Nano magnetic powder catalytic oxidation and wastewater treatment system

A sewage treatment system, photocatalytic oxidation technology, applied in the direction of oxidized water/sewage treatment, light water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve recovery difficulties, mixed layers of heterogeneous filter beds, adsorption Easy to desorb and difficult to achieve the effect of increasing the effective contact area, strengthening the adsorption and interception effect, and improving the photocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

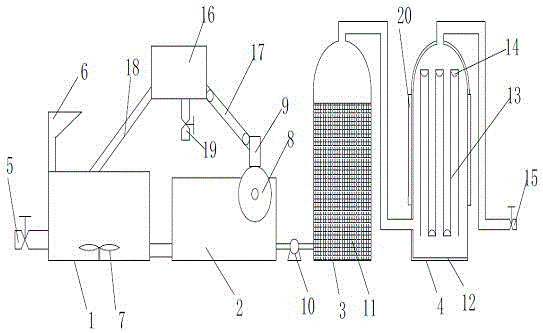

[0017] see figure 1 , the present invention provides an embodiment: a sewage treatment system consisting of a pretreatment unit 1, a primary filter unit 2, a secondary filter unit 3 and a photocatalytic oxidation unit 4, the pretreatment unit 1 is an open container, the lower part A water inlet 5 is provided, a nano-magnetic powder feeding device 6 is provided on the top of the pre-treatment unit 1, and a stirring device 7 is provided at the inner bottom of the pre-processing unit 1, and nano-magnetic powder is put into the pre-processing unit 1, and stirred by the stirring device 7 , so that the nano-magnetic powder is fully mixed with the sewage, so that the nano-magnetic powder can fully absorb and intercept the polymer and suspended matter in the sewage;

[0018] The pretreatment unit 1 is connected with the primary filter unit 2 through a pipeline, and the upper part of the primary filter unit 2 is provided with a magnetic drum 8 and a magnetic powder recovery device 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com