Coal-fired flue gas purification device

A purification device and coal-fired flue gas technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of acid mist and aerosol and other pollutants that cannot be stably operated for a long time and deep removal, and achieve effective The effect of trapping and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

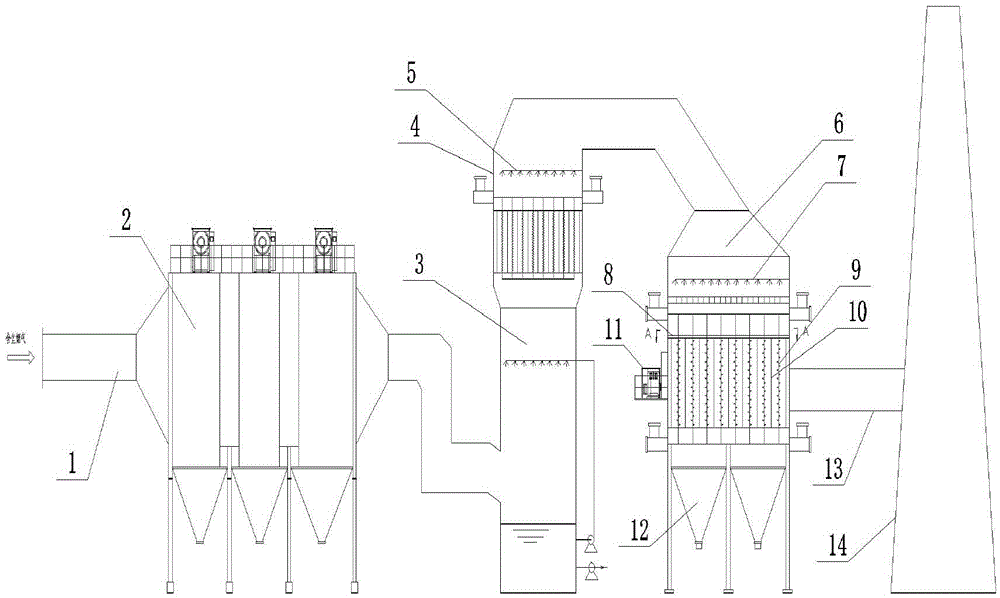

[0046] Below in conjunction with accompanying drawing, the present invention is further described;

[0047] In this example: the coal-fired unit is the flue gas produced by 300MW thermal power generation, the temperature of the flue gas after denitrification is 150°C, and the concentration of particulate matter in the flue gas after denitrification is 5g / Nm 3 ; In this embodiment, the flue gas treatment capacity of the equipment per unit time is 1680000Nm 3 / h, when the flue gas enters the electrostatic precipitator (1), the flow velocity is 15m / s;

