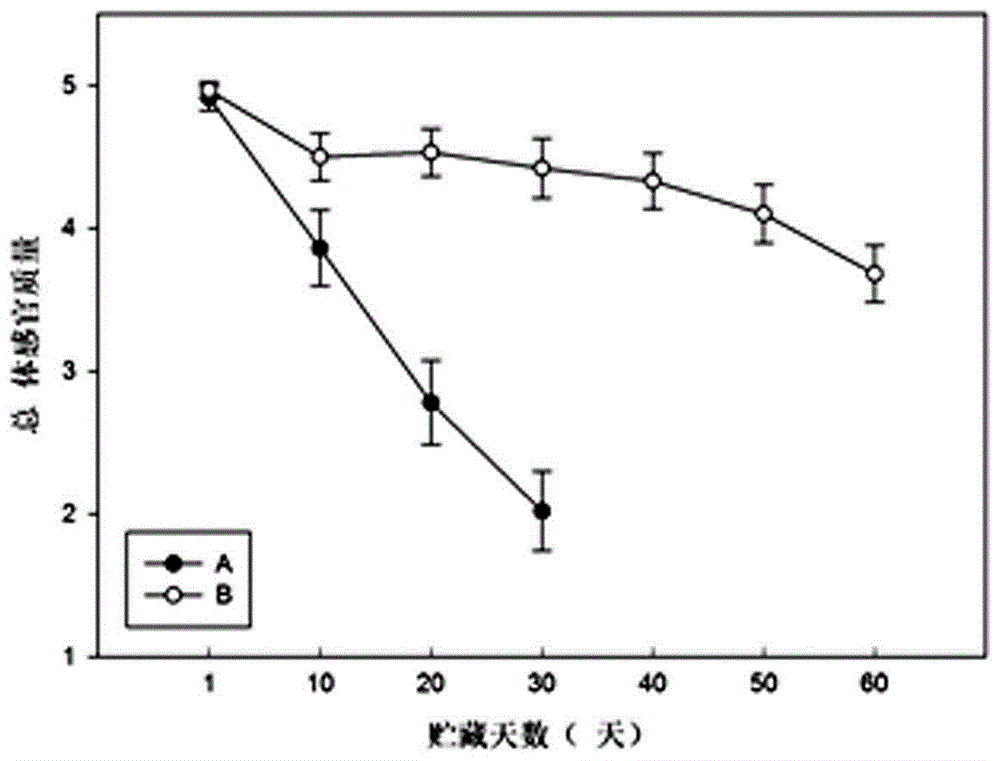

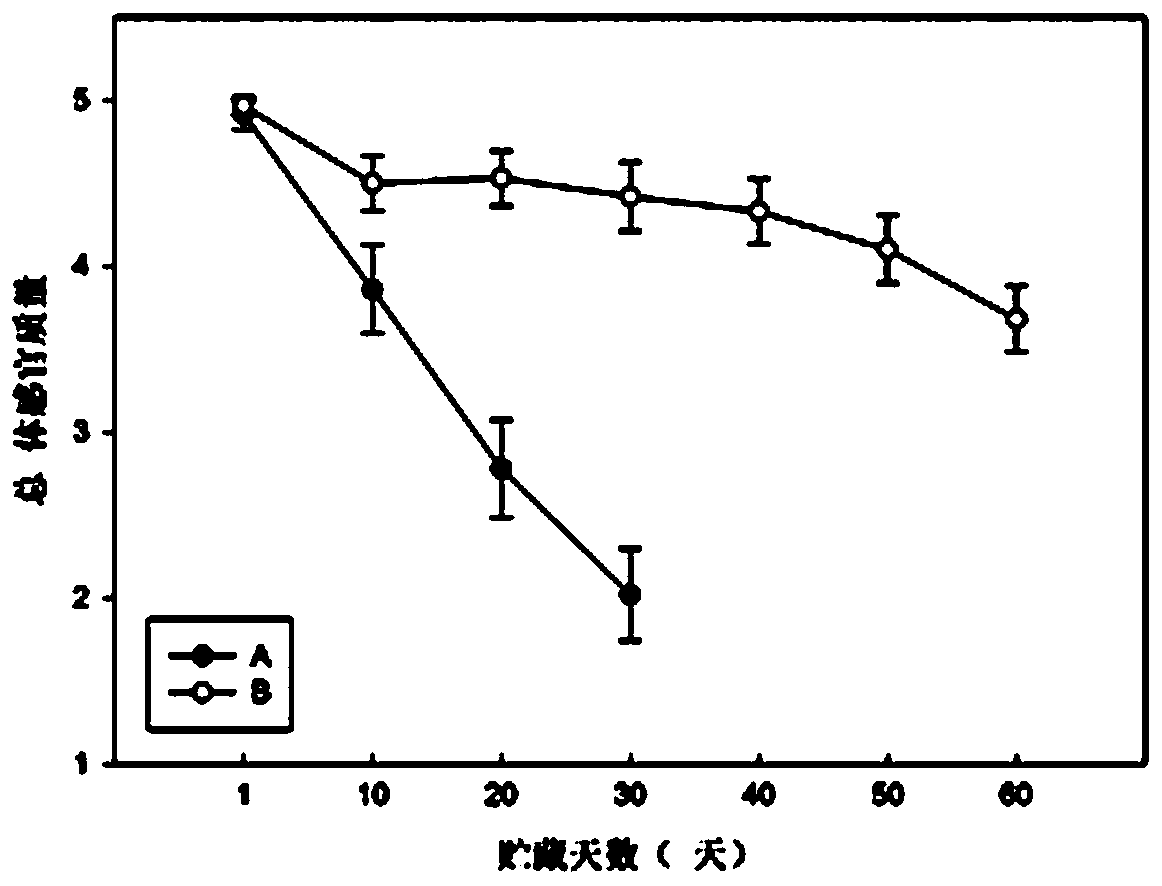

PendingCN112167313AHigh average scoreGreat tasteFood freezingGaseous food ingredientsPreservativeEngineering

The invention discloses a processing and storing method for prolonging the shelf life of marinated beef. The processing and storing method comprises the following steps: preparing a fresh-keeping agent; adding the fresh-keeping agent, and soaking the marinated beef; performing modified atmosphere fresh-keeping packaging; and storing and the like. The shelf life of the marinated beef produced by adopting the method can reach 7-8 days under the condition that no preservative is added.

