Tea seed essence with sweet osmanthus fragrance and preparation method of tea seed essence

A tea seed and aroma type technology is applied to the field of sweet-scented osmanthus-flavored tea seed essential oil and its preparation, which can solve the problems of damage to the antioxidant components of oil, low yield of tea seed essential oil, and high pressing temperature, and achieves a small degree of denaturation and is easy to use. The effect of large-scale production and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

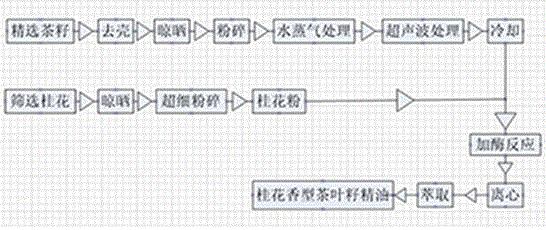

Image

Examples

Embodiment 1

[0026] (1) Broken shell: select tea seeds with good quality, no deterioration and mildew, and break the tea seeds so that the tea seed kernels are separated from the tea shells to obtain a mixture containing tea seed kernels and tea shells;

[0027] (2) Wind husk removal: Pour the mixed material into the windmill, and use the vertical gravity and horizontal wind to separate the tea seed kernel and tea husk;

[0028] (3) Drying treatment: drying the obtained tea seed kernels in the sun until the water content of the tea seed kernels is 5%, to obtain dry tea seed kernels;

[0029] (4) Steam: Pour the dry tea seed kernels into a superfine pulverizer, pulverize them to 70 mesh and sieve them, then perform 10min steam pretreatment at 0.15MPa;

[0030] (5) Ultrasonic treatment: ultrasonicate the pretreated mixture again at a temperature of 50°C at a frequency of 30kHz for 10 minutes, and cool it down to obtain a tea mixture;

[0031] (6) Superfine crushing: select good quality and ...

Embodiment 2

[0035] (1) Broken shell: select tea seeds with good quality, no deterioration and mildew, and break the tea seeds so that the tea seed kernels are separated from the tea shells to obtain a mixture containing tea seed kernels and tea shells;

[0036] (2) Wind husk removal: Pour the mixed material into the windmill, and use the vertical gravity and horizontal wind to separate the tea seed kernel and tea husk;

[0037] (3) Drying treatment: drying the obtained tea seed kernels in the sun until the water content of the tea seed kernels is 6%, to obtain dry tea seed kernels;

[0038] (4) Crushing and steaming: Pour the dried tea seeds into a superfine pulverizer, superfine pulverize to 80 mesh and sieve, then perform 20min steam pretreatment at 0.18MPa;

[0039] (5) Ultrasonic treatment: Ultrasonicate the pretreated mixture for 20 minutes at a frequency of 45 kHz at a temperature of 60° C., and cool it to obtain a tea mixture;

[0040] (6) Grinding: select good-quality and non-rot...

Embodiment 3

[0044] (1) Broken shell: select tea seeds with good quality, no deterioration and mildew, and break the tea seeds so that the tea seed kernels are separated from the tea shells to obtain a mixture containing tea seed kernels and tea shells;

[0045] (2) Wind husk removal: Pour the mixed material into the windmill, and use the vertical gravity and horizontal wind to separate the tea seed kernel and tea husk;

[0046] (3) Drying treatment: drying the obtained tea seed kernels in the sun until the water content of the tea seed kernels is 7%, to obtain dry tea seed kernels;

[0047] (4) Crushing and steaming: Pour the dried tea seeds into an ultra-fine pulverizer, ultra-fine pulverize to 90 mesh and sieve, then perform steam pretreatment at 0.20 MPa for 30 minutes;

[0048] (5) Ultrasonic treatment: ultrasonicate the pretreated mixture for 30 minutes at a frequency of 60 kHz at a temperature of 70° C., and then cool it to obtain a tea mixture;

[0049] (6) Ultra-fine crushing: sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com