Modified nano silicon dioxide, high-temperature-resistant tackifying and shear strength improving agent and preparation methods and applications of modified nano silicon dioxide and high-temperature-resistant tackifying

A nano-silica, high-temperature-resistant technology, applied in the direction of chemical instruments and methods, silicon organic compounds, drilling compositions, etc., can solve the problem of lowering the strength of the drilling fluid system, losing the cutting effect, affecting the ROP, etc. Problems, to achieve excellent solid phase suspension ability, improve low shear rate viscosity, and improve structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

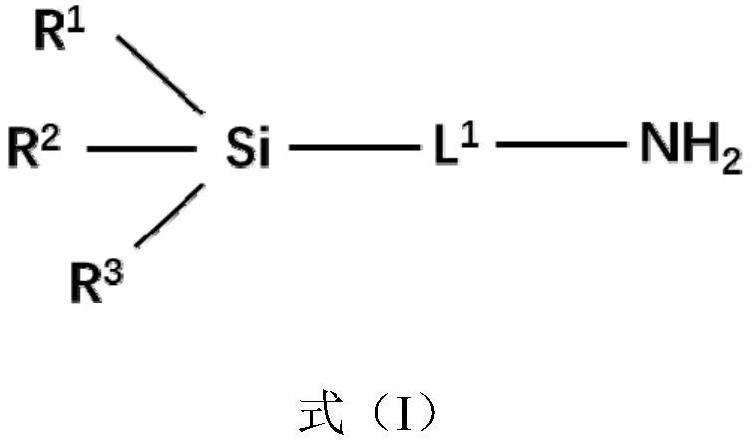

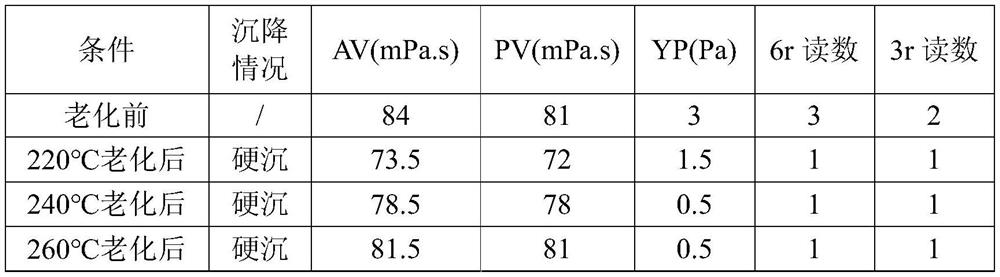

[0044] The present embodiment provides a modified nano-silicon dioxide and a high-temperature anti-viscosity and cutting-lifting agent, and the preparation method thereof is as follows:

[0045] In 100mL absolute ethanol, add 2g nano-silicon dioxide and ultrasonically disperse 30min, then add aminosilane coupling agent KH550 (the nano-silicon dioxide in silicon and aminosilane coupling agent KH550 The amino molar dosage ratio is 1: 0.2) mix homogeneously, and raise the temperature to 50 ℃, react 90min, then suction filtration obtains the first reaction product; The first reaction product and octadecane unsaturated fatty acid dimer are added in the there-necked flask (nanometer in terms of silicon). The molar ratio of the carboxyl groups of silica and octadecane unsaturated fatty acid dimer is 1:0.1), under the condition of nitrogen flow, with a stirring speed of 100r / min, the temperature is raised to 100 ° C, maintained for 30min, and then the stirring speed is increased to 25...

Embodiment 2

[0048] The present embodiment provides a modified nano-silicon dioxide and a high-temperature anti-viscosity and cutting-lifting agent, and the preparation method thereof is as follows:

[0049] In 100mL absolute ethanol, add 2g nano-silicon dioxide and ultrasonically disperse for 30min, then add aminosilane coupling agent KH550 (the molar ratio of the amine groups of silica and aminosilane coupling agent KH550 in terms of silicon is 1:0.6 ) mix evenly, and raise the temperature to 60 DEG C and react for 120min, then suction filtration to obtain the first reaction product; the first reaction product and octadecane unsaturated fatty acid dimer are added to the there-necked flask (nano dioxide in silicon The molar ratio of carboxyl groups of silicon and octadecane unsaturated fatty acid dimer is 1:0.05), under the condition of nitrogen, with stirring speed of 100r / min, the temperature is raised to 100℃, maintained for 30min, and then the stirring speed is increased to 250r / min m...

Embodiment 3

[0052] The present embodiment provides a modified nano-silicon dioxide and a high-temperature anti-viscosity and cutting-lifting agent, and the preparation method thereof is as follows:

[0053] In 100mL absolute ethanol, add 2g nano-silicon dioxide and ultrasonically disperse 30min, then add aminosilane coupling agent KH550 (the nano-silicon dioxide in silicon and aminosilane coupling agent KH550 The amino molar dosage ratio is 1: 0.2) mix uniformly, and raise the temperature to 50 DEG C and react for 90min, then suction filtration to obtain the first reaction product; the first reaction product and octadecane unsaturated fatty acid dimer are added to the there-necked flask (nano-dimer in terms of silicon). The molar ratio of carboxyl groups of silicon oxide and octadecane unsaturated fatty acid dimer is 1:0.01), under the condition of nitrogen, with stirring speed of 100r / min, heat up to 100℃, maintain for 30min, and then increase the stirring speed to 250r / min and the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plastic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com