Method for detecting anions in active ink

A technology of reactive ink and detection method, which is applied in measurement devices, material separation, instruments, etc., can solve the problems of tailing, poor detection accuracy, and high detection cost, and achieve the effect of solving detection problems, reducing enterprise costs and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

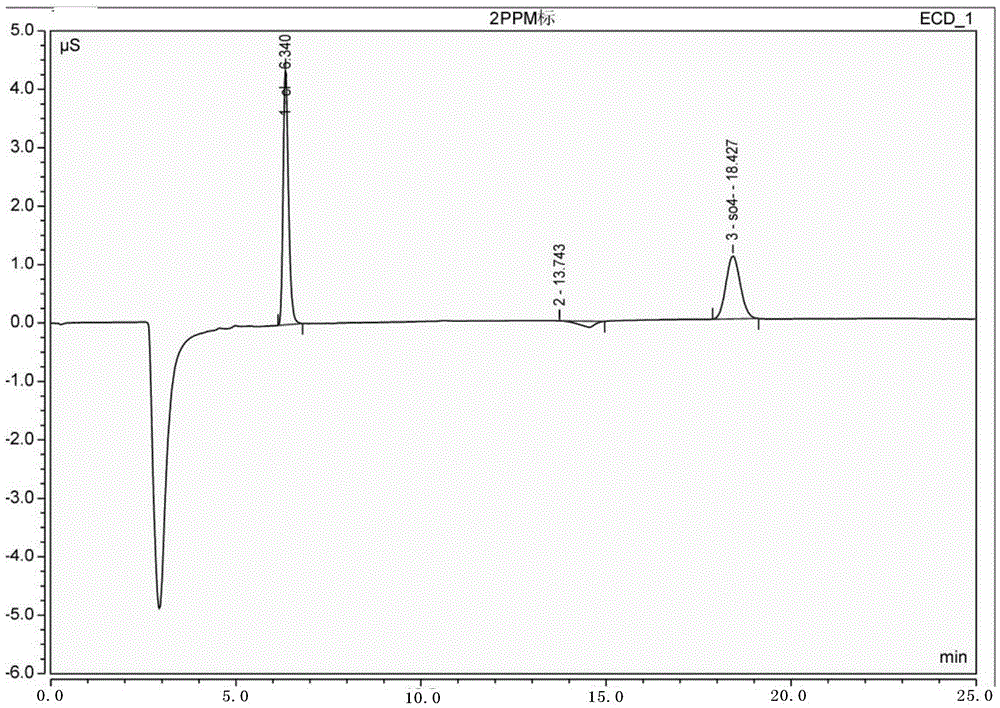

[0044] (1) Introduce the standard sample into the Dianne ics-900 ion chromatograph with a new enrichment column, collect the signal data, and the obtained result is the same as figure 1 similar;

[0045] (2) According to the method of "Dian ics-900 ion chromatograph operating procedures", the Dion ics-900 ion chromatograph is used to continuously detect the sample to be tested. After each test is completed, adjust the valve and use the flushing liquid ( 70% acetonitrile aqueous solution) to rinse the pretreatment column for 30 minutes, balance the instrument with mobile phase (deionized water) before each detection until the baseline is stable, after continuous detection of 200 samples, the detection effect is still good;

