Preparation method of terrace-shaped appearance Al-Cu-Fe quasi crystal block material

A technology of al-cu-fe and bulk materials, which is applied in the field of preparation of quasi-crystal materials, can solve the problems of difficult to observe regular geometric growth morphology, provide favorable information, complex process, etc. Sensitive, process stable, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

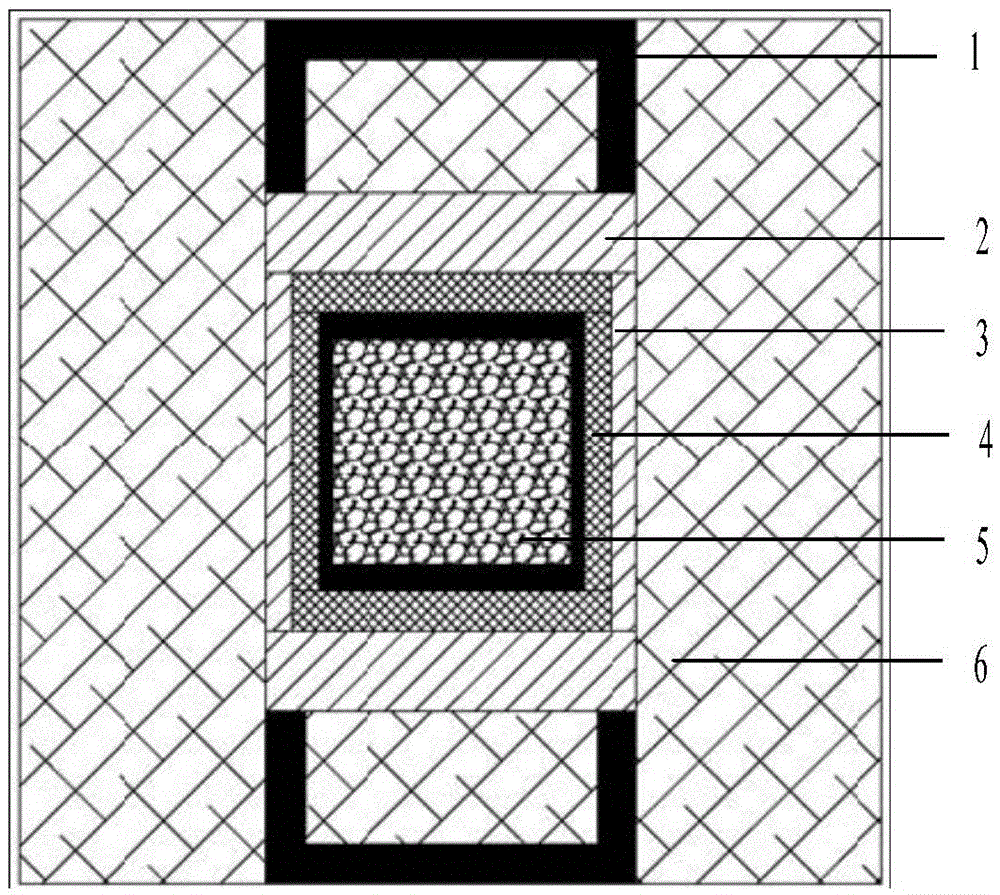

[0023] In an inert gas (Ar gas) environment glove box (H 2 O2 99.9% (according to Al 57 Cu 40 Fe 3 Weigh), put it into an agate mortar and mix well, put the mixed powder into a hard alloy abrasive tool with an inner diameter of Φ9.5mm, pressurize to 3MPa on a hydraulic tablet press, hold the pressure for 2 minutes, and obtain the thickness 10mm preform.

