Device for generating diffraction-free needle-shaped light field

A non-diffraction, needle-type technology, applied in the field of modern photonics, can solve the problem of insufficient conversion efficiency, and achieve the effect of low cost, simple optical path and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

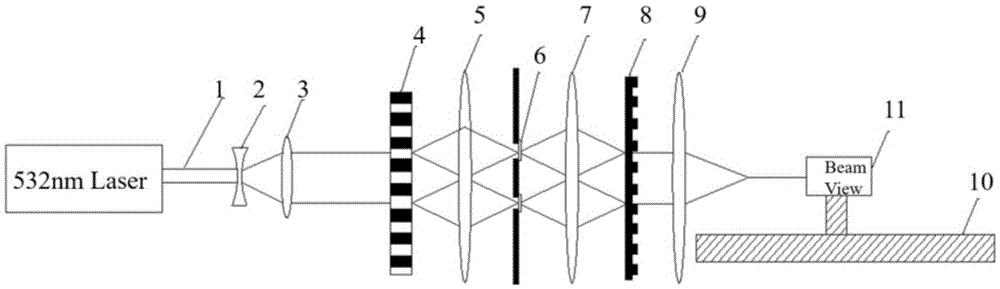

[0018] Such as figure 1 Shown is a device for generating a non-diffraction needle-shaped light field, including a beam expander collimation system, a radial polarization change vector beam generation system, and a needle-shaped light field detection system; the beam expander collimator system includes a concave lens 2 and a second A convex lens 3, the radial polarization change vector beam generating system includes a spatial light modulator 4, a second convex lens 5, a 1 / 4 wave plate 6, a third convex lens 7 and a Ronchi grating 8, and the needle-shaped light field detection system Including a fourth convex lens 9, an electric displacement platform 10 and a beam analyzer 11, the second convex lens 5 and the third convex lens 7 form a 4F system, and the beam analyzer 11 is fixed on the electric displacement platform 10;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com