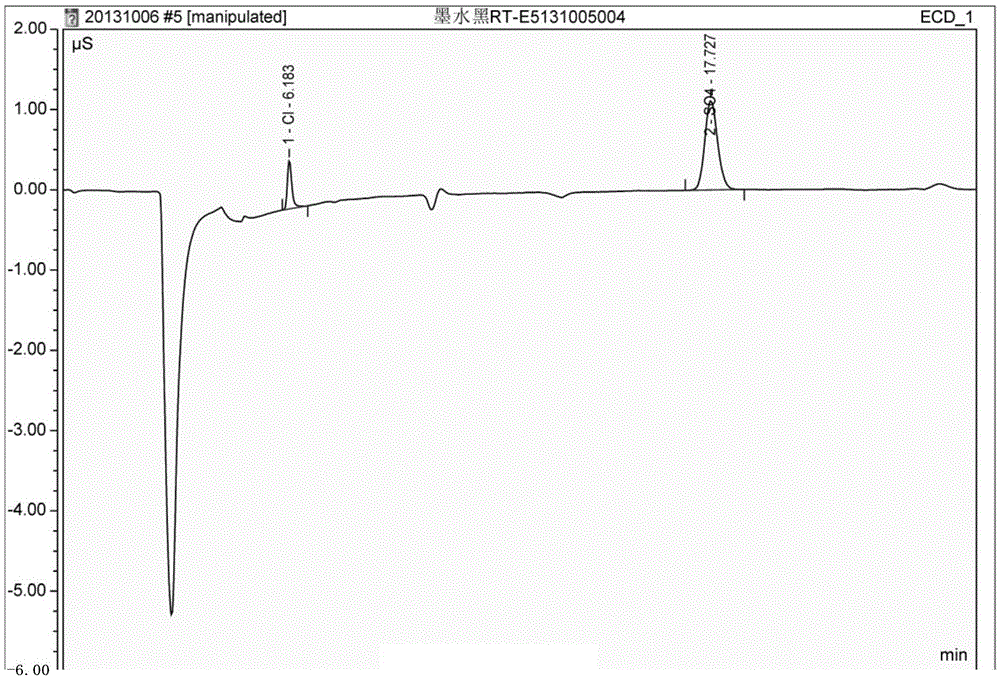

[0046] (3) Enter the standard sample into the Diane ics-900 ion chromatograph after detecting 200 samples, collect signal data, and the obtained results are as follows image 3 shown.

[0047] From image 3 It can be seen that after adopting the method o...

Embodiment 2~5

[0049] The operation mode of Examples 2 to 5 is exactly the same as that of Example, the difference is that the flushing solution in step (2) is changed, and when the enrichment effect of the record enrichment column is obviously decreased, the number of samples detected and the used The number of samples tested when the flushing solution and the effect decrease

[0050] The detection condition and detection result of table 1 embodiment 2~5

[0051]

Embodiment 6~9

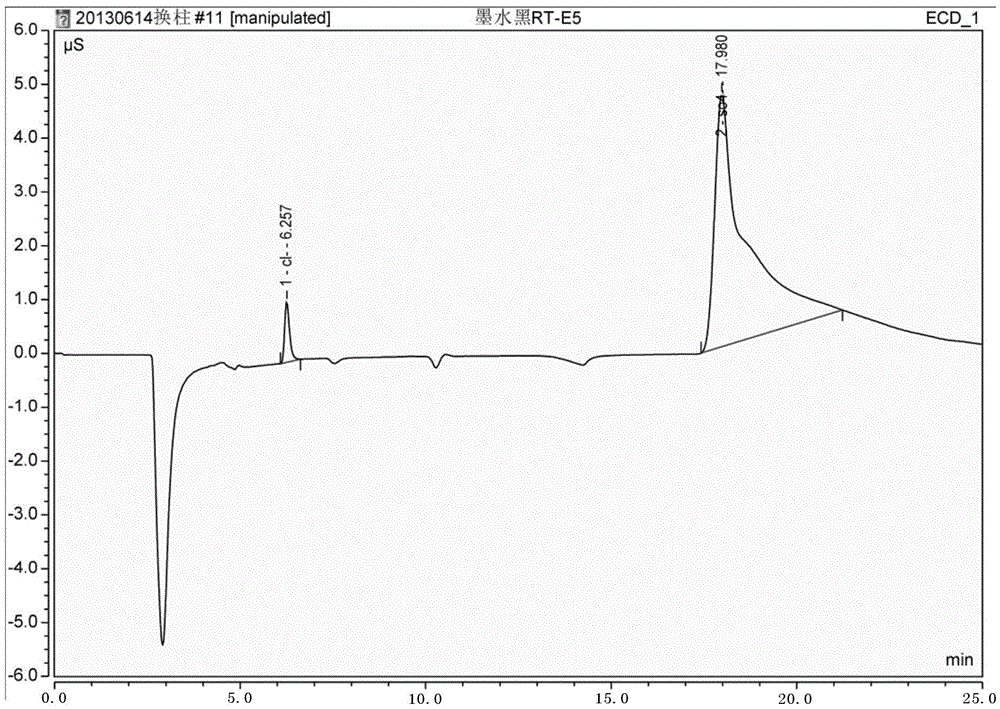

[0053] Turn on the ion chromatograph, equilibrate the instrument for 1 hour, and start sample injection after the instrument is well balanced. The sample is brought into the pretreatment column (the pretreatment column is a C18 column) by the mobile phase, and organic matter such as dyes is retained on the pretreatment column. The switching anions of the valve are directly brought into the enrichment column by the mobile phase, and then brought into the guard column through the mobile phase of the six-way valve in the enrichment column, and then directly enter the ion separation column for separation and detection after passing through the guard column. The organic matter remaining on the pretreatment column is washed by the flushing liquid and directly enters the waste liquid bottle after the valve is switched. The detection conditions of Examples 6 to 9 are shown in Table 2, and the chromatogram obtained in Example 6 is shown in Table 2. Figure 4 , the chromatogram that embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com