Owner:江苏五香居食品有限公司

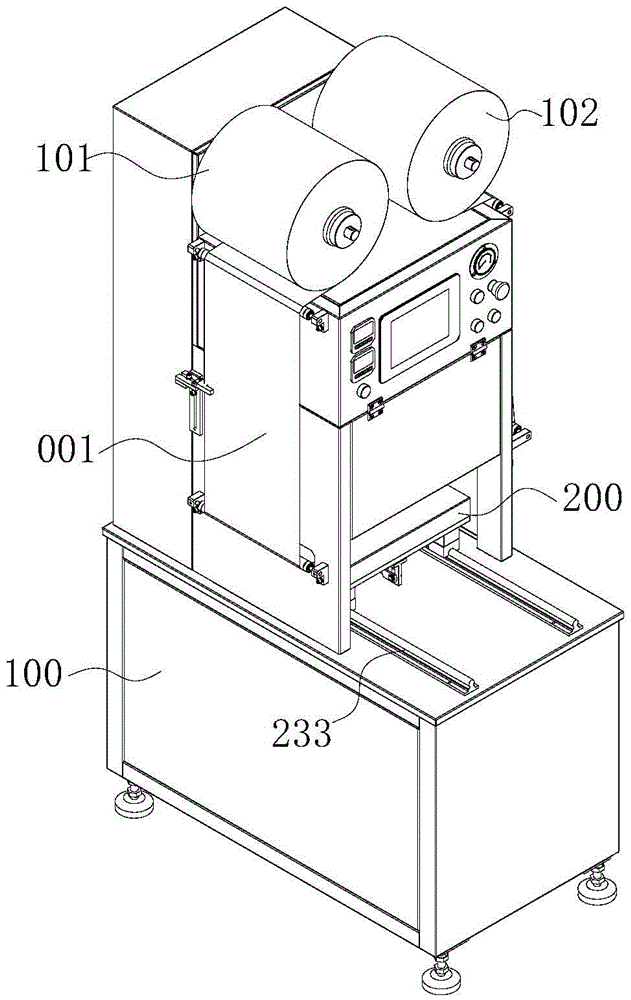

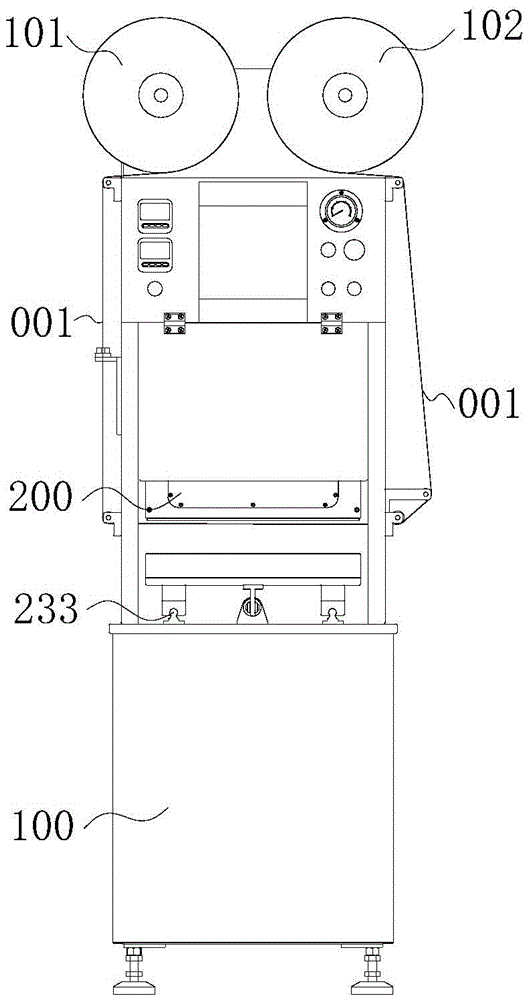

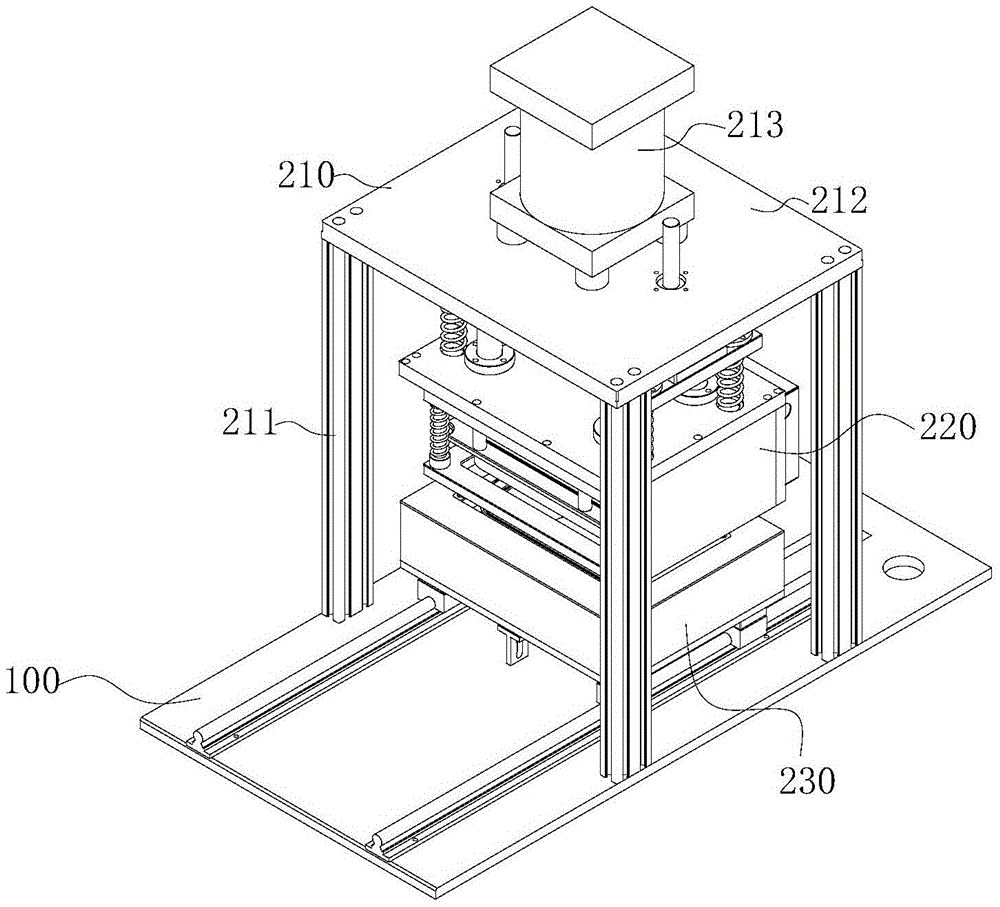

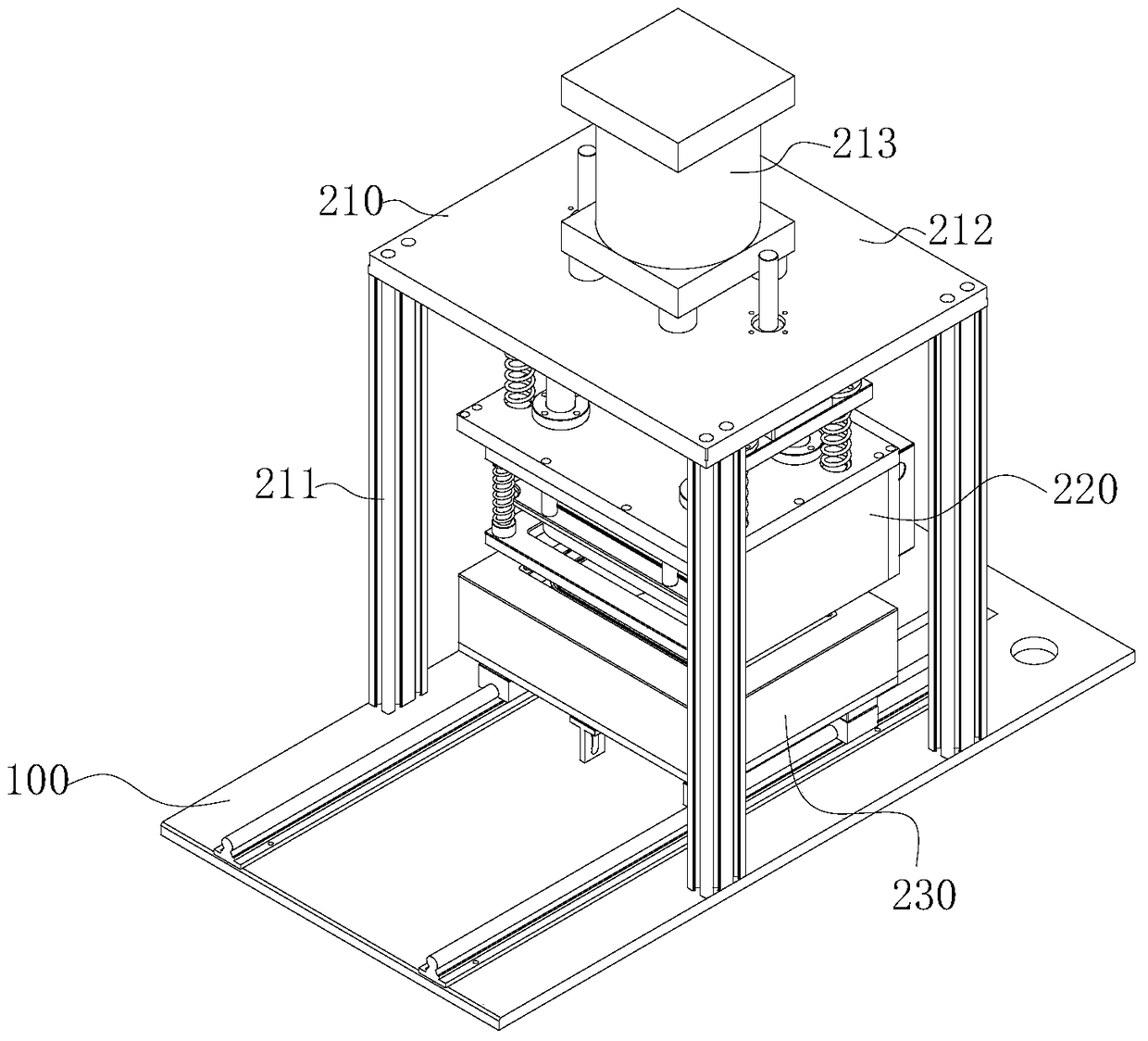

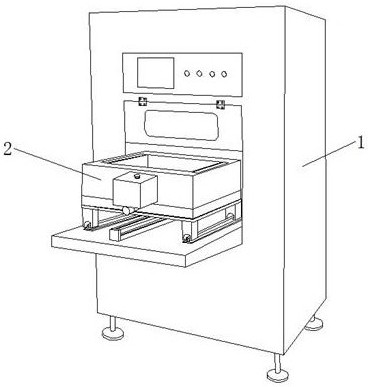

Cutting and sealing structure of full-automatic modified atmosphere fresh-keeping packaging machine

ActiveCN113493028AFast cutting speedEasy to unloadWrapper twisting/gatheringEngineeringModified atmosphere

The invention discloses a cutting and sealing structure of a full-automatic modified atmosphere fresh-keeping packaging machine. The cutting and sealing structure comprises a supporting table, an operation box is arranged above the supporting table, sliding ways are arranged at the left end and the right end of the upper portion of the supporting table, a lower module is arranged on the sliding ways, sliding rods are arranged at the four corners inside the operation box, an overload protection device is arranged, when a hydraulic rod is started to enable an upper module to press a lower die downwards and the downward pressing force is larger than the elasticity of springs, the included angle between a V-shaped rod and a protruding block is decreased, a third bearing is pushed to slide leftwards on an ejector rod, the springs are compressed, it is guaranteed that overlarge pressure generated when the lower module is pressed downwards by the upper module is subjected to overload protection, the module is prevented from being damaged, and the springs with different elasticity can be replaced according to the materials of the corners of a packaging box, the downward pressing force of the upper module is changed, and the situation that the corners of the packaging box are damaged due to the excessive pressure of the upper module is prevented.

