A non-electrical signal acquisition and monitoring method

A signal acquisition, non-electrical technology, applied in the field of data measurement, can solve the problems of wrong judgment results, large time changes, and difficulty in detecting non-electrical signals, so as to avoid losses, reduce risks, and avoid serious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

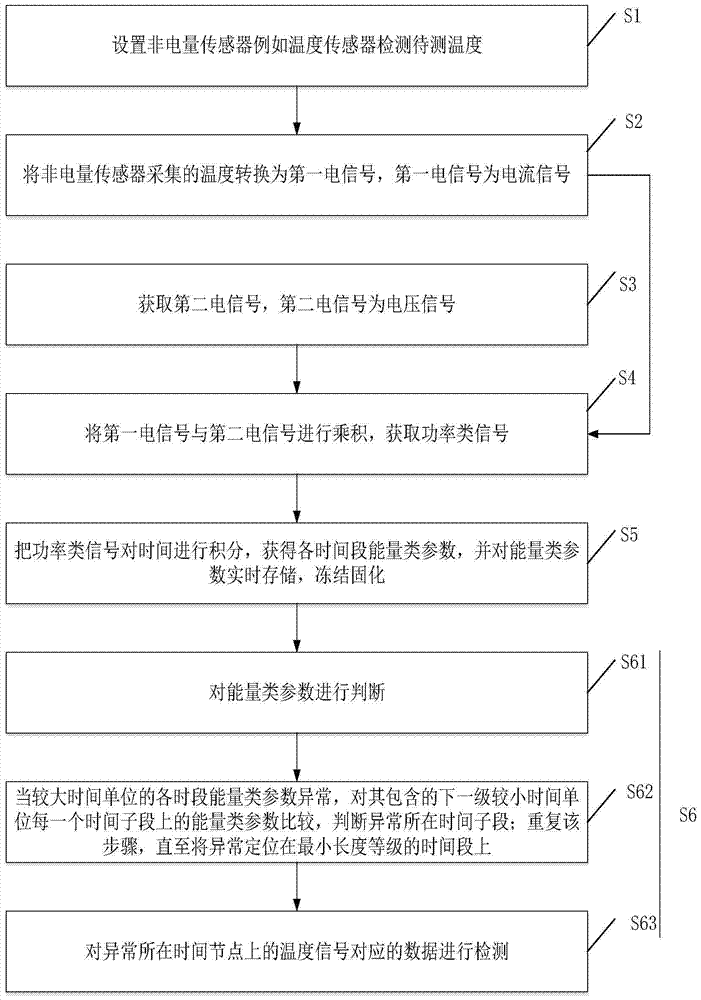

[0031] refer to figure 1 , a non-electrical signal acquisition and monitoring method proposed in this embodiment is used to detect temperature, which includes the following steps:

[0032] S1. Set a non-electrical sensor such as a temperature sensor to detect the temperature to be measured.

[0033] S2. Convert the temperature collected by the non-electrical quantity sensor into a first electrical signal, where the first electrical signal is a current signal.

[0034] Specifically, in this embodiment, the variable resistance temperature sensor can be selected as the non-electricity sensor, such as a thermistor. In this way, the temperature collected by the non-electricity sensor can be converted into current signal.

[0035] S3. Acquire a second electrical signal, where the second electrical signal is a voltage signal. In this step, the second electrical signal is a value preset by the software, specifically, 1V or its multiple can be selected. During specific implementati...

