Carbon nanotube modified thermoplastic elastomer composite material with solvent resistance and preparing method thereof

A thermoplastic elastomer, carbon nanotube modification technology, applied in the field of polymer materials, can solve the problems of low strength, easy aging, weak solvent resistance, etc., to achieve good solvent resistance, simple preparation method, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

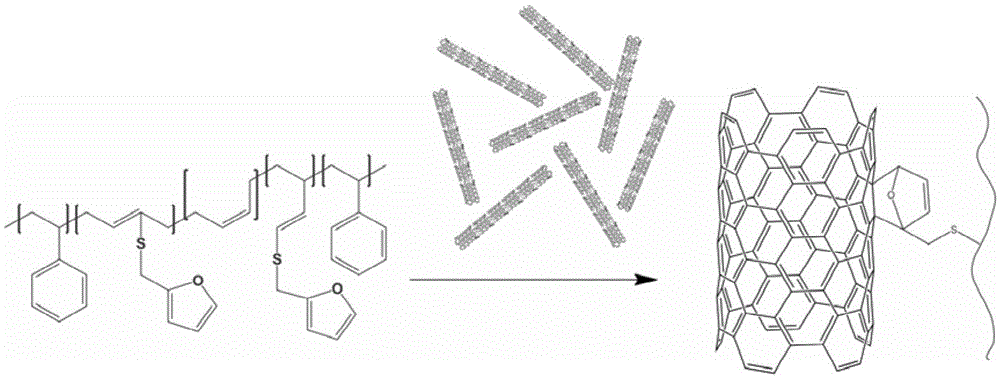

[0022] Dissolve and disperse the elastomer material modified by furan grafting (here the SBS with furan grafting amount of 20%) and carbon nanotubes (the contents are respectively 1%, 2.5%, 5%, 7.5% and 10%) In a solvent, heat and disperse evenly, and then form a film at 100°C. figure 1 is an equation for the reaction between furan-modified SBS (polystyrene-butadiene-styrene) and carbon nanotubes.

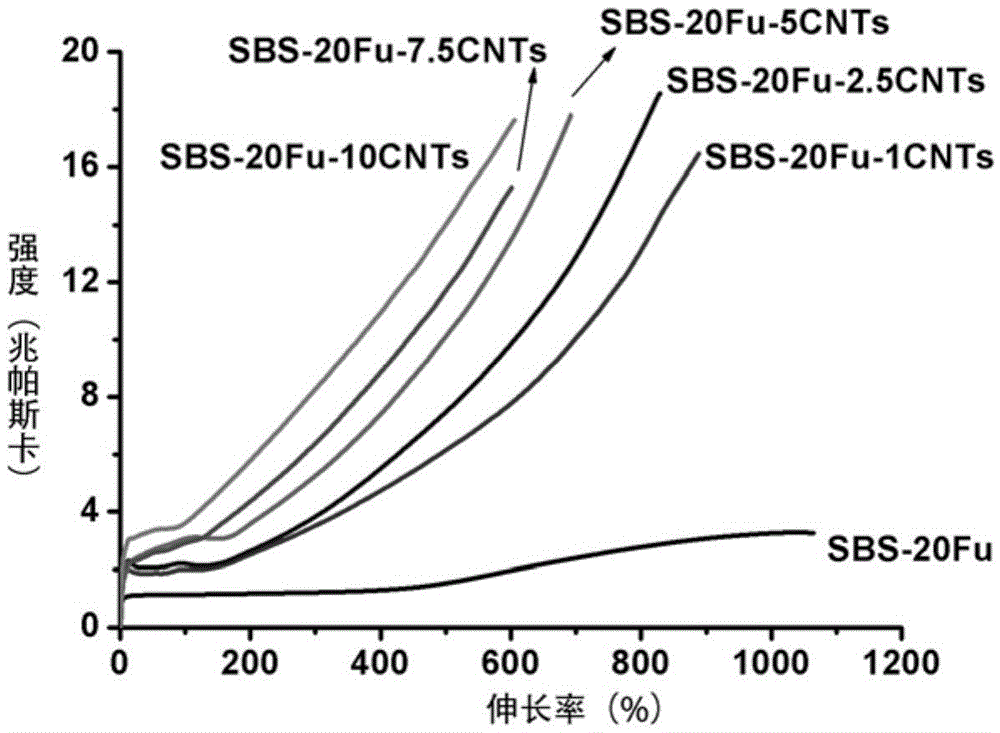

[0023] figure 2 It is the stress-strain curve figure of the composite material that the furan graft ratio is 20% and the composite material of different carbon nanotube additions in embodiment 1, and the carbon nanotube addition content is respectively 1%, 2.5%, 5%, 7.5% and 10%.

