A river network mud crawler transport vehicle

A transport vehicle and crawler-type technology, which is applied to the field of river network mud and swamp crawler transport vehicles, can solve the problems of inability to complete construction tasks, difficult transportation of electrical construction materials, long length of a single piece of tower material, etc., saving manpower, Improve the depth of wading and the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

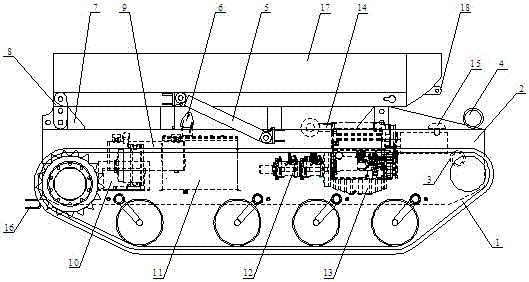

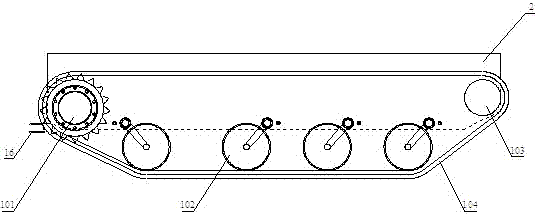

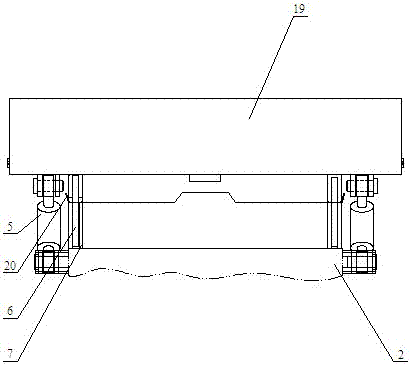

[0042] Such as Figure 1~3As shown, a crawler transport vehicle for river net mud and swamp comprises a walking chassis 1, and the direction of travel of the walking chassis 1 is defined as the front, and the walking chassis 1 includes driving wheels 101, guide wheels 103, road wheels 102, frame and crawlers 104, the guide wheel 103 and the driving wheel 101 are respectively located on the front and rear sides of the walking chassis 1, the road wheel 102 is located between the driving wheel 101 and the guide wheel 103 and the diameter of the road wheel 102 is about 500 mm, and the road wheel 102 adopts a torsion bar The spring-type independent suspension is installed, and the crawler belt 104 adopts a double-induced tooth type made of rubber. On the walking chassis 1, a box body 2 is fixed, and the box body 2 is in the shape of a manger, and the bottom and surrounding sides of the box body 2 are closed. Two ear plates 16 are fixed on the lower end of the casing 2 rear side, a...

Embodiment 2

[0048] Such as Figure 11 , Figure 12 As shown, a kind of crawler transport vehicle for river net and swamp keeps the components in Embodiment 1 unchanged, and only transforms the loading device in Embodiment 1 into two corresponding first support frame bodies 26 before and after, and the first support The frame body 26 is inserted on the supporting connecting frame 7 . The first supporting frame body 26 includes a first supporting platform 201 crimped on the supporting connecting frame 7, the first supporting platform 201 is strip-shaped and extends along the left-right direction, the left and right sides of the first supporting platform 201 upper surface Both ends of the right are fixed with a first baffle 202, the outer surface of the first baffle 202 is fixed with a first hook 204, and the bottom of the first support platform 201 is provided with a left and right corresponding insertion rod 203, the The insertion rod 203 is adapted to the slot on the upper surface of th...

Embodiment 3

[0051] Such as Figure 13~18 As shown, a river network mud crawler transport vehicle keeps the components in Embodiment 1 unchanged, and only the loading device is replaced. The loading device includes a cargo bucket 17, a second support frame body 30 and a third support frame body 31. The cargo bucket 17 is located behind the walking chassis 1, and a connecting rod 29 is arranged between the walking chassis 1 and the cargo bucket 17. , the front and rear ends of the connecting rod 29 are hingedly installed with the second ear plate 16 and the first ear plate 18 respectively, the second support frame body 30 is installed in the box body 2, and the third support frame body 31 is installed in the cargo bucket 17 superior.

[0052] Described second support frame body 30 comprises second support platform 301, and described second support platform 301 is bar-shaped and is perpendicular to the front and back direction that transport vehicle travels, and the left and right ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com