Oil-based drilling fluid extracting and cutting agent and preparation method thereof

A technology of oil-based drilling fluid and cutting agent, applied in the field of drilling, can solve the problems of easy desorption of organic soil, reduce the dissolution rate, reduce the service life of oil-based drilling fluid, etc. The effect of improving temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

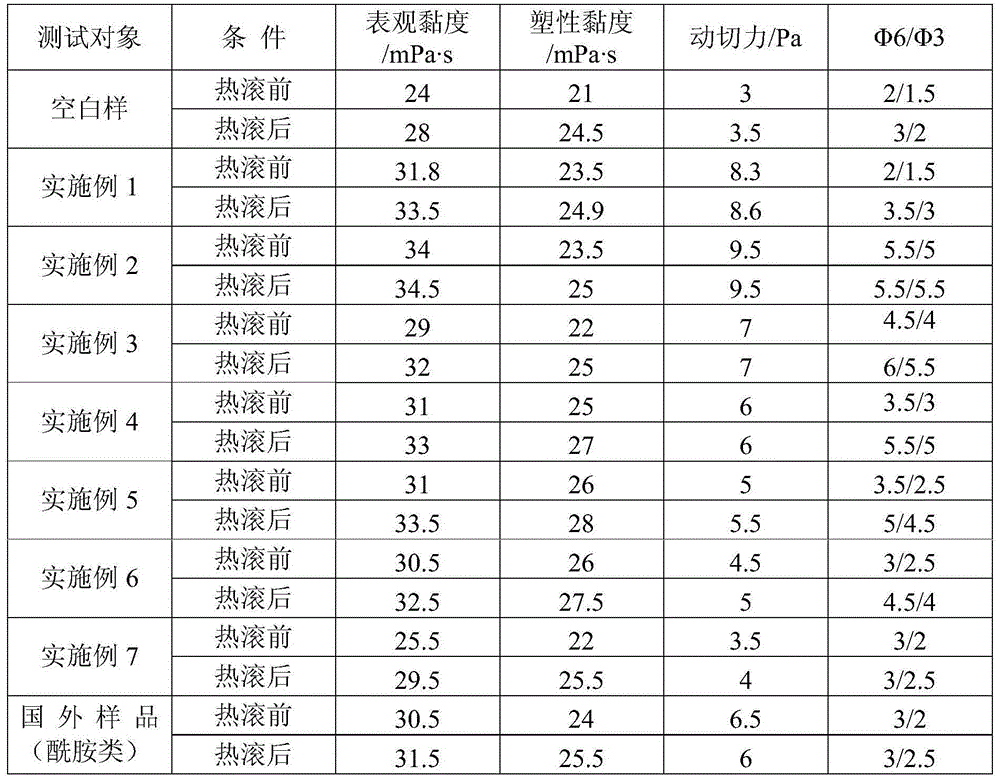

Examples

Embodiment 1

[0038] step 1

[0039] First add 9.8g maleic anhydride and 20.83g styrene to 49g toluene, then add them to the reactor, heat to 80°C, add 0.1532g azobisisobutyronitrile to the solution, and react under nitrogen protection for 3 Hours, the polymerization reaction produces a mixture T.

[0040] step 2

[0041] Under stirring conditions, 9.209g of glycerol and 0.19g of p-toluenesulfonic acid were added to the mixture T, and the stirring reaction was continued for 4 hours to obtain the crude oil-based drilling fluid cutting agent TQ.

[0042] step 3

[0043] The crude cutting agent TQ was suction filtered to remove toluene, and then dried in a constant temperature blast drying oven at 120°C to constant weight. After mechanical crushing, the oil-based drilling fluid cutting agent is obtained.

Embodiment 2

[0045] step 1

[0046] First add 9.8g maleic anhydride and 4.166g styrene to 147g toluene, then add them to the reactor, heat to 105°C, add 0.2793g azobisisobutyronitrile to the solution, and react under nitrogen protection for 3 Hours, the polymerization reaction produces a mixture T.

[0047] step 2

[0048] Under stirring conditions, 80 g of polyethylene glycol 2000 and 0.449 g of p-toluenesulfonic acid were added to the mixture T, and the stirring reaction was continued for 4 hours to obtain crude oil-based drilling fluid cutting agent TQ.

[0049] step 3

[0050] With embodiment 1 step 3. The solid product obtained by drying is mechanically pulverized to obtain the oil-based drilling fluid cutting agent.

Embodiment 3

[0052] step 1

[0053] First add 9.8g maleic anhydride and 10.415g styrene to 98g toluene, then add them to the reactor, heat to 80°C, add 0.2022g azobisisobutyronitrile to the solution, and react under nitrogen protection for 3 Hours, the polymerization reaction produces a mixture T.

[0054] step 2

[0055] Under stirring conditions, 6.1333g of glycerol and 0.1194g of p-toluenesulfonic acid were added to the mixture T, and the stirring reaction was continued for 4 hours to obtain the crude oil-based drilling fluid cutting agent TQ.

[0056] step 3

[0057] With embodiment 1 step 3. The oil-based drilling fluid cutting agent is obtained after the solid product obtained by drying is mechanically pulverized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com