Optical fingerprint sensor, and manufacturing method and fingerprint acquisition method thereof

A technology of a fingerprint sensor and a manufacturing method, which are applied in the directions of acquiring/arranging fingerprints/palmprints, printing image collection, instruments, etc., can solve the problems that the structure of the optical fingerprint sensor needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

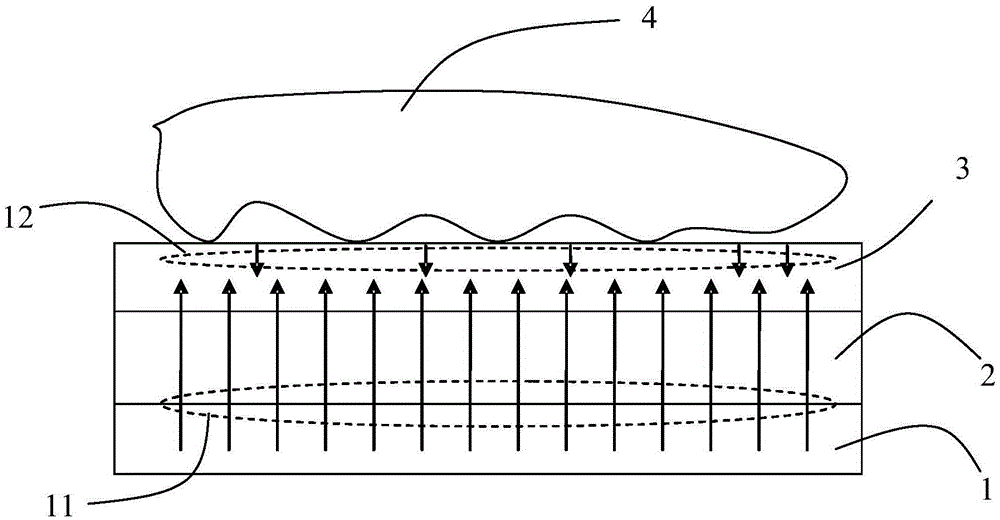

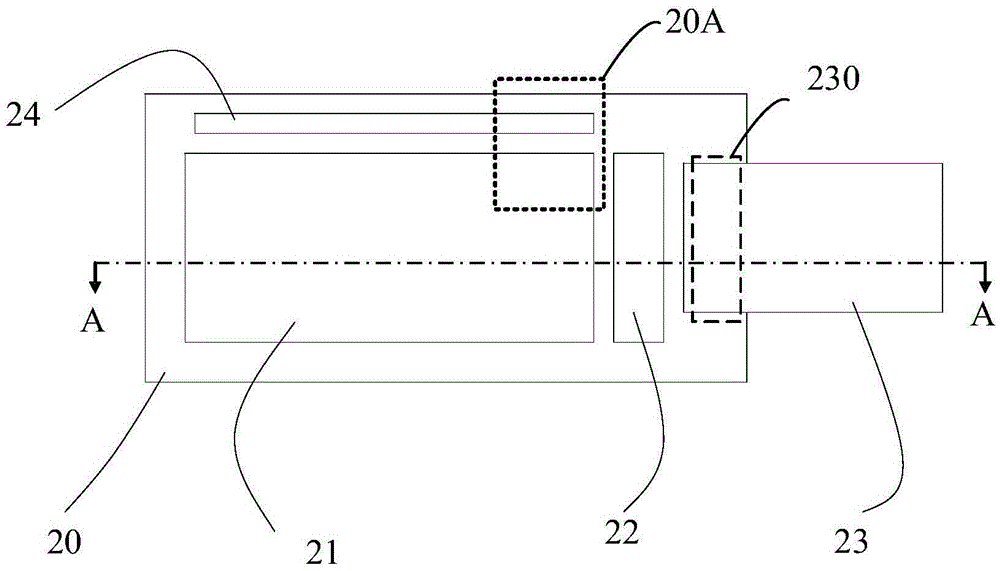

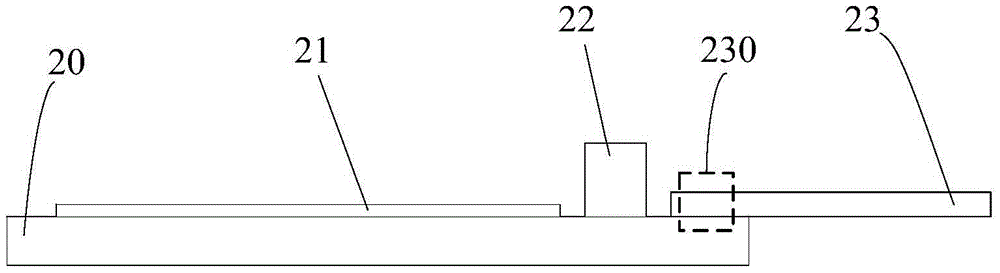

[0058] Since the optical fingerprint sensor requires a relatively high resolution, generally as high as 500dpi (dots per inch, dots per inch), the distance between the data lines in the optical fingerprint sensor is relatively small. In existing optical fingerprint sensors, the distance between adjacent data lines is only about 50 μm or even smaller. Such a small distance can easily cause poor bonding between the chip and the printed circuit board.

[0059] In an existing optical fingerprint sensor, a flexible printed circuit board (Flexible Printed Circuit, FPC) is bound by a film on glass process (Film On Glass, FOG). When the distance between the data lines is only about 50 μm or even smaller, in the process of flexible printed circuit board bonding, the problem of binding alignment deviation is very likely to occur. The alignment deviation of FOG is very large, resulting in flexible printed circuit board binding. The probability of failure is further increased. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com