Polymer membrane and preparation method thereof

A polymer film and copolymer technology, applied in the production of bulk chemicals, etc., can solve the problems of narrow molecular weight distribution of polypropylene, poor processing fluidity, and high ULDPE addition amount, and achieve simplified selection and processing procedures, good impact resistance. performance, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] According to a preferred embodiment of the present invention, the polypropylene composition is prepared by continuous polymerization in the presence of a Ziegler-Natta catalyst with high stereoselectivity. The continuous polymerization method means that the preparation process includes at least two sequential steps, wherein component (a) (i.e. crystalline polypropylene A) and component (b) (i.e. ethylene-propylene elastic copolymer B) are each in It is prepared in a separate step and, in addition to the first step, the latter step is carried out in the presence of the polymer formed in the previous step and the catalyst used in the previous step.

[0032]In the preferred case above, since the polypropylene composition is prepared using a Ziegler-Natta catalyst with high stereoselectivity, the molecular weight distribution of the polypropylene composition and the molecular weight distribution of its component (a) are both greater than 4 , preferably greater than 4.5, mor...

Embodiment 1

[0107] (1) Preparation of polypropylene composition

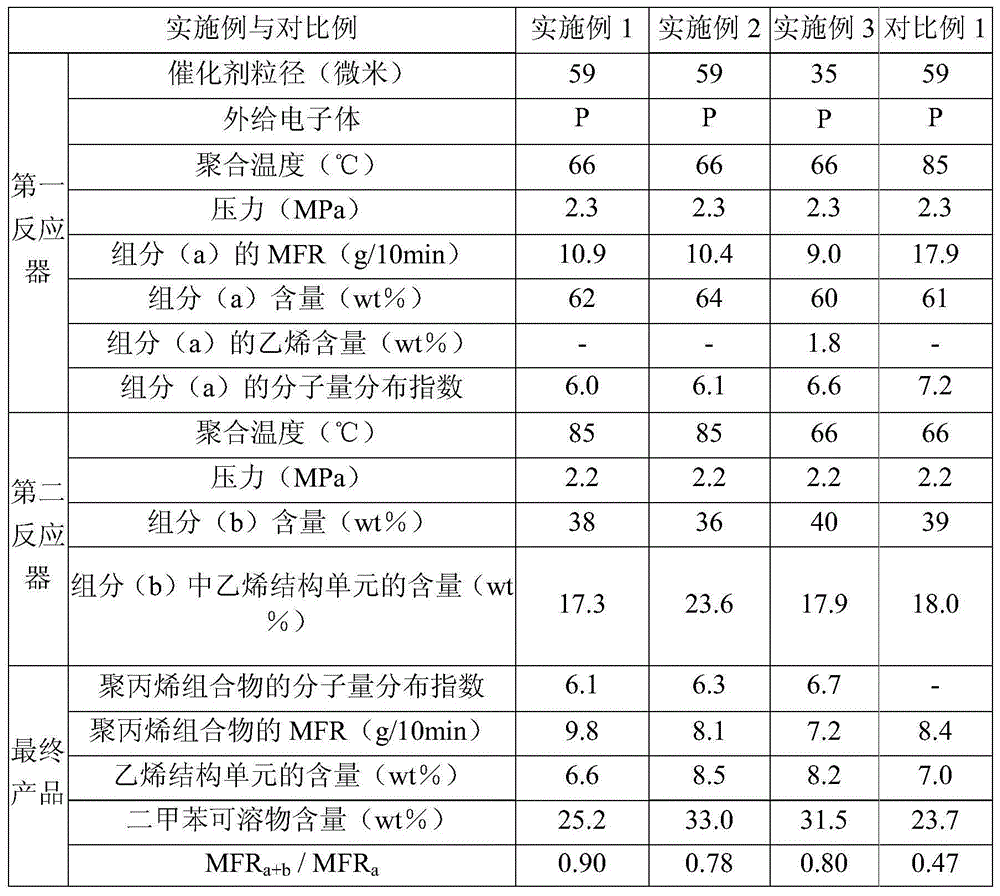