Owner:上海帆铭机械有限公司

Standardized processing method for improving food safety level of fruit and vegetable instant dishes

PendingCN113892605AImprove food safetyReduce processing timeClimate change adaptationFood preservationBiotechnologyFood safety

The invention discloses a standardized processing method for improving the food safety level of fruit and vegetable instant dishes. The standardized processing method comprises the following processing steps of: cleaning and selecting fruits and vegetables, performing primary protection, marinating, performing primary cooling, performing secondary protection, performing secondary cooling, slicing and trimming, and performing modified atmosphere packaging. Aiming at the characteristics of the fruit and vegetable instant dishes, the invention provides the corresponding standardized processing method for the fruit and vegetable instant dishes, and each processing procedure is naturally linked, so that the processing time is saved, the working efficiency is improved, and artificial participation is reduced as much as possible, so that the risk of artificial pollution in each link is reduced, and the food safety level of the fruit and vegetable instant dishes is comprehensively improved.

Owner:江苏你好鸭食品有限公司

Modified atmosphere fresh-keeping packaging machine with oxygen consumption type secondary deoxidizing structure

PendingCN113493030ATo remove oxygenGood fresh-keeping effectPackaging under vacuum/special atmospherePackaging automatic controlEnvironmental engineeringModified atmosphere/modified humidity packaging

The invention discloses a modified atmosphere fresh-keeping packaging machine with an oxygen consumption type secondary deoxidizing structure, which comprises a modified atmosphere packaging machine main body, a lower module is slidably arranged in the middle of the modified atmosphere packaging machine main body, the lower module comprises an outer shell, an inner shell is fixedly mounted in the outer shell, and a containing cavity is formed in the inner shell; an oxygen detection sensor is fixedly installed at the top corner of one end of the upper surface of the inner shell, a cavity is formed between the inner shell and the outer shell, a circulating deoxidizing mechanism is fixedly installed in the cavity, and a waste collecting box installed on the lower wall of the outer shell is arranged under the middle position of the circulating deoxidizing mechanism; and a deoxidizing material box is fixedly mounted in the middle of one side wall of the outer shell. According to the modified atmosphere fresh-keeping packaging machine, the purpose of deoxidizing can be achieved through chemical reaction between deoxidizing substances and oxygen, and automatic feeding of the deoxidizing substances, automatic flowing of air in the circulating deoxidizing mechanism and automatic discharging of waste obtained after deoxidizing reaction can be achieved.

Owner:上海帆铭机械有限公司

Modified atmosphere preservation technology of tussah food

InactiveCN109452345AScientific and reasonable processEasy to makeMeat/fish preservation by heatingGaseous food ingredientsFood gradeRoom temperature

The present invention relates to a modified atmosphere preservation technology of tussah food. The modified atmosphere preservation technology of the tussah food is characterized by comprising the following steps: material selecting is conducted: fresh tussah larvae, tussah pupae, tussah tender pupae or tussah moths are prepared; packaging is conducted: the selected tussah larvae, tussah pupae, tussah tender pupae or tussah moths are subjected to modified atmosphere preservation packaging and packaging bags should be selected with food-grade packaging bags with at least 3 layers of composite high-gas barriers and filled gas is nitrogen and carbon dioxide gas; and sterilizing is conducted: the packaged tussah larvae, tussah pupae, tussah tender pupae or tussah moths are placed in a counter-pressure high-temperature sterilization pot for the sterilizing, after set sterilizing time is completed, counter-pressure temperature-lowering begins, so that the manufactured tussah larva, tussah pupa, tussah tender pupa or tussah moth food does not break the bags, and the tussah food in the bags can maintain original shape, does not produce water, is free of deformation and good in eating mouthfeel, and can be stored at room temperature for 3 months and cold-stored for 6 months. The manufactured modified atmosphere preserved and packaged tussah food can be eaten once the bags are opened andcan also be used for eating methods of stir-frying, oil-frying, grilling, etc.