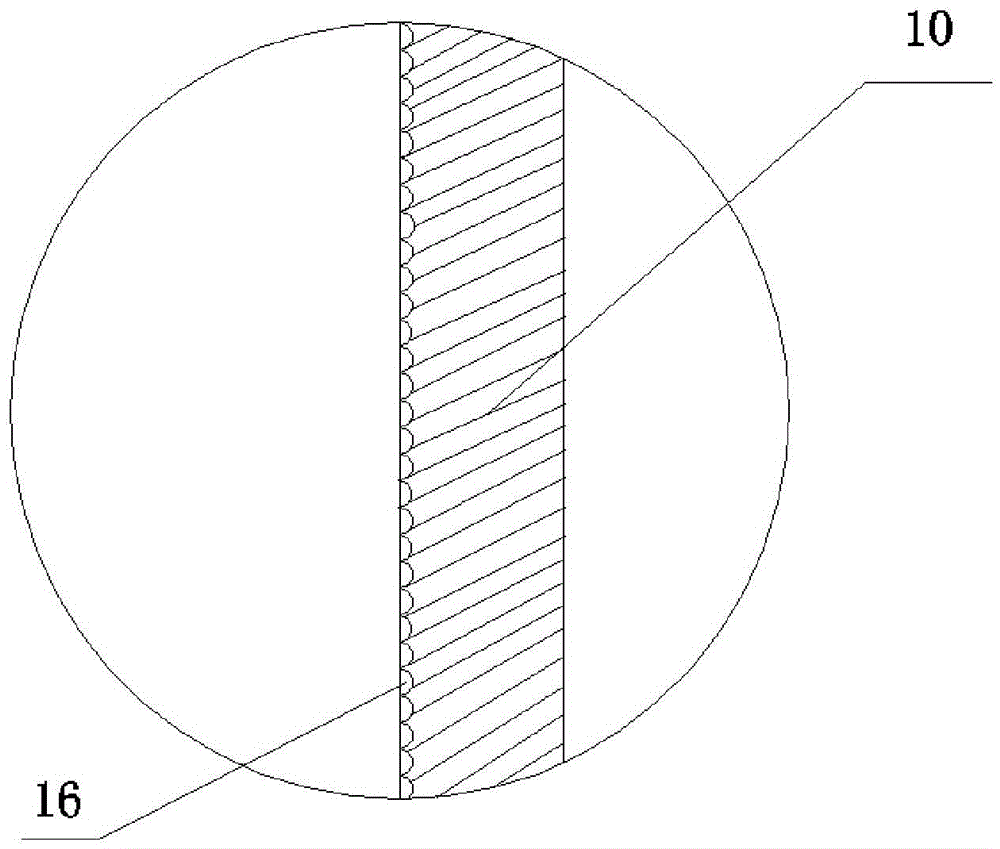

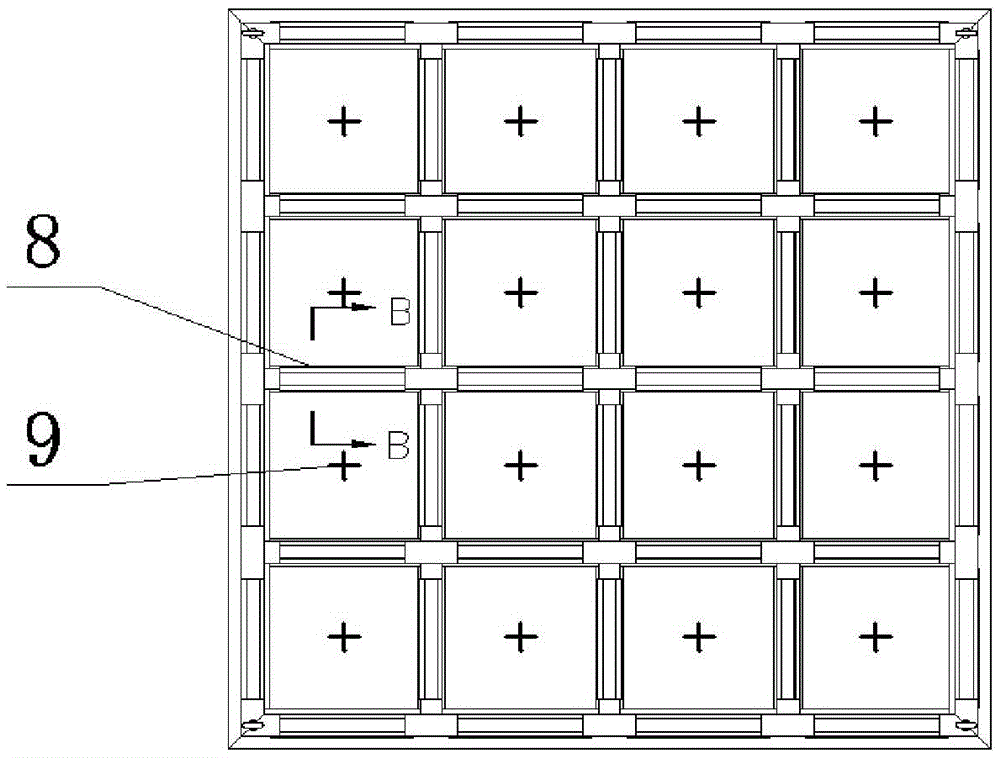

[0048] The anode plates (10) of the wet electrostatic precipitator are arranged in a cuboid shape, the cathode wire (9) of the wet electrostatic precipitator is a prickly wire, and its material is stainless steel, and the anode plate (10) of the wet electrostatic precipitator is made of stainless steel Material; the upper end of the wet electrostatic precipitator anode plate (10) is provided with a water distribution pipe (15) wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com