[0024] Table 1 is the SBS whose furan grafting ratio is 20% in the embodiment, and the carbon tube grafting amount is 1%, 2.5%, 5%, 7.5% and 10% the elongation at break and the modified SBS of reversible crosslinking Breaking strength.

[0025] Table 1

[0026] Addition amount of carbon tu...

Embodiment 2

[0028] Dissolve and disperse the elastomer material modified by furan grafting (30% SBS with furan grafting amount) and carbon nanotubes (1%, 2.5%, 5%, 7.5% and 10% respectively) In a solvent, heat and disperse evenly, and then form a film at 100°C.

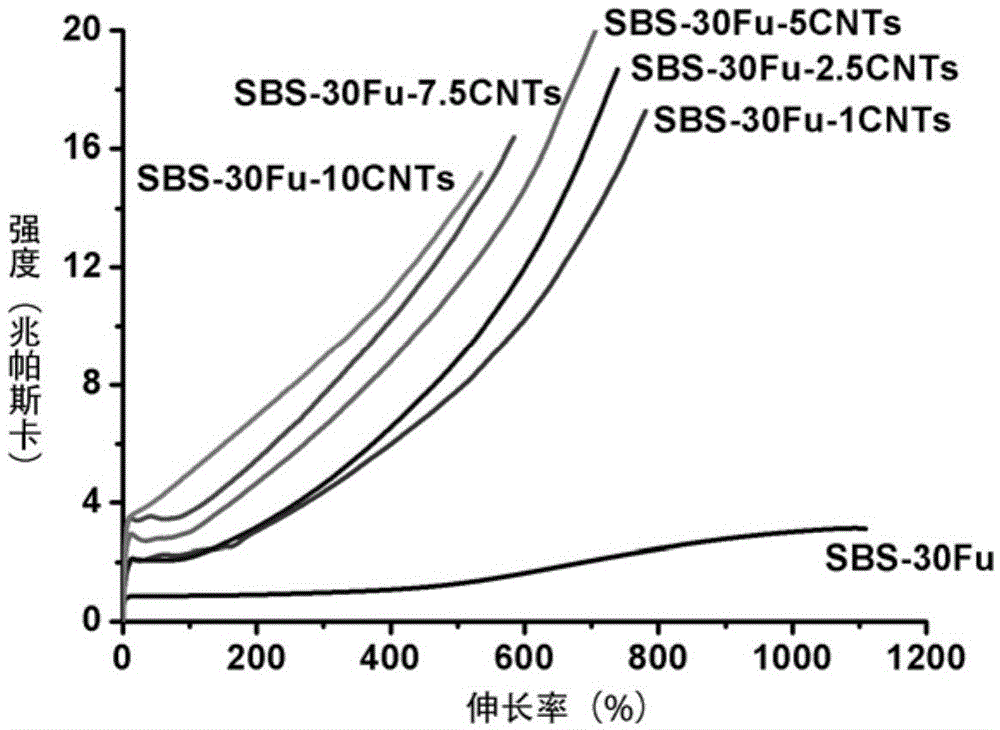

[0029] image 3 It is the stress-strain curve figure of the composite material that different furan graft ratios are 30% SBS (polystyrene-butadiene-styrene) and different carbon nanotube additions in embodiment 2, carbon nanotube addition content is respectively 1%, 2.5%, 5%, 7.5% and 10%.

[0030] Table 2 is the elongation at break of the reversibly cross-linked modified butadiene rubber of 30% SBS with furan grafting ratio in the examples, and 1%, 2.5%, 5%, 7.5% and 10% of carbon tube grafting rate and breaking strength.

[0031] Table 2

[0032] Addition amount of carbon tubes (%)

Embodiment 3

[0034] Soak the molded composite material in xylene and heat it to 150°C. At this time, the material dissolves. The solution is poured on a glass plate to form a film, which means that it is reshaped and reused. Taking a composite material with a furan grafting rate of 20% and a carbon nanotube addition of 10% as an example, the molding was repeated three times. The stress-strain curve is shown in Figure 4 . After the material is remolded each time, the breaking strength, elongation at break and modulus all decrease. The analysis is considered to be due to the fact that there is a small amount of residual carbon tubes and the crosslinking between the polymer does not Complete unraveling leads to a decrease in the degree of cross-linking of the reshaped material, so several parameters are decreased. But it still has good mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com