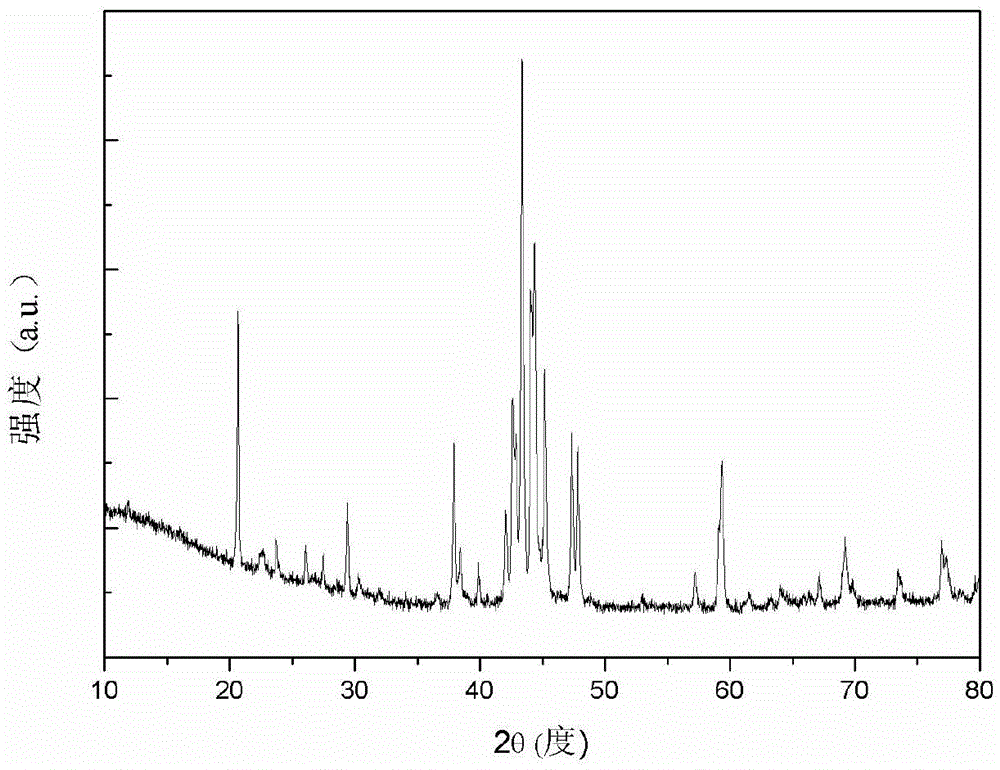

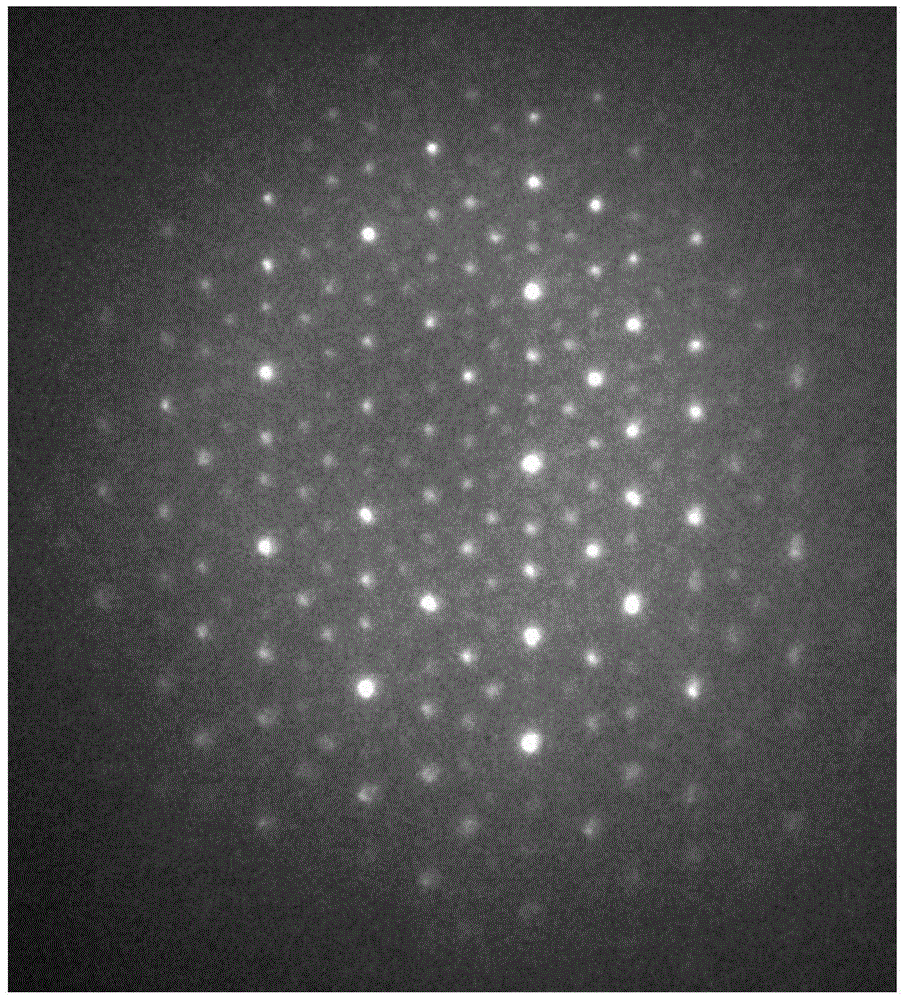

[0024] Put the preform into the crucible combined with h-BN crucible and graphite heating element, place it in a drying box at 180°C to remove the adsorbed water vapor, and then carry out high-pressure preparation in a hinged six-sided top press. First, raise the pressure to 3GPa, control the heating rate to 50K / min, heat to 1373K, keep the temperature and hold the pressure for 30 minutes. Subsequently, the cooling rate is controlled to be 100K / min, the temperature is lowered to 1073K, and the heat preservation and pressure are maintained for 2 hours, and the Al with terraced field shape is obtained. 57 Cu 40 Fe 3 bulk...

Embodiment 2

[0027] In a vacuum environment glove box, 1.0324g of Al powder, 1.8126g of Cu powder, and 0.1554g of Fe powder with a purity>99.9% were weighed according to the atomic weight ratio (according to Al 55 Cu 41 Fe 4 Weigh), put it into an agate mortar and mix well, put the mixed powder into a hard alloy abrasive tool with an inner diameter of Φ9.5mm, pressurize to 2MPa on a hydraulic tablet press, hold the pressure for 5 minutes, and obtain the thickness 10mm preform.

