Modeling Method for Thermal Drift of CNC Machine Tool Spindle Based on fa‑lssvm

A technology of CNC machine tools and modeling methods, which is applied in simulators, program control, computer control, etc., can solve the problems of significant impact on prediction accuracy, unsatisfactory model prediction accuracy and robustness, etc. Thermal error, the effect of a large search range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

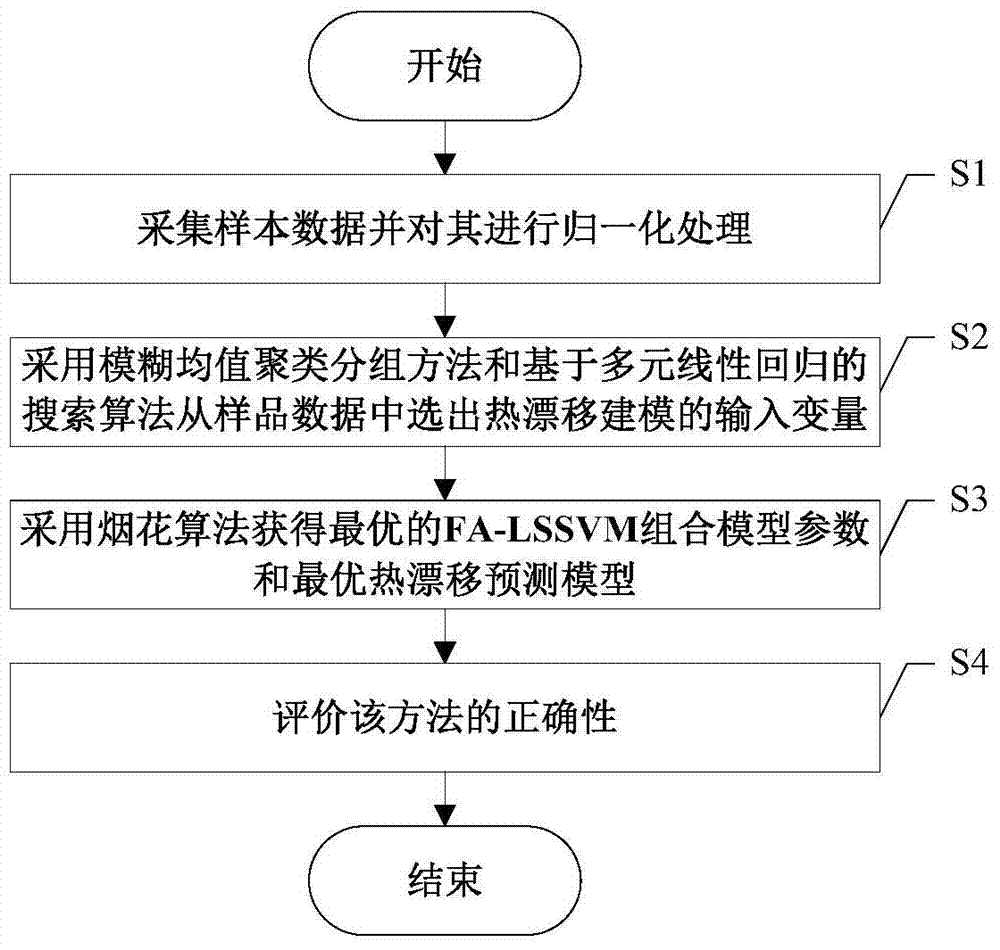

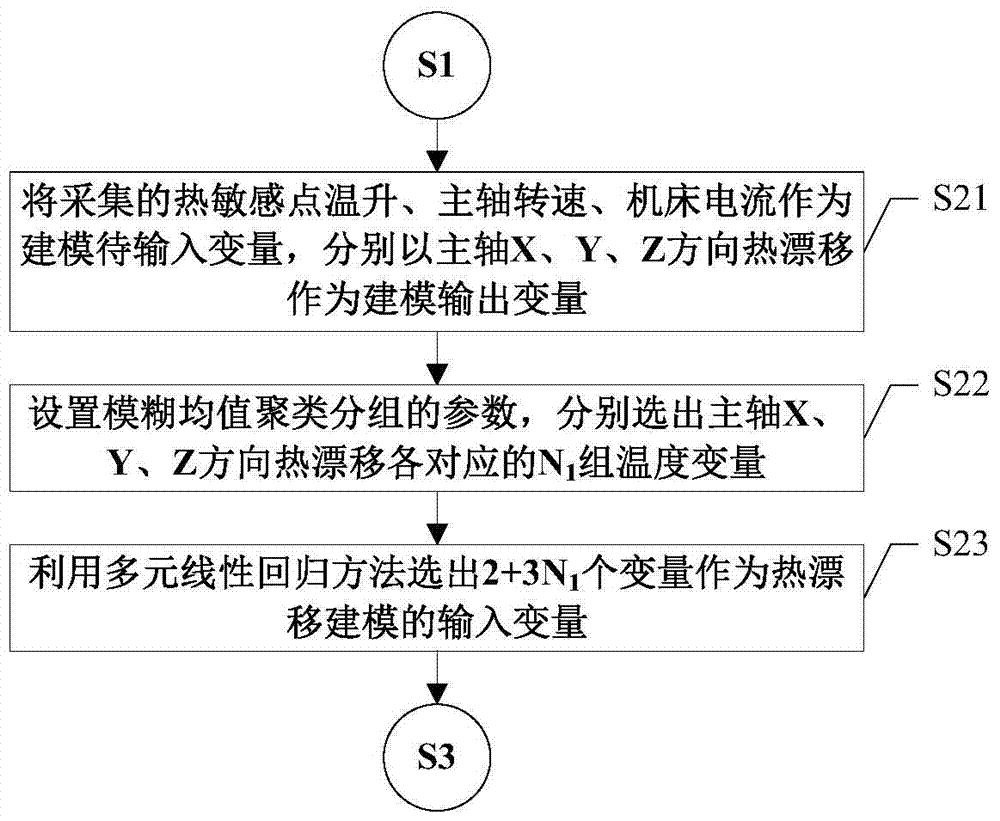

[0036] The present invention provides a FA-LSSVM-based thermal drift modeling method for CNC machine tool spindles, such as figure 1 shown, including the following steps:

[0037] S1. Collect sample data and perform normalization processing on it.

