Distributed fiber sensing technical scheme and system for monitoring of concrete panel dam seepage

A technology of distributed optical fiber and sensing technology, applied in the field of distributed optical fiber sensing technology type and system, can solve the problems of not being reasonably reliable, the optical demodulator is not fully applicable, and the electric heat energy is small, and achieves on-site laying protection. Large workload, guaranteed on-site protection and survival rate, and sufficient heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

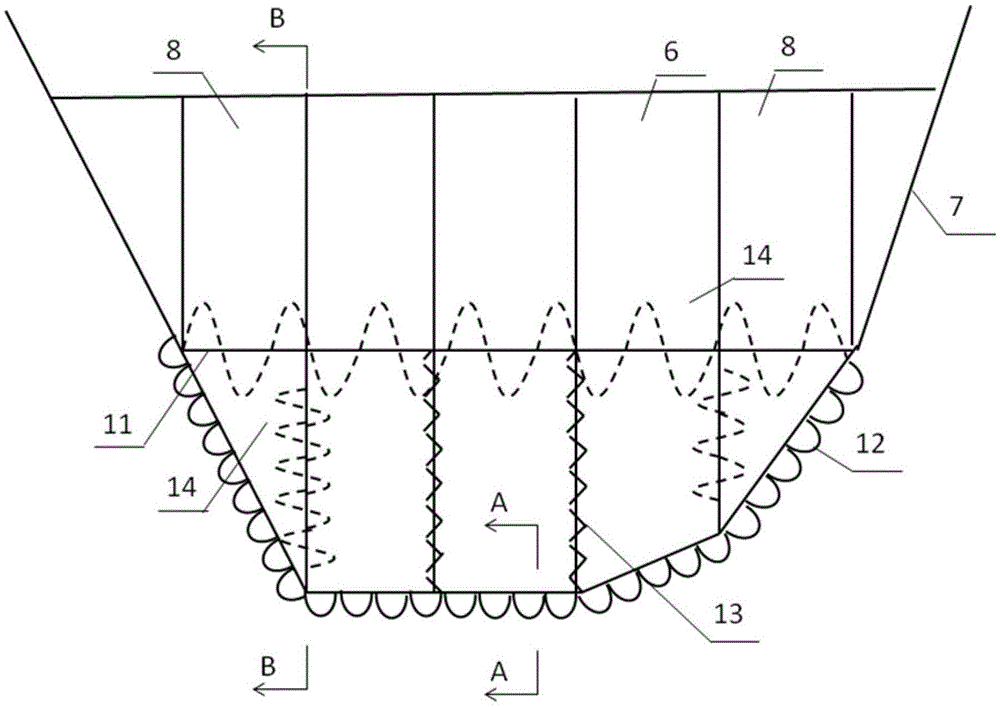

[0042] (1) In the asphalt (cement) mortar cushion layer laid under the peripheral seam-vertical seam of the panel, a groove for laying photoelectric composite cables is reserved along the lower opening of the seam surface, about 15~25cm wide and 8~15cm deep, and optical cables are laid at the bottom of the groove (The distance between the two optical cables is about 1~3cm). After the optical cable is laid, installed and positioned and inspected by OTDR, the laying groove is filled with gravel material and manually compacted and leveled. Construction details: The PVC gasket laid on the top surface of the mortar cushion can extend to the bottom surface of the embedding groove, but do not cover the optical cable or fill the gravel material; when the laying groove is adjacent to the subsequent concrete pouring operation, do not let the concrete material or cement slurry into the laying groove, to avoid covering / pollution of optical cables and gravel filling materials.

[0043] Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com