A kind of high CTI environment-friendly flame-retardant reinforced PBT composite material and preparation method thereof

A composite material and environmentally friendly technology, applied in the field of composite materials, can solve the problems of low CTI and non-environmental protection of flame retardants, and achieve the effects of improving environmental protection performance, reducing additives, and facilitating industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

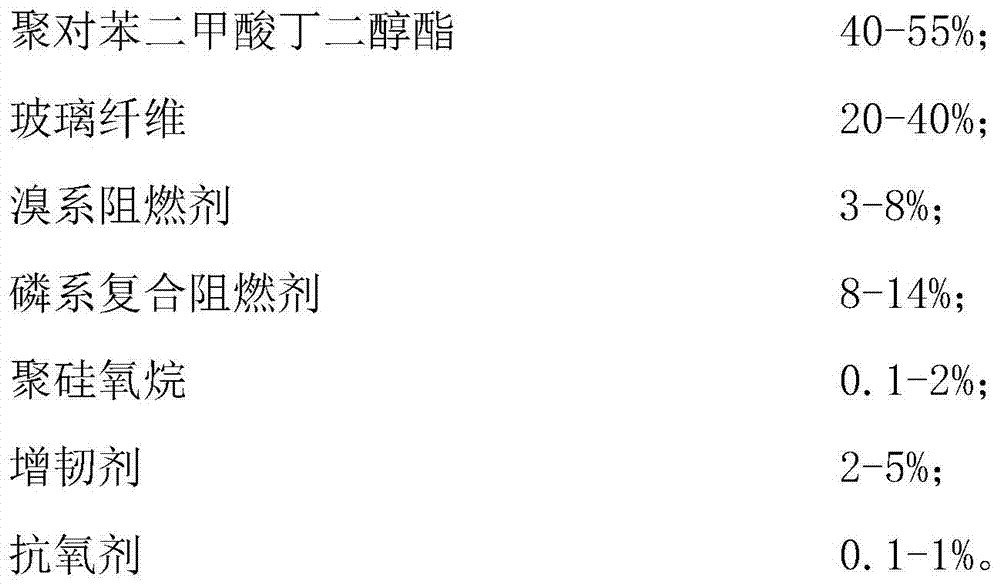

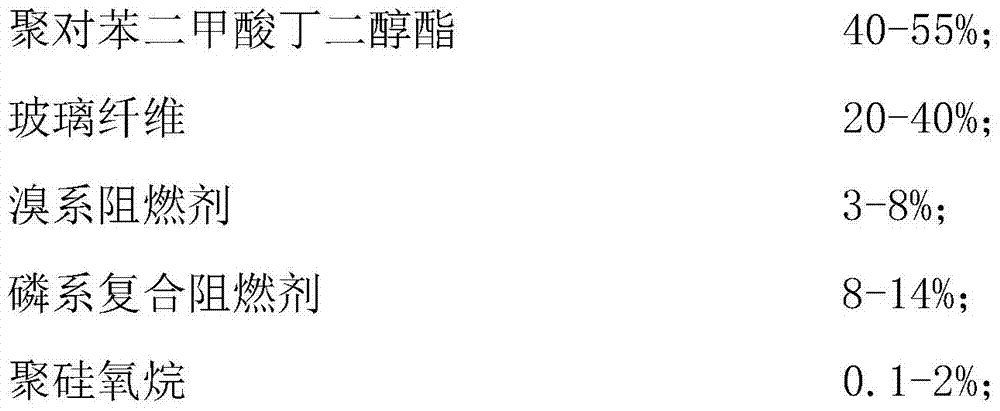

[0033] Correspondingly, the embodiment of the present invention also provides a method for preparing a high CTI environmentally friendly flame-retardant reinforced PBT composite material, comprising the following steps:

[0034] S01. Weigh each component according to the formula of the above-mentioned high CTI environment-friendly flame-retardant reinforced PBT composite material;

[0035] S02. The above-mentioned components are mixed to obtain a mixed material;

[0036] S03. Using a twin-screw extruder to melt-extrude the mixed material, wherein the processing temperature of the twin-screw extruder is 220-250°C.

[0037] Specifically, in the above-mentioned step S01, the formulation components of the high-CTI environment-friendly flame-retardant reinforced PBT composite material and their preferred conditions are as described above, and will not be repeated here to save space.

[0038] In the above-mentioned step S02, the method of mixing the above-mentioned components is no...

Embodiment 1

[0043] A high CTI environment-friendly flame-retardant reinforced PBT composite material, based on the total weight of the high-CTI environment-friendly flame-retardant reinforced PBT composite material as 100%, including the components in weight percentage as shown in Example 1 of Table 1.

[0044] The preparation method of described high CTI environment-friendly fire-retardant reinforced PBT composite material, comprises the following steps:

[0045] S11. Weigh each component according to the formula of the above-mentioned high CTI environment-friendly flame-retardant reinforced PBT composite material;

[0046] S12. Mixing the above-mentioned components to obtain a mixed material;

[0047] S13. Using a twin-screw extruder to melt-extrude the mixed material, wherein the processing temperature of the twin-screw extruder is 220-250°C.

Embodiment 2

[0049] A high CTI environment-friendly flame-retardant reinforced PBT composite material, based on the total weight of the high-CTI environment-friendly flame-retardant reinforced PBT composite material as 100%, including the components in weight percentage as shown in Example 2 of Table 1.

[0050] The preparation method of the high CTI environment-friendly flame-retardant reinforced PBT composite material is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com