Embodiment 2

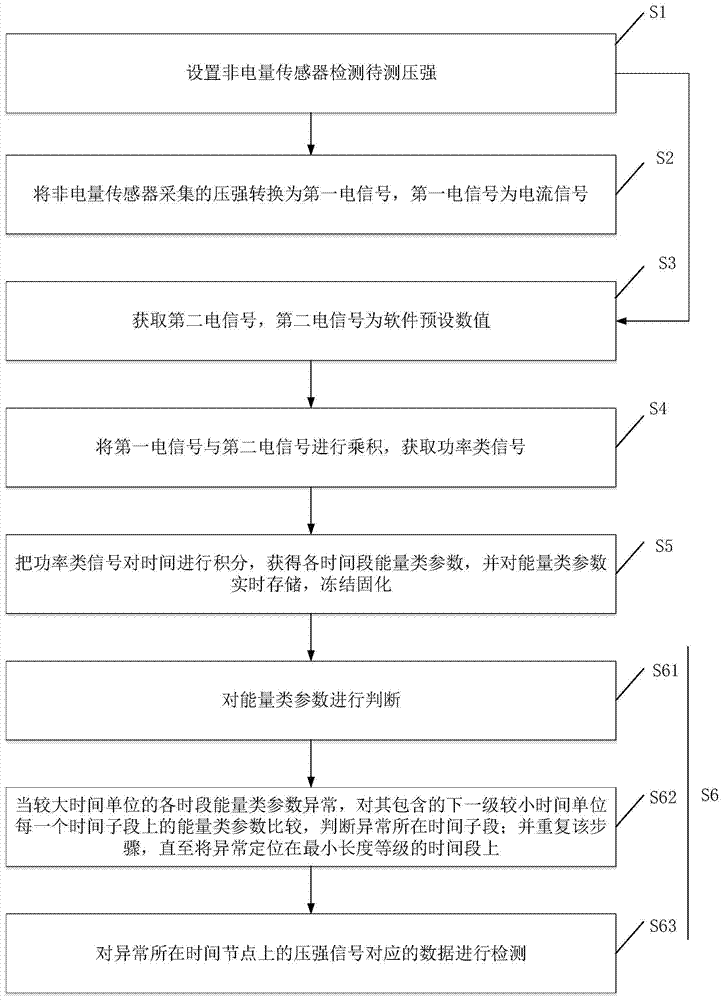

[0048] refer to figure 2 , a non-electrical signal acquisition and monitoring method proposed in this embodiment is used to detect pressure, which includes the following steps:

[0049] S1. A non-electrical sensor is set to detect the pressure to be measured.

[0050] S2. Convert the pressure collected by the non-electrical quantity sensor into a first electrical signal, where the first electrical signal is a current signal.

[0051] Specifically, in this embodiment, the variable-value resistance non-electricity sensor can be selected as the non-electricity sensor, such as a pressure sensing resistor. converted to a current signal.

[0052] S3. Acquire a second electrical signal, where the second electrical signal is a voltage signal. In this step, the second electrical signal is a value preset by the software, specifically, 1V or its multiple can be selected. During specific implementation, an auxiliary circuit may also be provided to obtain the second electrical signal fr...

Embodiment 3

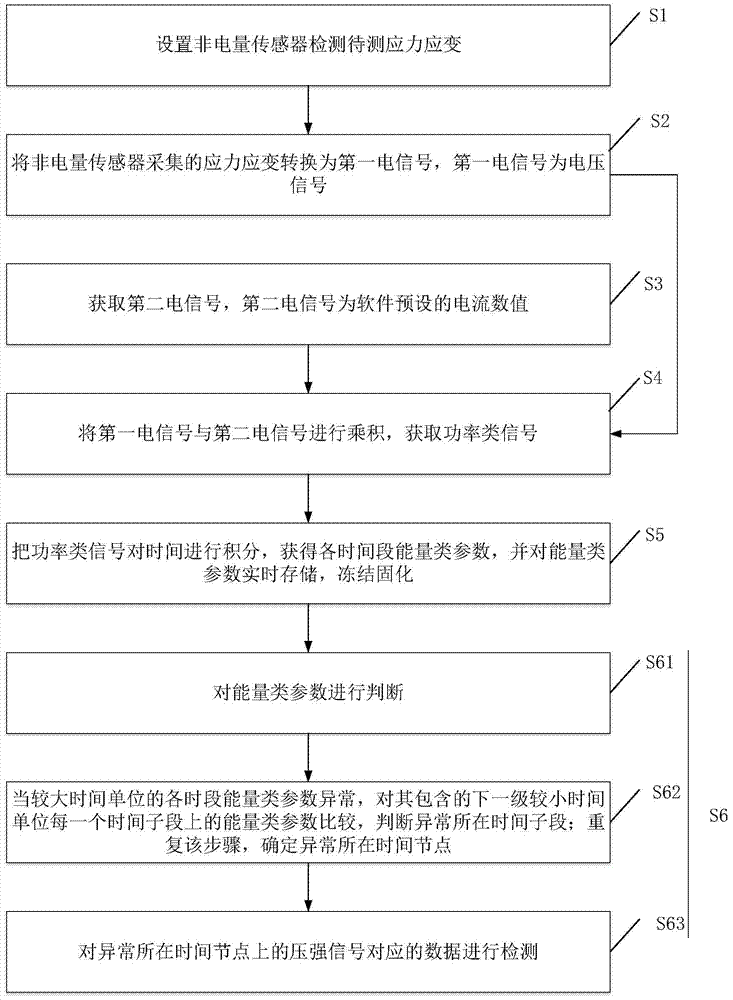

[0064] refer to image 3 , a non-electrical signal acquisition and monitoring method proposed in this embodiment is used to detect stress signals, which includes the following steps:

[0065] S1. A non-electrical sensor is set to detect the stress to be measured.

[0066] S2. Indirectly convert the stress collected by the non-electrical quantity sensor into a first electrical signal, where the first electrical signal is a voltage signal.

[0067] Specifically, in this embodiment, a non-electrical sensor whose output is not a voltage or current signal is specially selected, such as a resonant non-electrical sensor. In this way, through a software method, first, the frequency value corresponding to the stress value is converted into a value corresponding to the stress value. , and then indirectly convert the stress value into a proportional voltage value. For example, by using direct unit conversion, the stress unit Newton (N) is converted into the voltage unit volt (V), and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com