Owner:JILIN SERICULTURE SCI RES INST

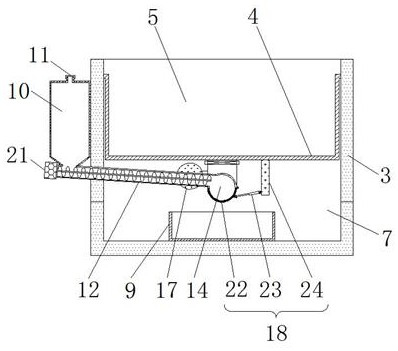

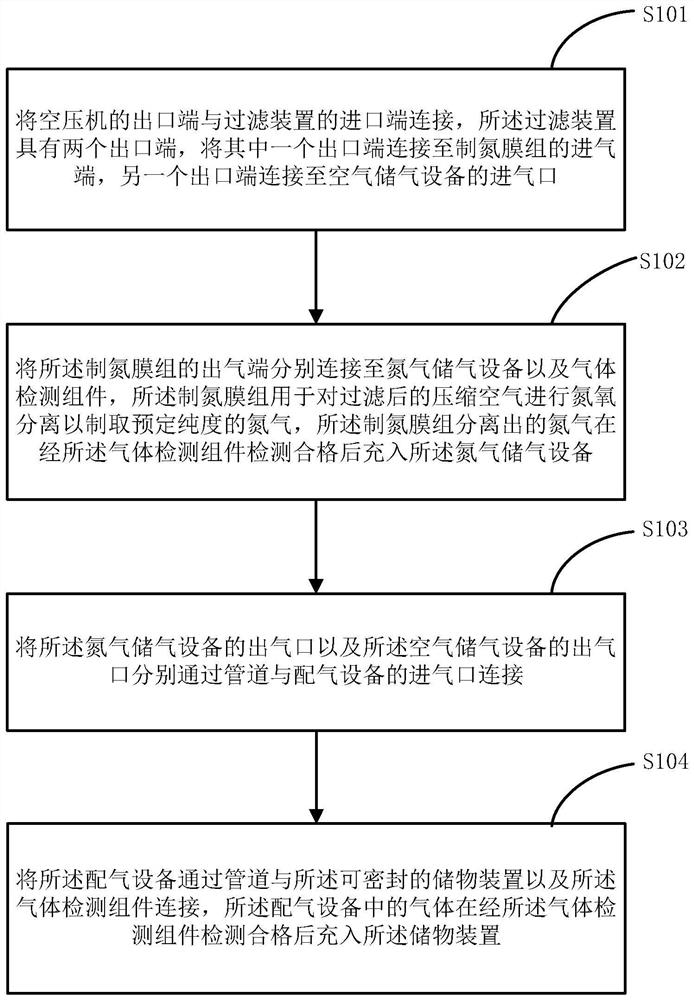

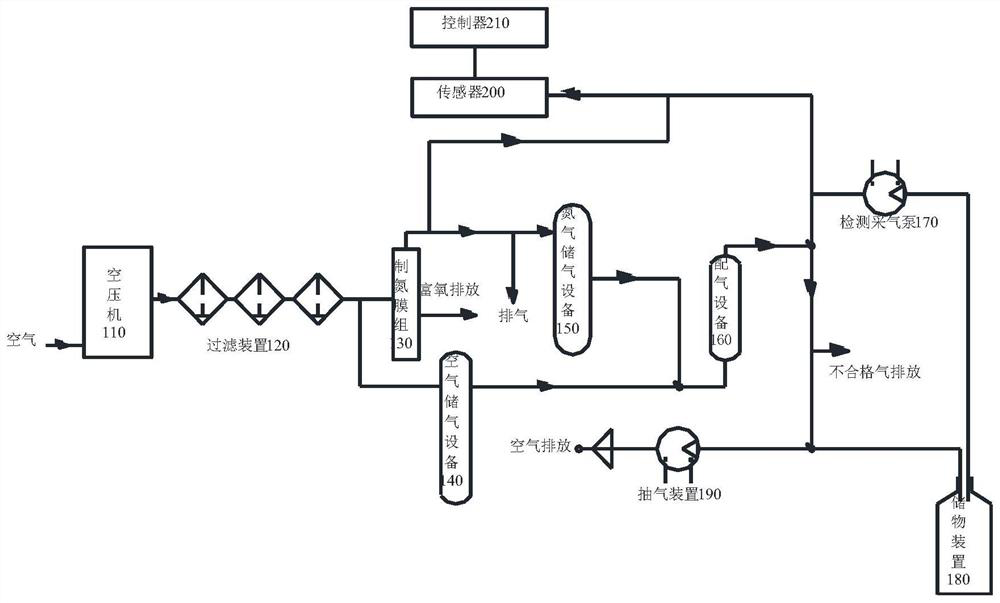

Design method and device of modified atmosphere fresh-keeping packaging auxiliary device

PendingCN114275373AAvoid dependenceSolve the problem of poor fresh-keeping effectPackaging under vacuum/special atmospherePackaging fruits/vegetablesProcess engineeringEnvironmental engineering

The invention relates to a design method and device of an air-conditioning fresh-keeping packaging auxiliary device. The method comprises the steps that an air compressor is connected with the filtering device, the outlet end of the filtering device is connected with the nitrogen making membrane set and the air storage equipment, and the air outlet end of the nitrogen making membrane set is connected to the nitrogen storage equipment and the gas detection assembly; the nitrogen storage equipment and the air storage equipment are respectively connected with the gas distribution equipment through pipelines; the gas distribution equipment is connected with the sealable storage device and the gas detection assembly through pipelines; the modified atmosphere packaging auxiliary device can be designed by the aid of the modified atmosphere packaging auxiliary device. The modified atmosphere fresh-keeping device can conveniently realize modified atmosphere fresh-keeping.