[0108] The polymerization reaction was carried out on the above-mentioned horizontal gas-phase polypropylene pilot plant, and the particle size of the catalyst used was 59 microns, and the reaction was carried out according to the above-mentioned method. The external electron donor used is diisopropyldimethoxysilane, the polymerization reaction in the first reactor is propylene homopolymerization, the polymerization temperature is 66°C, the reaction pressure is 2.3 MPa, and the residence time is about 90 minutes. The second reactor is used for propylene copolymerization to prepare component (b). Ethylene and propylene are added into the reactor. The polymerization temperature is 85° C., the reaction pressure is 2.2 MPa, and the residence time is 60 minutes. The polymer obtained by the reaction is subjected to degassing and wet nitrogen deactivation treatment to obtain a polypropylene composition. The reaction conditions an...

Embodiment 2

[0113] (1) Preparation of polypropylene composition

[0114] A polypropylene composition was prepared according to the method of Example 1, except that the composition and content of component (b) were changed. The reaction conditions and composition properties are shown in Table 1.

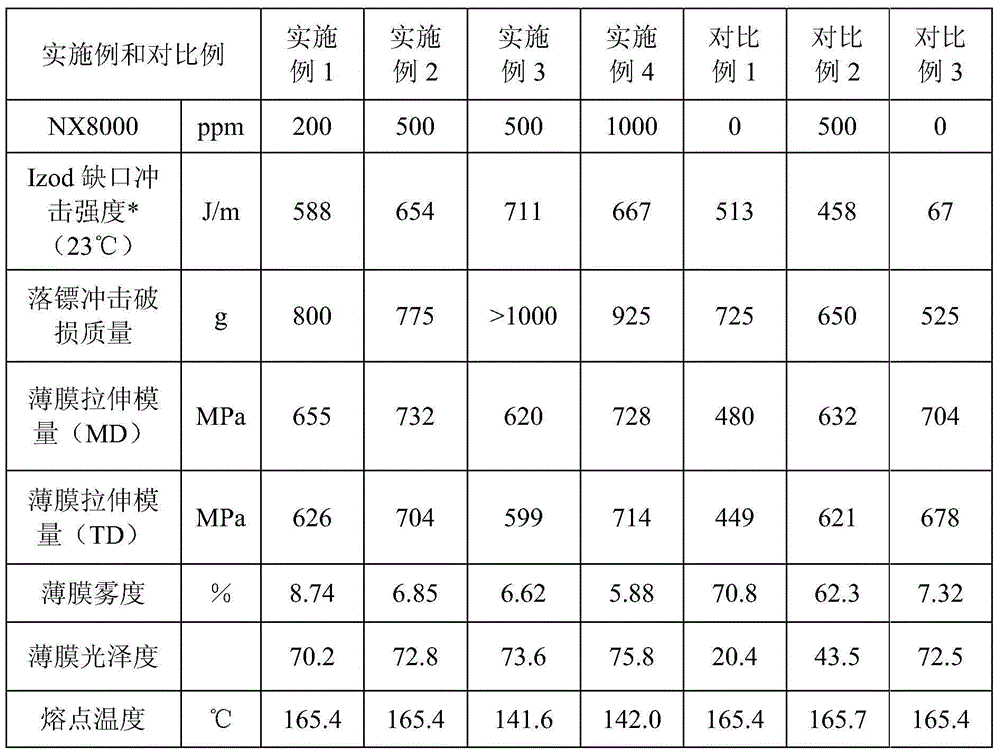

[0115] (2) Preparation of polymer film

[0116] With embodiment 1, difference is that the content of adding NX8000 is 500ppm. A polymer film with an average thickness of 25 microns was obtained, and its properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com