[0028] Put the preform into the crucible combined with h-BN crucible and graphite heating element, place it in a drying box at 180°C to remove the adsorbed water vapor, and then carry out high-pressure preparation in a hinged six-sided top press. First, raise the pressure to 6GPa, control the heating rate to 40K / min, heat to 1273K, and hold the temperature and pressure for 60 minutes. Subsequently, the cooling rate is controlled to be 100K / min, the temperature is lowered to 973K, and the heat preservation and pr...

Embodiment 3

[0031] In an inert gas (N 2 gas) environmental glove box (H 2 O2 99.9% according to the atomic weight ratio (according to Al 52 Cu 42 Fe 6 Weigh), put it into an agate mortar and mix well, put the mixed powder into a hard alloy abrasive tool with an inner diameter of Φ9.5mm, pressurize to 4MPa on a hydraulic tablet press, hold the pressure for 3 minutes, and obtain the thickness 10mm preform.

[0032] Put the preform into the crucible combined with h-BN crucible and graphite heating element, place it in a drying oven with a temperature of 180°C to remove the adsorbed water vapor, and then carry out high-pressure preparation in a hinged six-sided top press. First, raise the pressure to 4GPa, control the heating rate to 60K / min, heat to 1300K, keep the temperature and hold the pressure for 40 minutes. Subsequently, the cooling rate was controlled to be 100K / min, the temperature was lowered to 1000K, and the heat preservation and pressure were held for 2.5 hours to obtain Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com