Method for desulfurized slurry dechlorination

A desulfurization slurry and dechlorination technology, applied in the field of desulfurization slurry dechlorination, can solve problems such as environmental pollution and serious problems, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

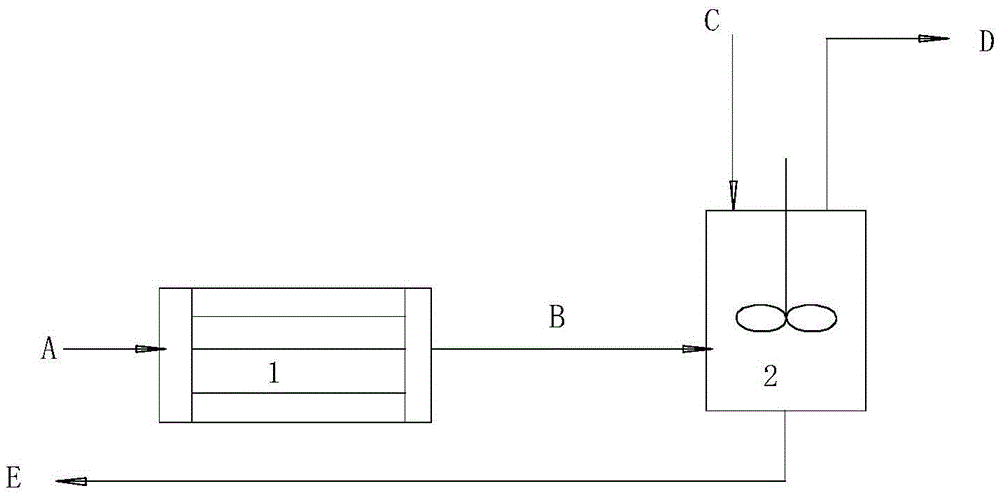

[0023] figure 1 Medium plate ozone generator 1, bubbling reactor 2; air A, ozone B, filtrate C, chlorine gas D, dechlorinated filtrate E.

[0024] Using air A as a raw material, ozone B is generated in the plate type ozone generator 1; when the chloride ion content in the slurry is 5000 mg / L, the desulfurized gypsum dehydration filtrate C is passed through the bubbling reactor 2, and ozone B is continuously introduced into the kettle, Through the bubbling reaction, chlorine gas D is released, and the chlorine gas D is sent to post-treatment, and the dechlorination filtrate E has a chloride ion content of 1000mg / L and is sent back to the absorption tower, thereby reducing the chlorine content in the slurry and maintaining the chlorine ion content in the desulfurization slurry≯5000mg / L.

[0025] Implementation effect: filtrate dechlorination rate ≥ 80%.

[0026] The beneficial effects of the present invention are as follows: (1) Instead of directly dechlorinating the slurry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com