A mz type buried scraper sludge conveyor and its method

A conveyor and buried scraper technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as unloading difficulties, production efficiency reduction, maintenance difficulties, etc., to simplify mechanisms and equipment, and reduce land occupation. area, the effect of avoiding the difficulty of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

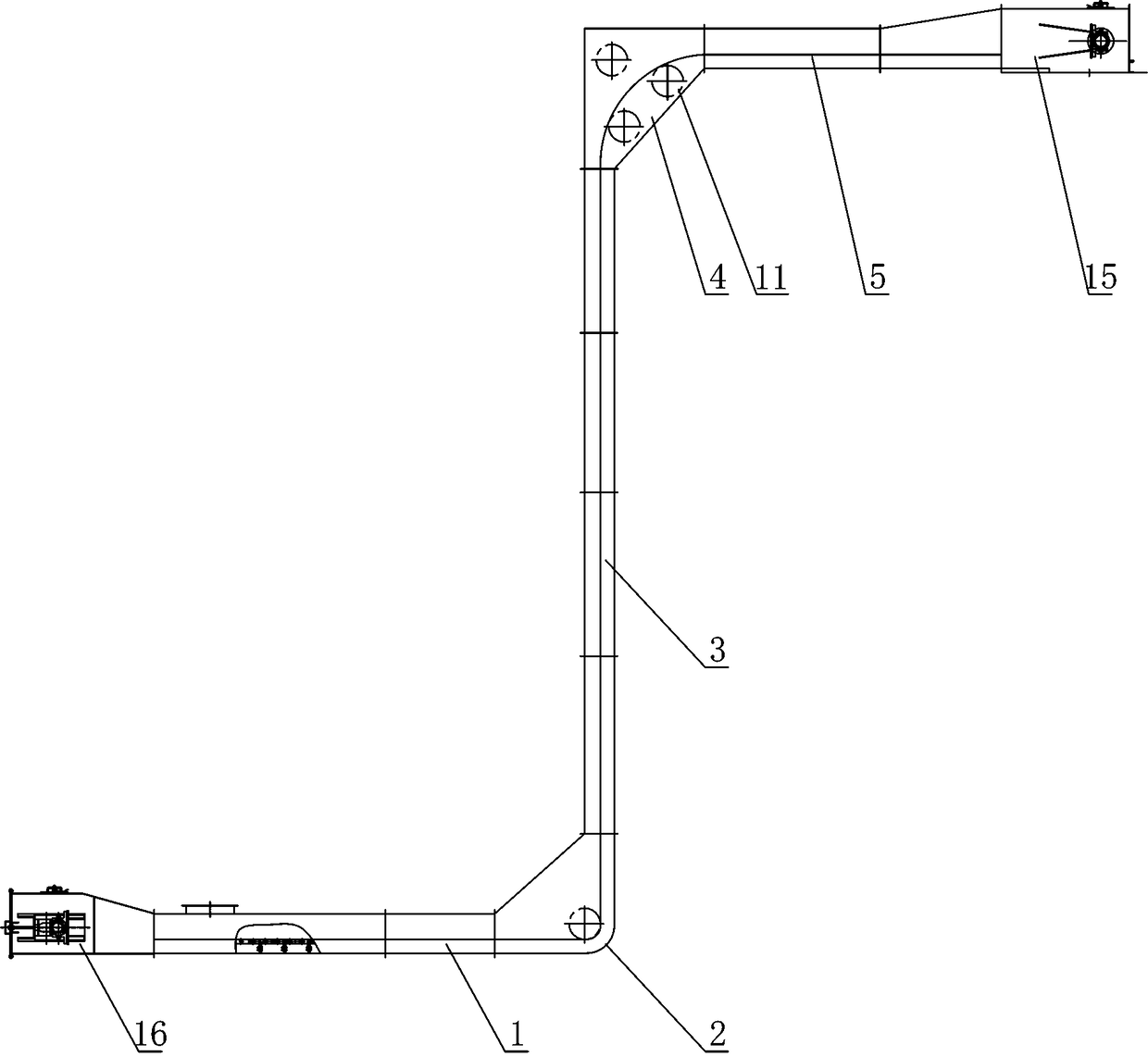

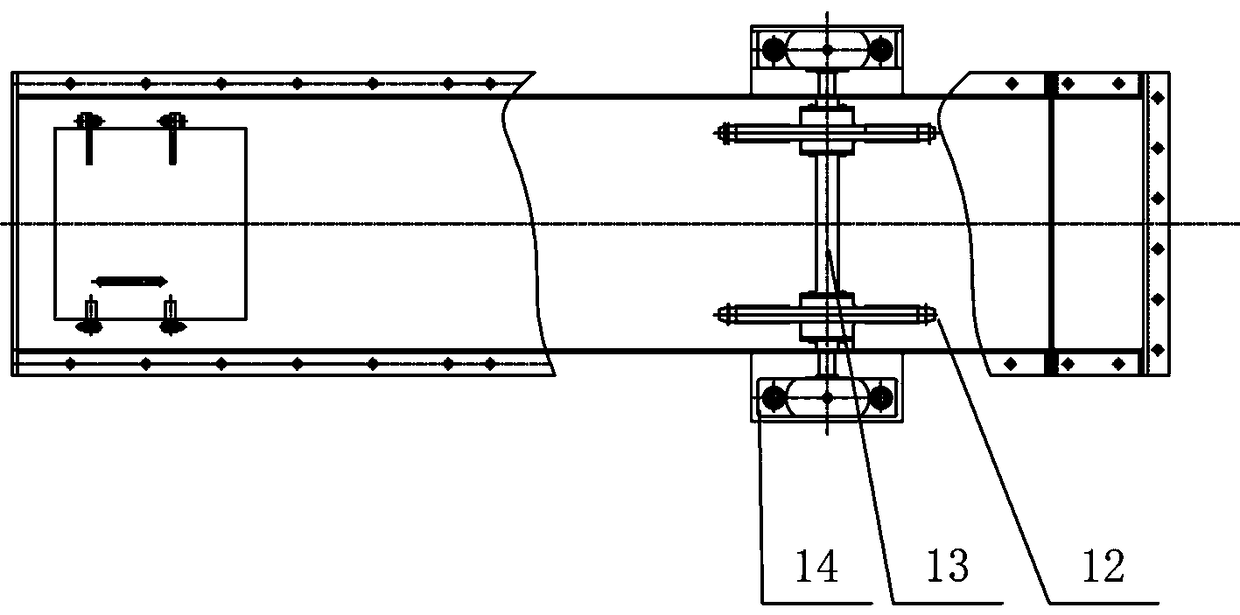

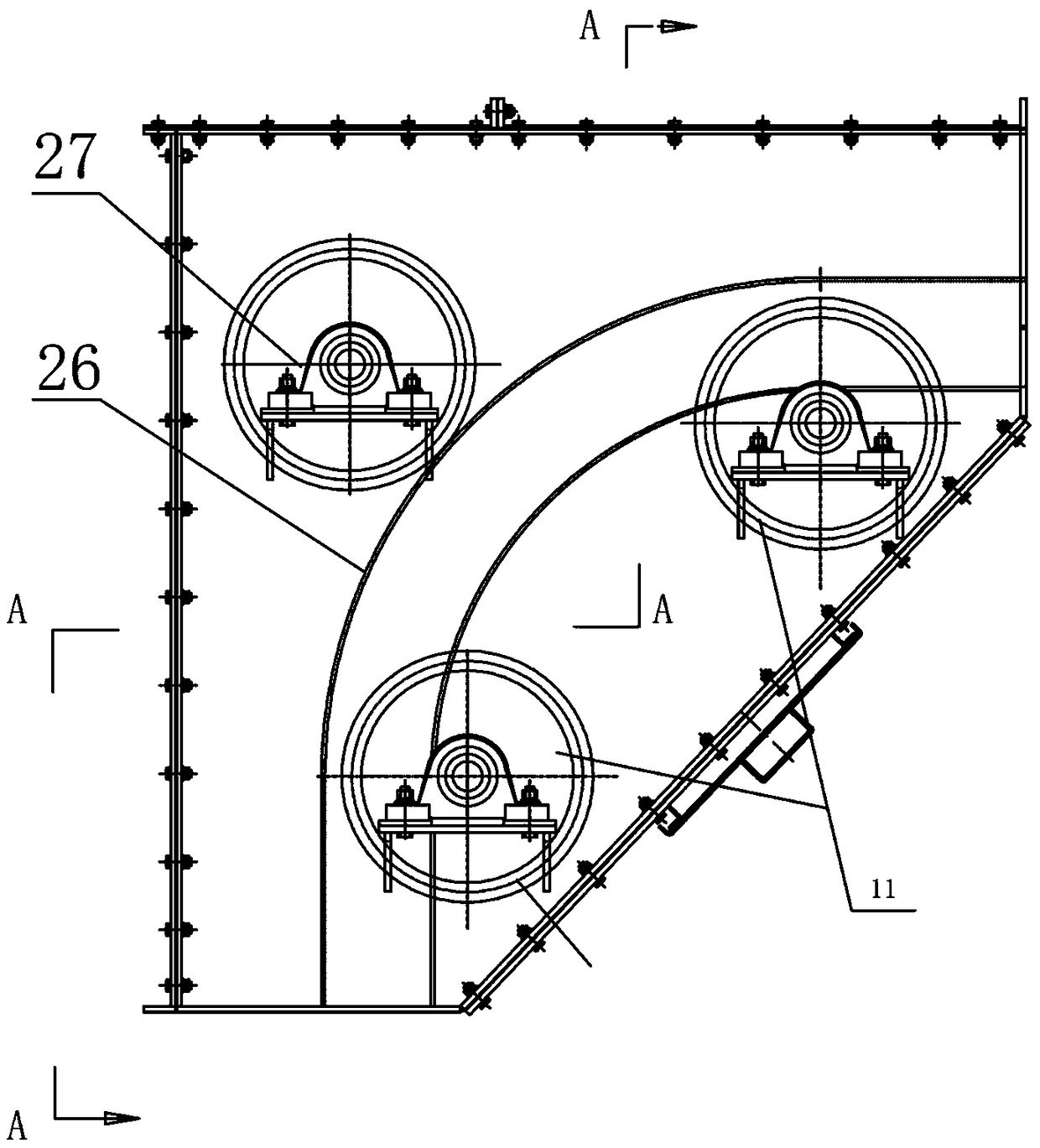

[0042] Such as Figure 1-2 As shown, a MZ type buried scraper sludge conveyor and its method include a tail 15, a lower horizontal section 1, a lower curved section 2, a vertical section 3, an upper curved section 4, an upper horizontal section 5 and a head 16. The casing 6 of the lower horizontal section 1, vertical section 3 