Owner:TIANJIN CNRO SCI TECH

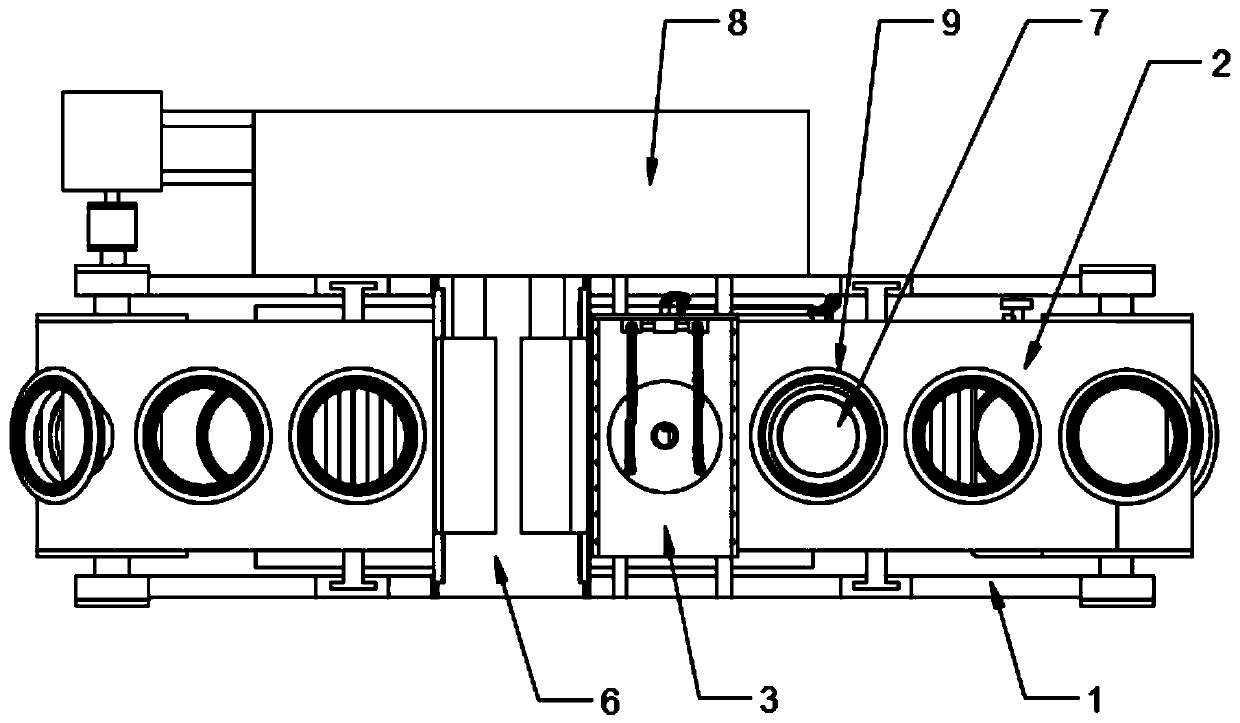

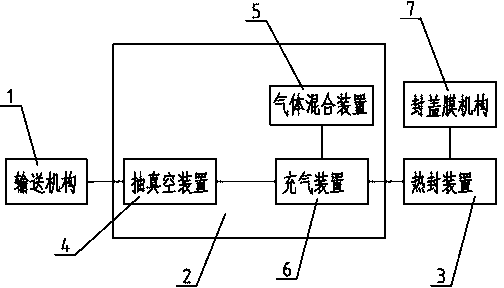

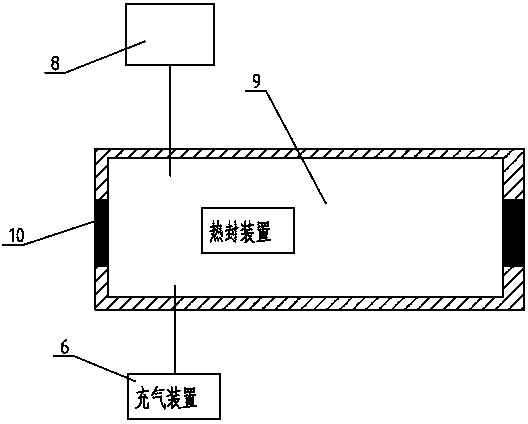

Modified atmosphere fresh-keeping packaging machine

InactiveCN103538746AAvoid gas poisoning and other injuriesAvoid harmPackaging under vacuum/special atmosphereShielding gasModified atmosphere

The invention relates to a modified atmosphere fresh-keeping packaging machine which comprises a conveying mechanism, an air interchanger and a heat-seal device. The air interchanger comprises a vacuumizing device, a gas mixing device and an inflating device. The conveying mechanism is connected with the air interchanger and the heat-seal device. The vacuumizing device is arranged in front of the inflating device. The gas mixing device is connected with the inflating device to supply protective gas for the inflating device. The modified atmosphere fresh-keeping packaging machine further comprises a cap-sealing membrane mechanism used for supplying cap-sealing membranes for the heat-seal device. According to the modified atmosphere fresh-keeping packaging machine, a totally-closed vacuum chamber gas displacement technology is adopted, the high gas displacement rate can be guaranteed, the content of residual oxygen in a packaging box can reach the minimum, the mixing accuracy of composite gas in a packaging tray can be guaranteed effectively, and the fresh-keeping effect is better.