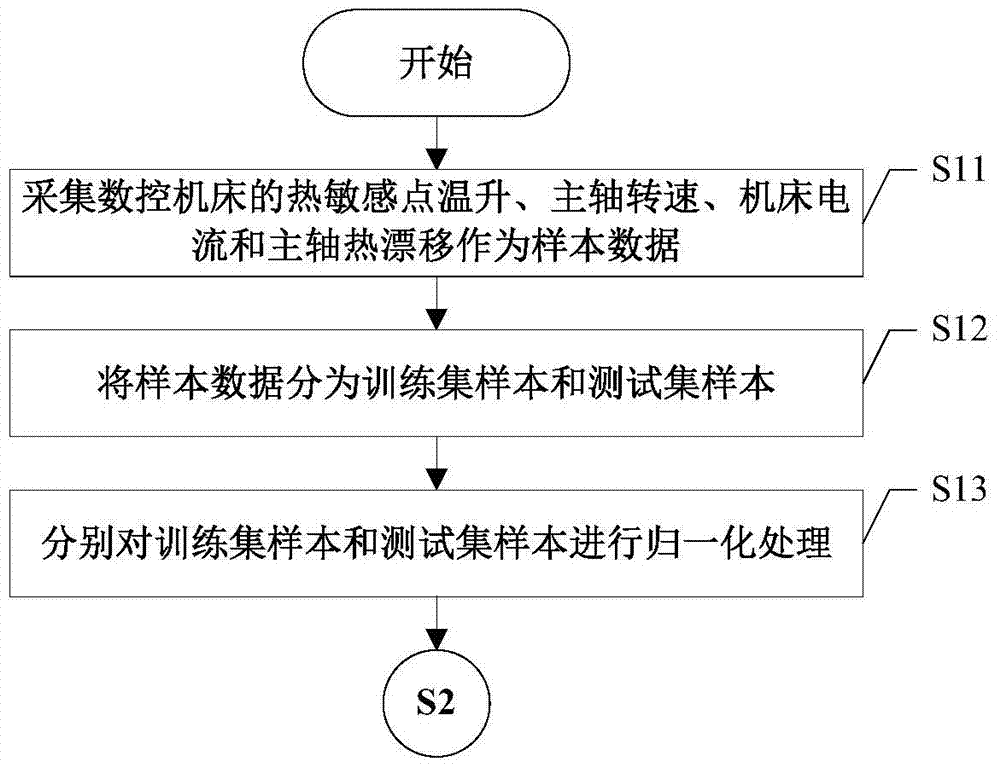

[0038] like figure 2 As shown, this step includes the following sub-steps:

[0039] S11. Collect the temperature rise of thermally sensitive points, spindle speed, machine current and spindle thermal drift of the CNC machine tool as sample data, wherein the temperature rise of thermally sensitive points, spindle speed, and machine tool current are used as input variables for modeling the thermal drift of the machine tool spindle , the spindle thermal drift is used as the output variable of the machine tool spindle thermal drift modeling.

[0040] S12. Divide the sample data into training set samples and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com