Nano high-efficiency catalytic flame-retardant functional master batch and preparation method thereof

A functional masterbatch and nano-catalysis technology, which is applied in the field of nano-high-efficiency catalytic flame-retardant functional masterbatch and its preparation, can solve the problems that the large amount of zirconium phosphate damages the mechanical properties of materials, is unfavorable for industrial production, and has poor compatibility. Catalytic flame retardant effect, improvement of layer gap and compatibility, and effect of avoiding hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

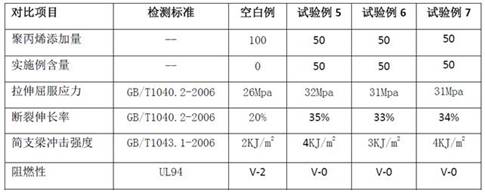

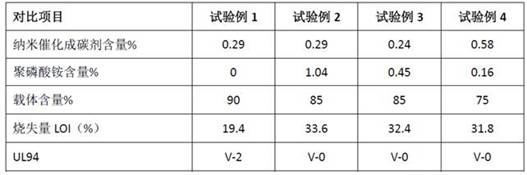

Examples

Embodiment 1

[0030] Weigh 60kg of dispersing solvent polyethylene glycol and 5kg of nano-zirconium phosphate into the reaction kettle, start high-speed stirring, the temperature is 120°C, the speed is 1500r / min, and the time is 30 minutes; then put in 10kg of polyamide-amine (PBMAMA) And triethylamine 10kg, temperature is 120 ℃, and mixing speed is 1500r / min, and the time is 6 hours, makes the material test example A of pre-dispersed slurry material of nano-catalyzed carbon forming agent.

[0031] Weigh 0.5kg of antioxidant (model B215), 2kg of lubricant (polyethylene wax, molecular weight 3000), 1.5kg of silane coupling agent (KH560), put them into the high-speed mixer, start stirring and keep it for 10 minutes, The stirring rate is 3000 rpm. Prepared functional auxiliary component example 1#;

[0032] Weigh 5 kg of nano-catalyzed carbon-forming agent pre-dispersed slurry material Test Example A, functional auxiliary component example 1# 5 kg, and carrier component polypropylene 90 kg. ...

Embodiment 2

[0034] Weigh 60kg of dispersing solvent polyethylene glycol and 5kg of nano-zirconium phosphate into the reaction kettle, start high-speed stirring, the temperature is 120°C, the speed is 1500r / min, and the time is 30 minutes; then put in 10kg of polyamide-amine (PBMAMA) And triethylamine 10kg, temperature is 120 ℃, and mixing speed is 1500r / min, and the time is 6 hours, makes the material test example B of pre-dispersed slurry material of nano-catalyzed carbon forming agent.

[0035] Weigh 1kg of ammonium polyphosphate, 0.3kg of antioxidant (model B215), 2kg of lubricant (polyethylene wax, molecular weight 3000), 1.5kg of silane coupling agent (KH560), put them into the high-speed mixer, and start stirring And keep it for 10 minutes, the stirring rate is 3000 rpm. Prepared functional auxiliary component example 2#;

[0036] Weigh 5kg of nano-catalyzed carbon forming agent pre-dispersed slurry material Test Example B, 5kg of functional auxiliary component example 2#, and 90kg...

Embodiment 3

[0038] Weigh 60kg of dispersing solvent polyethylene glycol and 2kg of nano-zirconium phosphate into the reaction kettle, start high-speed stirring, the temperature is 150°C, the speed is 1500r / min, and the time is 60 minutes; then put in 6kg of polyamide-amine (PBMAMA) And triethylamine 14kg, temperature is 150 ℃, and mixing speed is 1500r / min, and the time is 6 hours, makes the material test example C of pre-dispersed slurry material of nano-catalyzed carbon forming agent.

[0039] Weigh 5kg of ammonium polyphosphate, 5kg of antioxidant (model B215), 10kg of lubricant (polyethylene wax, molecular weight 3000), 25kg of silane coupling agent (KH560), put them into the high-speed mixer, start stirring, the Said stirring rate was 2000 rpm, and kept for 10 minutes. Prepared functional auxiliary component example 3#;

[0040] Weigh 10kg of nano-catalyzed carbon forming agent pre-dispersed slurry material Test Example C, 5kg of functional auxiliary component example 3#, and 85kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com