Casting film production equipment

A kind of production equipment and cast film technology, applied in the field of cast film production equipment, can solve the problems of bridge between powder material and blanking material, low production efficiency, unreasonable overall design and arrangement of cast film production line, etc., and achieve high precision tension Control and ensure the effect of tension control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

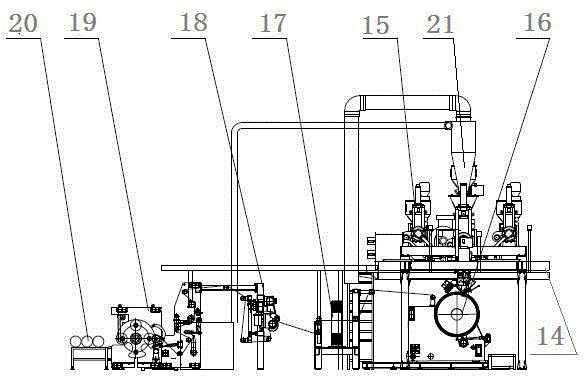

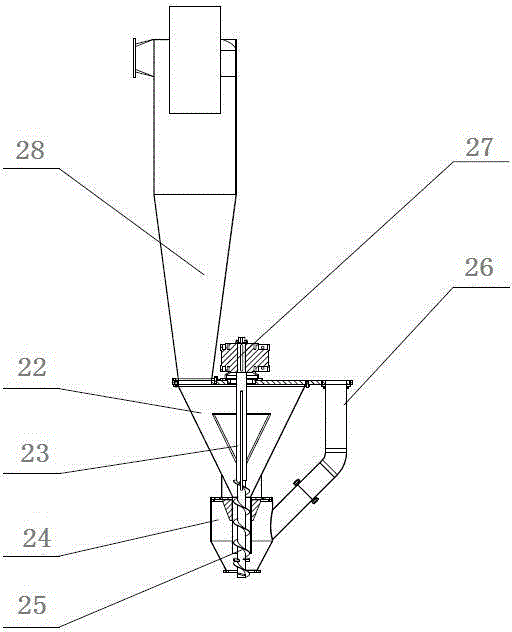

[0030] Such as figure 1 , figure 2 and image 3 As shown, a casting film production equipment, the frame 14 is provided with an extrusion system 15, and the casting system 16, a thickness measurement system 17, a traction pendulum system 18, a retracting system 15 are sequentially provided below the extrusion system 15. Coil system 19 and film unloading device 20, the extrusion system 15 includes a feeding device 21, including a first hopper 22 and a second hopper 24 that are vertically arranged in sequence, and the discharge port of the first hopper 22 is located at the second In the second hopper 24, the first hopper 22 is provided with a screw, and the screw includes a screw stirring section 23 for stirring the powder and a screw conveying section 25 for delivering the powder to the extruder. A cyclone separator 28 is connected to the inlet of a hopper. One side of the second hopper 24 is connected with the new material feeding pipe 26; the screw rod is driven to rotate...

Embodiment 2

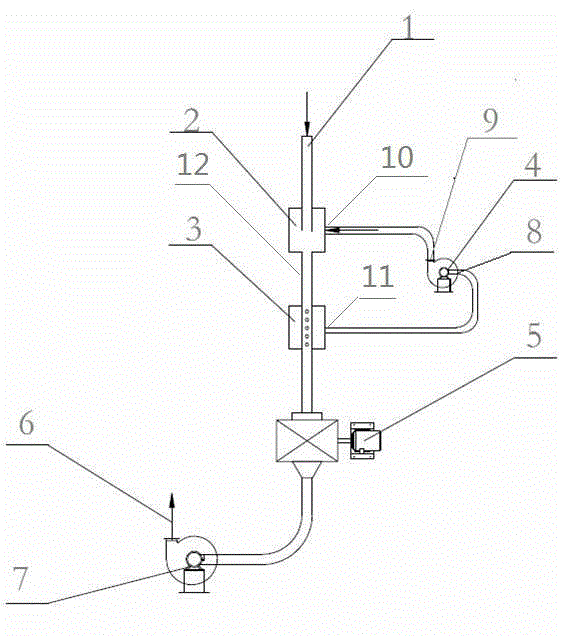

[0040] Embodiment two is different from embodiment one except that the edge material recovery system is different, and other are basically the same, as Figure 4 As shown, the scrap recovery system includes a scraper pipeline 1, a suction device connected to the scraper pipeline and a crusher 5 connected to the suction device, and the suction device includes a negative pressure suction box 2, Exhaust box 3 and negative pressure suction fan 4, the suction port of described negative pressure suction fan 4 is connected with exhaust box 3, and the air outlet of described negative pressure suction fan 4 is connected with negative pressure suction box 2, The negative pressure suction box 2 is sequentially connected to the exhaust box 3 and the crusher 5 through the discharge pipe 12 , and the negative pressure suction box 2 is also connected to the edge material pipeline 1 .

[0041] There are two discharge pipes, namely the first discharge pipe 12 and the second discharge pipe 14, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com