and upper horizontal section 5 is a convex structure, the scraper chain is installed in the casing 6, and the double row roller chain 7 of the scraper chain is installed in the casing 6 On the waistcoat 8 of the scraper chain, the scraper 9 of the scraper chain is installed in the groove 10 of the housing 6 and keeps a distance from the groove 10 . Among them, the double-row roller chain and the scraper of the scraper chain are made of 304 stainless steel, and are treated with nitriding, which can prolong the service life of the scraper chain for highly corrosive sludge. Since semi-dry sludge is a relatively viscous material with a high sand content, th...

Embodiment 2

[0052] On the basis of embodiment 1, a kind of sludge conveying method that adopts above-mentioned MZ type buried scraper sludge conveyor comprises the following steps:

[0053] 1) Lower horizontal conveying: The scraper is placed outside the conveyor, and the scraper is placed on the inner side of the double chain, so that the scraper is on the outer side of the ring chain and the outer side of the head wheel. Due to the sludge that has just been semi-dried Uncooled, high temperature and moisture, very viscous, start the drive motor controlled by the speed controller, the sludge enters from the material port at the tail 16, and is transported by the driving force of the connecting plate in the groove , to transport the semi-dry sludge continuously and evenly to the lower bending section. When using ordinary single-chain MZ type buried scraper conveyor, the scraper is a V-shaped steel pipe and built with the chain, such as Figure 13 . The advancement of materials is based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com