Owner:ZHENJIANG YUANCHUN MEAT PRODS

Preparation method of cooked lotus root slices with long shelf life

PendingCN113892607AHigh sensory evaluationImprove crispnessFood ingredient as antioxidantFruit and vegetables preservationBiotechnologyEngineering

The invention discloses a preparation method of cooked lotus root slices with a long shelf life. The preparation method comprises the processing steps of cleaning, Brasenia schreberi J. F. Gmel. processing, marinating, cooling, post-protecting, slicing and modified atmosphere fresh-keeping packaging. On the basis of the prior art, application of the Brasenia schreberi J. F. Gmel. serving as a natural plant protection function in preparation of the lotus root slices is provided, an unexpected effect is achieved, and the shelf life reaches 15-17 days.

Owner:江苏你好鸭食品有限公司

Controlled-atmosphere fresh-keeping packing method for honey peaches

InactiveCN107969476AConditions are easy to achieveSuitable for mass productionFruits/vegetable preservation by irradiation/electric treatmentGaseous food ingredientsNitrogenModified atmosphere/modified humidity packaging

The invention relates to the technical field of fresh-keeping packaging, in particular to a controlled-atmosphere fresh-keeping packing method for honey peaches. The method comprises the following steps: step 1, selecting materials; step 2, conducting cleaning and soaking: cleaning honey peaches before preservation, soaking the honey peaches in 1% NaClO solution for 5-10minutes, and then further soaking the honey peaches in a fresh-keeping liquid for 30-50min; step 3, conducting drying; step 4, soaking the dried honey peaches in brine, and airing the soaked honey peaches; and step 5, conducting gas filling and packaging: putting the air-dried honey peaches into a composite fresh-keeping bag filled with an ethylene absorbent, filling the fresh-keeping bag with a barrier gas, and sealing thebag, wherein the barrier gas is a mixture of nitrogen, carbon dioxide and helium. The method can effectively maintain the delicious taste of the honey peaches, has simple implement conditions, is suitable for batch production, has low requirements for storage conditions, and reduces the cost of production and transportation.

Owner:WENZHOU RUNWU E COMMERCE CO LTD

Fresh-keeping method of postharvest broccoli in modified atmosphere packaging

ActiveCN105994593BImprove nutritional qualityGood appearanceFruits/vegetable preservation by freezing/coolingFlavorWater vapor

The invention provides an MAP (modified atmosphere packages) preservation method for picked broccoli. The MAP preservation method comprises the following steps: (1) pretreatment of the picked broccoli: fresh and healthy broccoli without apparent damage is subjected to rapid precooling treatment after picking, and the core temperature is reduced to 0-1 DEG C; (2) preserved MAP: single precooled broccoli or multiple pieces of precooled broccoli are loaded into a polyethylene preservation packaging bag for sealed packaging, the O2 permeability coefficient of the polyethylene preservation packaging bag is 10,000-20,000 cm<3> / m<2>.24h.0.1 MPa, the CO2 permeability coefficient of the polyethylene preservation packaging bag is 6,000-8,000 cm<3> / m<2>.24h.0.1 MPa, and the water vapor transmission of the polyethylene preservation packaging bag is 20-30 g / m<2>.24h; (3) cold storage for preservation: the bagged broccoli subjected to preservation packaging treatment with the polyethylene preservation packaging bag is stored, transported or sold in a cold storage preservation storehouse or a cold storage wagon at the temperature of 0-1 DEG C. The method is simple and convenient to operate, quality deterioration phenomena such as withering and water loss, green fading and yellowing of inflorescence, rot, deterioration and the like of the fresh broccoli after picking can be relieved effectively, special nutrition and flavor of the broccoli in the storage period are kept, the shelf life is prolonged, and popularization and application are easy.

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI +1

Standardized processing method of convenient hairy crab dish

PendingCN114376171AImprove food safetyConnect with natureFood preservationNatural extract food ingredientsEngineeringProcess engineering

The invention discloses a standardized processing method of a convenient hairy crab dish, which comprises the following steps of: selecting fresh and alive hairy crabs produced in a shocklake, cleaning and removing impurities, and putting the hairy crabs into a quick-freezing warehouse for quick-freezing; then marinating in blended sauce, after marinating is completed, performing low-temperature flavoring, and finally performing modified atmosphere fresh-keeping packaging. The convenient hairy crab dish prepared by the method disclosed by the invention has the advantages of high production efficiency, high standardization degree, small pollution risk and long shelf life, and the shelf life can be prolonged by more than 50% on the basis of 3-5 days of the shelf life of the traditional convenient hairy crab dish and can reach 8-10 days.

Owner:江苏你好鸭食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com